Improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement and preparation method thereof

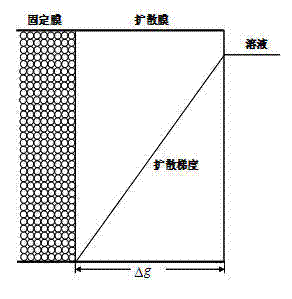

A thin film diffusion gradient and fixed film technology, applied in the MS field, can solve the problems of large fixative particles, unable to meet the requirements of high-resolution analysis, uneven distribution, etc., and achieve the effects of uniform particle distribution, excellent physical strength, and low stretchability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An improved phosphorus immobilized membrane in the determination of thin film diffusion gradients, the preparation method of which is as follows:

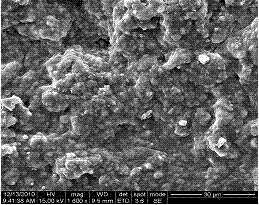

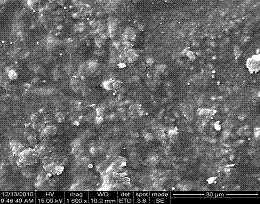

[0029]Weigh 25g of zirconium oxychloride and dissolve it in 600ml of deionized water, then use 25% (volume ratio) ammonia water to adjust the pH of the solution and stabilize it between 6.9-7.1, and wash the resulting precipitate with deionized water for 8-9 times , and finally use a hair dryer to dry its moisture content to between 45 and 55%. Mix 1.8g of prepared zirconium dioxide powder with 7.2ml of acrylamide solution (aqueous solution of 28.5% acrylamide and 1.5% methacrylamide) at a mass volume ratio of 1:4, and grind it with an agate mortar for 10 to 30 minutes. Then use a cell disruptor to sonicate at 20% frequency for 5 to 15 minutes, let it stand for 10 to 30 minutes, remove the precipitate, and then add 4.5 μL of tetramethyldiethylamine (TEMED) and 180 μL of ammonium persulfate solution to the solution (mass rat...

Embodiment 2

[0033] An improved phosphorus immobilized membrane in the determination of thin film diffusion gradients, the preparation method of which is as follows:

[0034] Weigh 25g of zirconium oxychloride and dissolve it in 600ml of deionized water, then use 25% (volume ratio) ammonia water to adjust the pH of the solution and stabilize it between 6.9-7.1, and wash the resulting precipitate with deionized water for 8-9 times , and finally use a hair dryer to dry its moisture content to between 45 and 55%. Mix 1.45g of prepared zirconium dioxide powder with 7.2ml of acrylamide solution (aqueous solution of 28.5% acrylamide and 1.5% methacrylamide) at a mass volume ratio of 1:5, and grind it with an agate mortar for 10 to 30 minutes. Then use a cell disruptor to sonicate at 20% frequency for 5 to 15 minutes, let it stand for 10 to 30 minutes, remove the precipitate, and then add 5.1 μL of tetramethyldiethylamine (TEMED) and 120 μL of ammonium persulfate solution to the solution (mass r...

Embodiment 3

[0036] Example 3, an improved phosphorus immobilized membrane in the determination of a thin film diffusion gradient, its preparation method is basically the same as that of Example 1,

[0037] The difference is that the acrylamide solution is a 35.0% acrylamide aqueous solution.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com