Secondary reheating unit with ultrahigh pressure cylinder and high-intermediate pressure cylinder both provided with additional heat regeneration stages

A technology of ultra-high pressure cylinder and high-medium pressure cylinder, which is applied in the field of secondary reheating units with additional reheating stages for both ultra-high pressure cylinders and high-medium pressure cylinders. The effective enthalpy drop of the cylinder and other issues can be solved to achieve the effects of simplifying the structure, improving the efficiency in the middle and low pressure cylinders, and reducing the steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

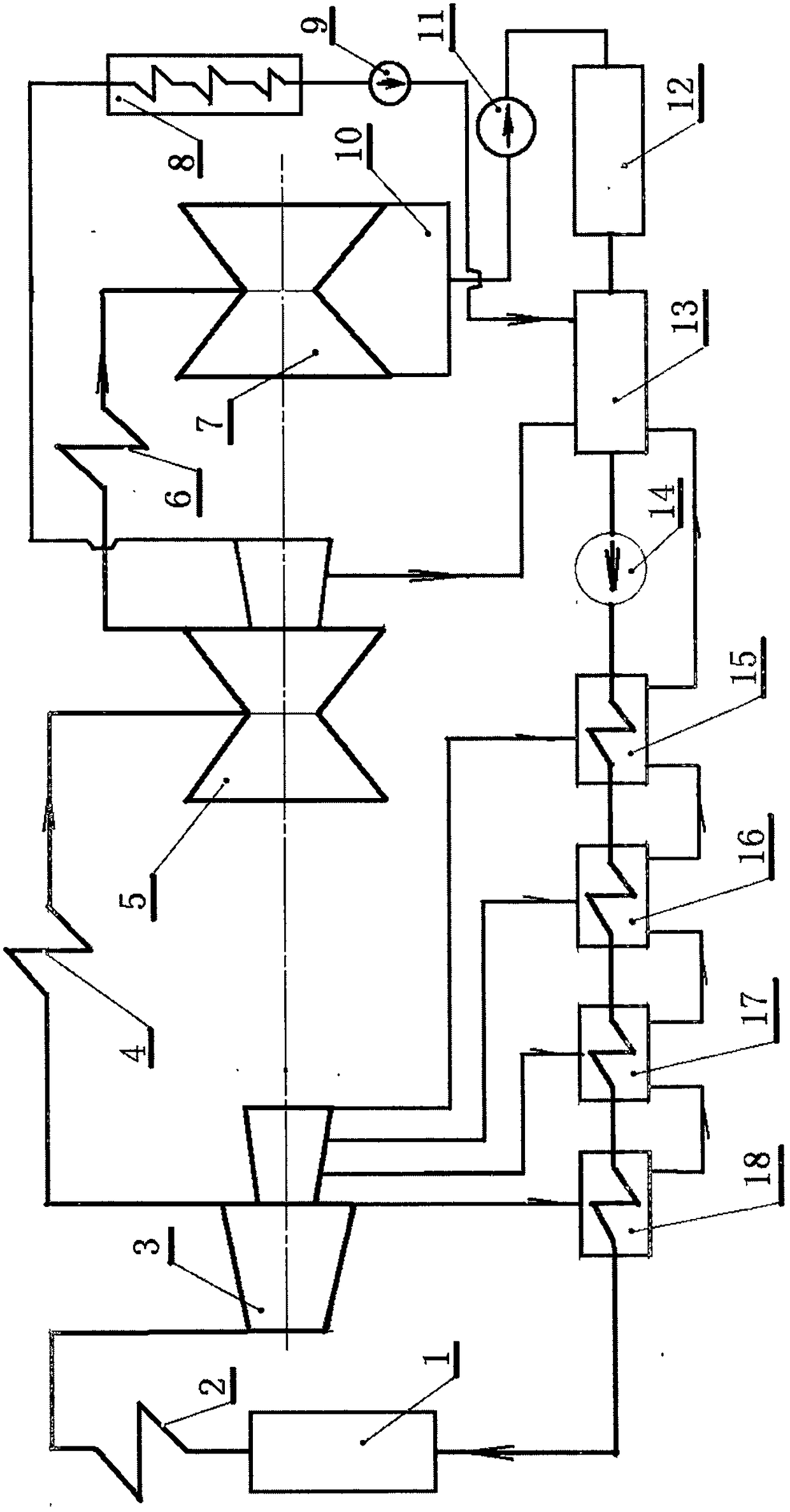

[0071] Combine now figure 1 , taking a 1000MW class, the design value of the turbine side main steam temperature / primary reheat steam temperature / secondary reheat steam temperature is 585°C / 620°C / 620°C as an example to illustrate the implementation of the present invention preferred method.

[0072] A secondary reheating unit with an additional heat recovery stage for both the ultra-high pressure cylinder and the high and medium pressure cylinders of the present invention includes: a boiler water wall and an economizer (1), a boiler superheater system (2), and an additional heat recovery stage stage ultra-high pressure cylinder (3), boiler primary reheater system (4), high and medium pressure cylinder with additional recuperation stage (5), boiler secondary reheater system (6), medium and low pressure cylinder (7) , heater (8), heater drain pump (9), condenser (10), condensate pump (11), ultra-low temperature economizer (12), deaerator (13), electric feedwater pump (14 ), No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com