Novel sufficient metal air battery oxygen electrode and preparation method thereof

A metal-air battery, oxygen electrode technology, applied in battery electrodes, fuel cell parts, circuits, etc., can solve the problems of not finding the electrochemical performance of lithium-air batteries, difficult LiOH aqueous solution to convert metal lithium, precipitation and material corrosion, etc. , to achieve the effect of strong resistance to metal oxide deposition, sufficient gas-liquid-solid three-phase contact, and high catalytic reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

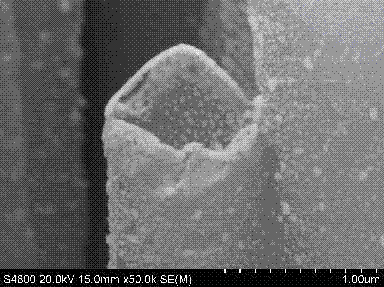

Embodiment 1

[0036] The 50-200 μm thick acid-etched hollow tunnel hole aluminum treated with polytetrafluoroethylene emulsion is used as a gas microchannel (the contact angle to water is greater than 150o, the porosity is greater than 70%, and the pore diameter is 500-1000 nm), the above combination 1 ~ 3 mm thick stainless steel mesh is the gas distribution plate, the two are stacked and placed obliquely at the bottom of the electrode, the inclination angle to the horizontal direction is 30 ~ 50o, and the 0.5 ~ 1.5 mm thick copper mesh is placed on the gas distribution plate as the electrode collector, aluminum The hollow tunnel hole is connected with the mesh of stainless steel mesh and copper mesh to ensure the smooth flow of gas, forming the gas path outside the cathode reaction chamber; using anodized aluminum as the template and natural gas as the carbon source, the pipe diameter is 50 ~ 100 nm prepared by chemical vapor deposition 1. The carbon nanotube array with a tube length of 20...

Embodiment 2

[0039] The 500-1000 μm thick molecular sieve treated with polypropylene emulsion is used as a gas microchannel (the contact angle to water is greater than 120o, the porosity is greater than 60%, and the pore diameter is 100-500 nm), and the 2-5 mm thick platinum mesh combined on it is the gas microchannel. The distribution plate and the electrode current collector are stacked and placed at the bottom of the electrode obliquely, with an inclination angle of 10 to 20o to the horizontal direction. The molecular sieve holes communicate with the meshes of the platinum mesh to ensure the smooth flow of the gas, forming the gas path outside the cathode reaction chamber; Etched the tunnel aluminum hole as a template, and prepared a poly-3,4-ethylenedioxythiophene PEDT array with a tube diameter of 500-1500 nm and a tube length of 50-100 μm by the hypergravity-assisted polymerization method, and assembled the array on the above-mentioned platinum On the net, the hollow tube is aligned w...

Embodiment 3

[0042] Using TiO with surface hydrophobic treatment 2 The array tube is a gas microchannel (the contact angle to water is greater than 90o, the porosity is greater than 90%, and the pore diameter is 50-200 nm), and the 2-5 mm thick titanium mesh is combined on it as a gas distribution plate and an electrode collector. Put it on the bottom of the electrode and place it obliquely, the inclination angle to the horizontal direction is 40 ~ 60o, TiO 2 The array tubes communicate with the meshes of the titanium mesh to ensure the unimpeded flow of gas and constitute the gas path outside the cathode reaction chamber; ZnO arrays with a tube diameter of 100-500 nm and a tube length of 20-50 μm were prepared by self-assembly method, and the array was assembled on the above-mentioned titanium On the net, the hollow tube is aligned with the mesh to ensure that the gas can diffuse smoothly in the tube to form the gas path in the cathode reaction chamber; the hierarchical structure pore car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com