Process for producing urea sulfate ammoniated compound fertilizer

A production process, the technology of urea sulfate, applied in the field of urea sulfate ammoniated compound fertilizer production process, can solve the problems of large amount of steam, high heat required for drying, high moisture content of granulated materials, etc., to improve product quality, save steam consumption, The effect of saving the drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

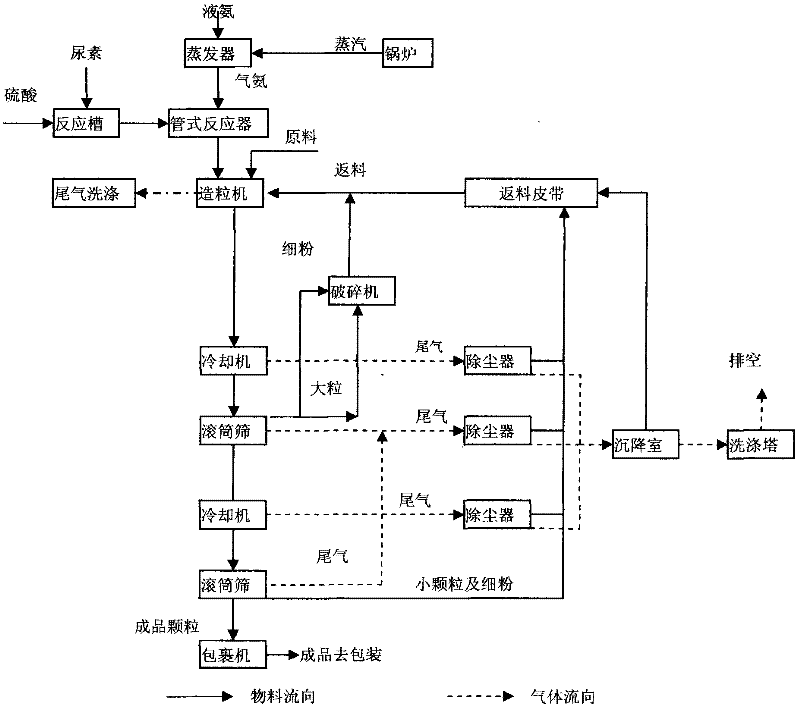

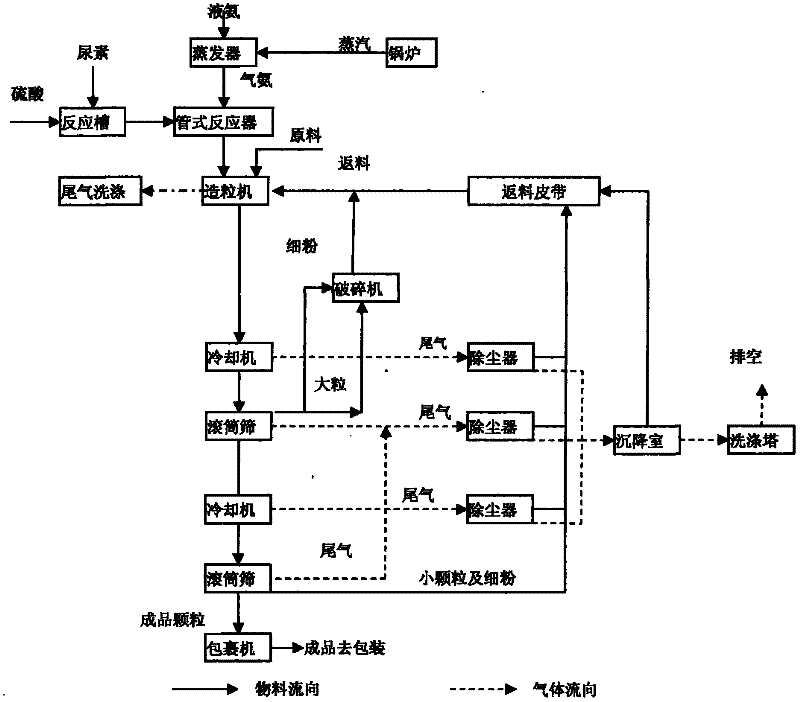

[0026] The production technology of 45 (15-15-15)% urea sulfate ammoniated compound fertilizer, as shown in accompanying drawing, comprises the steps:

[0027] 1. Put 63kg of sulfuric acid and 104kg of urea into the reaction vessel for reaction to generate urea sulfate.

[0028] 2, the urea sulfate that step 1 generates is mixed with 75% urea sulfate solution with granulator tail gas washing solution.

[0029] 3. Evaporate 35kg of liquid ammonia into gaseous ammonia through the evaporator; urea sulfate solution reacts with gaseous ammonia and steam in the tubular reactor to generate a large amount of high-temperature and high-pressure superheated steam to generate ammonium sulfate and urea molten slurry.

[0030] 4. Mix 340kg of monoammonium phosphate, 250kg of potassium chloride, 100kg of ammonium chloride, 27kg of ammonium bicarbonate, 50kg of urea fertilizer and 100kg of filler, crush them and send them to the granulator; The feeding port of the granulator sprays and granu...

Embodiment 2

[0034] The production technology of 48 (16-16-16)% urea sulfate ammoniated compound fertilizer, as shown in the accompanying drawing, comprises the steps:

[0035] 1. Put 63kg of sulfuric acid and 104kg of urea into the reaction vessel for reaction to generate urea sulfate.

[0036] 2, the urea sulfate that step 1 generates is mixed with 75% urea sulfate solution with granulator tail gas washing solution.

[0037] 3. Evaporate 35kg of liquid ammonia into gaseous ammonia through the evaporator; urea sulfate solution reacts with gaseous ammonia and steam in the tubular reactor to generate a large amount of high-temperature and high-pressure superheated steam to generate ammonium sulfate and urea molten slurry.

[0038] 4. Mix 366kg of monoammonium phosphate, 268kg of potassium chloride, 107g of ammonium chloride, 27kg of ammonium bicarbonate, 77kg of urea fertilizer and 271kg of filler, crush them and send them to the granulator; at the same time, ammonium sulfate and urea molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com