Method for shaping and toughening fiber reinforced composite material

A composite material and fiber-reinforced technology, applied in the field of composite materials, can solve the problems of relatively stringent solubility requirements of thermoplastic resins, inability to penetrate fibers or adhesion and toughening effects, and small two-phase interface area, etc., to achieve high temperature resistance and increase Stiffness, the effect of meeting large-scale applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

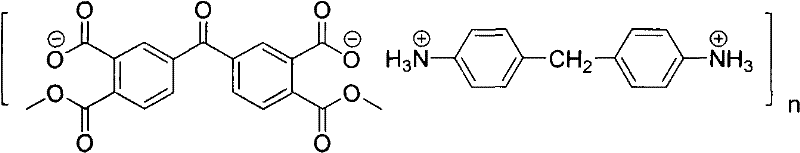

[0020] (1) Crush the polyimide foaming powder whose structural formula is as follows into a powder with a size of about 5 μm. The methanol content in the foaming powder is 10%, and it is evenly dispersed on the surface of the continuous carbon fiber fabric, and the surface density is 10 g / m 2 , the ambient temperature is room temperature; after passing through the heating zone at 180°C for 5s, the fabric with foam powder is obtained.

[0021]

[0022] (2) When the layup is finalized, place the prefabricated body obtained by the layup in an oven, heat it to 300°C and keep it for 1 hour by vacuum bag pressing, so that the polyimide foaming powder is fully imidized and developed. bubbles and form a thermoplastic polymer bridge structure for toughening between the layers.

Embodiment 2

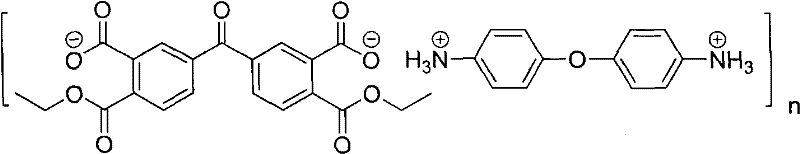

[0024] (1) Pulverize the polyimide foaming powder whose structural formula is as follows into a powder with a size of about 20 μm. The ethanol content in the foaming powder is 30%, and it is evenly dispersed on the surface of the continuous carbon fiber fabric, and the surface density is 25g / m 2 , the ambient temperature is room temperature; after passing through a heating zone at 160°C for 15s, a fabric loaded with foam powder is obtained.

[0025]

[0026] (2) When the layer is finalized, put the prefabricated body obtained by the layer in an oven, adopt the method of vacuum bag pressure setting, heat to 280 ° C and keep it for 1.5 hours, so that the polyimide foaming powder is fully imidized. bubbles and form a thermoplastic polymer bridge structure for toughening between the layers.

Embodiment 3

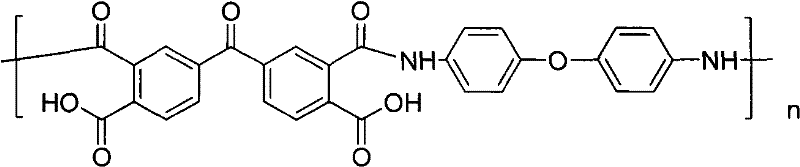

[0028] (1) The polyimide foaming powder whose structural formula is shown below is pulverized into a powder with a size of about 40 μm. The solvent DMF content in the foaming powder is 15%, and it is evenly dispersed on the surface of the continuous carbon fiber fabric, and the surface density is 25g / m 2 , the ambient temperature is room temperature; after passing through a heating zone at 180°C for 30s, a fabric loaded with foam powder is obtained.

[0029]

[0030] (2) When the layup is finalized, place the prefabricated body obtained by the layup in an oven, heat it to 250°C and keep it for 2 hours by vacuum bag pressing, so that the polyimide foaming powder is fully imidized and developed. bubbles and form a thermoplastic polymer bridge structure for toughening between the layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com