Method for directly producing anhydrous spherical calcium chloride from ammonia-soda process waste liquid

A technology of calcium chloride, ammonia alkali method, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems of low production efficiency, complicated process, poor product quality, etc., and achieve production efficiency High, simple process, less equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

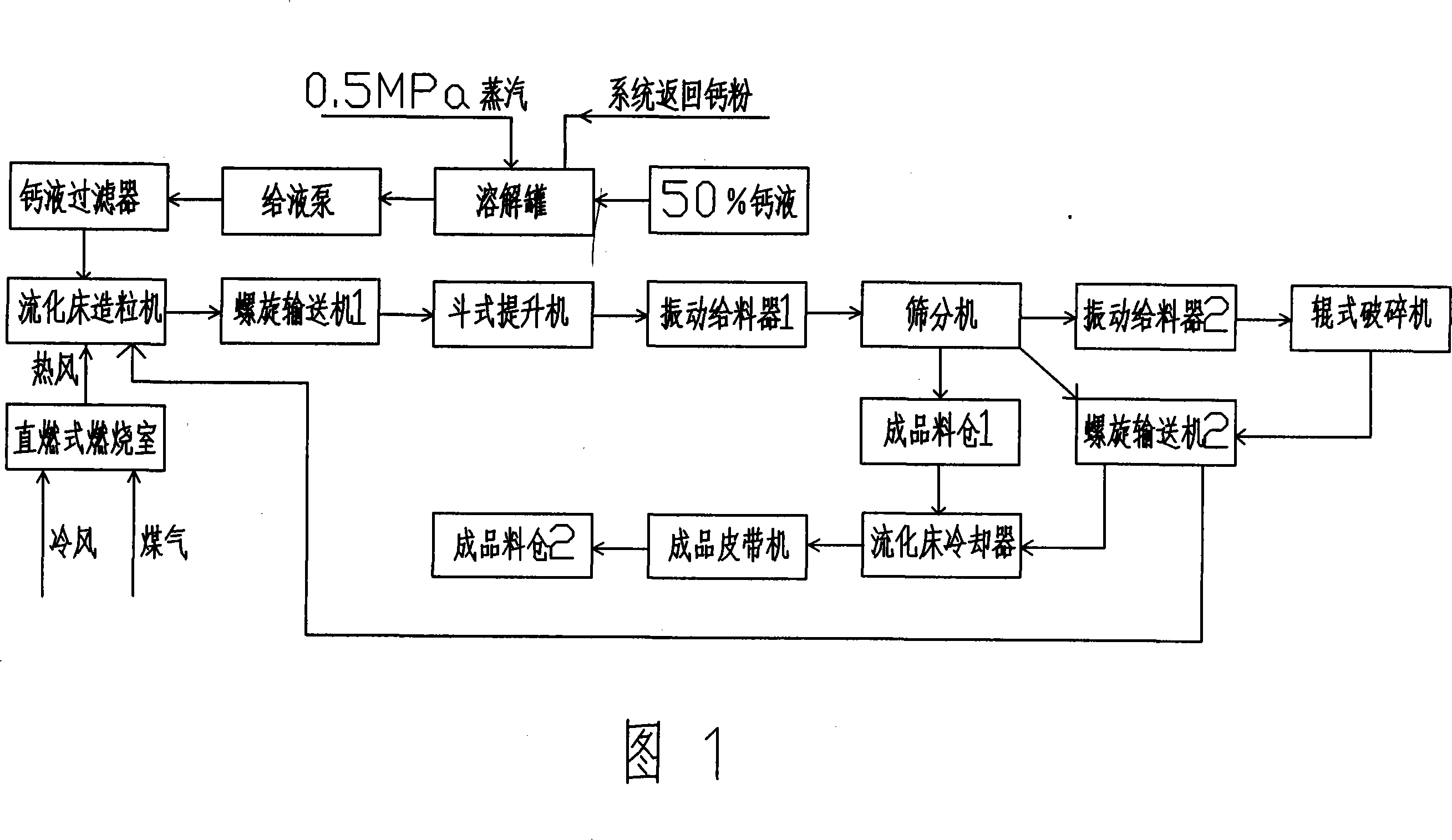

[0017] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0018] As shown, with CaCl 2 About 50% of the calcium liquid is sent from the evaporation workshop to the dissolution tank, and 0.5MPa steam is introduced to heat the calcium liquid to make the temperature of the calcium liquid reach above 120°C. The calcium powder returned by the vacuum system enters the dissolution tank and is dissolved and absorbed by the calcium liquid, so that Calcium solution is thickened to about 62%.

[0019] The above-mentioned concentrated calcium solution is pumped from the feeding liquid to the calcium solution filter for filtration, and then enters the fluidized bed granulator for spray granulation. The calcium liquid ejected from the nozzle of the granulator forms a mist. At this time, it must be dried with hot air to remove most of the water to obtain the finished spherical calcium with a content of ≥94.5%. The drying method is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com