Rubber transmission belt vulcanizing device and vulcanizing method thereof

A transmission belt and rubber technology, applied in the field of rubber transmission belt vulcanization devices, can solve the problems of reduced safety, waste, poor fluidity, etc., and achieve the effects of reducing the amount of saturated steam, saving equipment investment, and reducing the volume of the steam chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

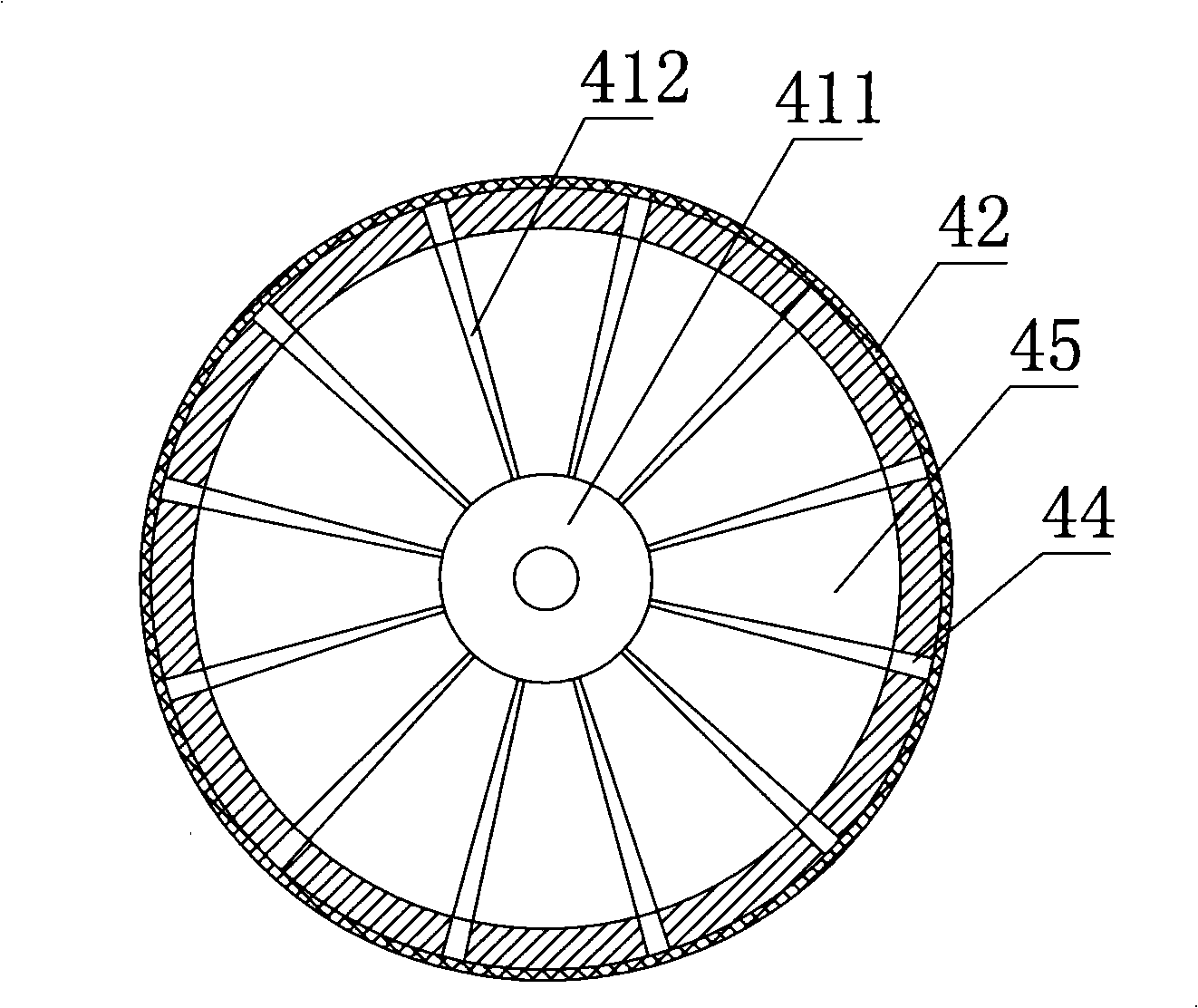

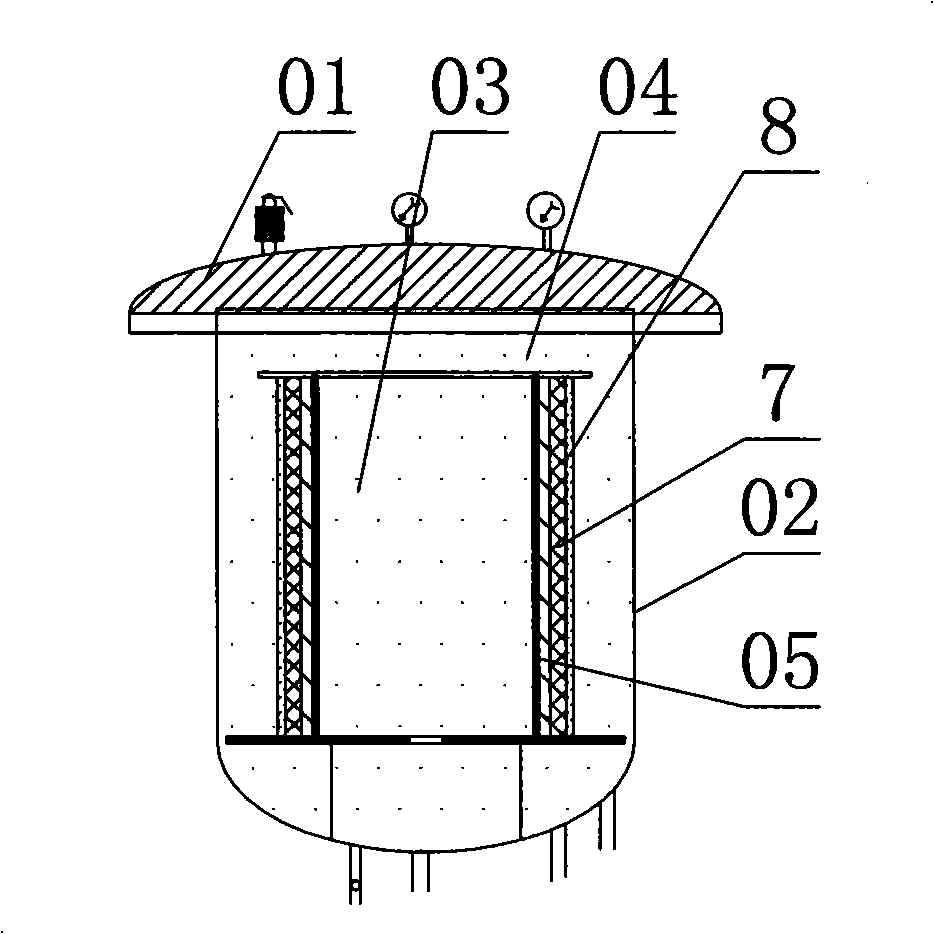

[0019] Figure 1 and figure 2 As shown, it is a rubber transmission belt vulcanization device of the present invention, which includes an outer casing 1, an upper cover plate 2 and a lower bottom plate 3 sealedly connected with the upper and lower end faces of the outer casing 1, and a mold assembly. The outer casing adopts a steel ring cylinder outer casing, and the mold assembly includes a mandrel. The frame body 41 and the mold 42 arranged at the outer ring end of the mandrel frame body 41 , the mold 42 is provided with a circular steam chamber 43 near the inner surface of the mandrel frame body, and an external pressure chamber 44 is formed between the outer jacket 1 and the mold 42 . A row of outer locking screw rods 51 is arranged on the base plate on the outer side of the jacket 1 , and perforations are arranged at corresponding positions on the upper cover plate 2 , and the upper cover plate 2 is flexibly connected by locking screw rods 51 and locking nuts 52 . A row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com