Method for preparing alumina-base eutectic ceramics in laser surface atmosphere heating furnace

A eutectic ceramic and heating furnace technology, applied in the field of laser rapid prototyping of high-performance materials, can solve the problems of material cracking, materials prone to cracks and pores, etc., and achieve the effects of improving compactness, reducing thermal stress, and reducing crack disappearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

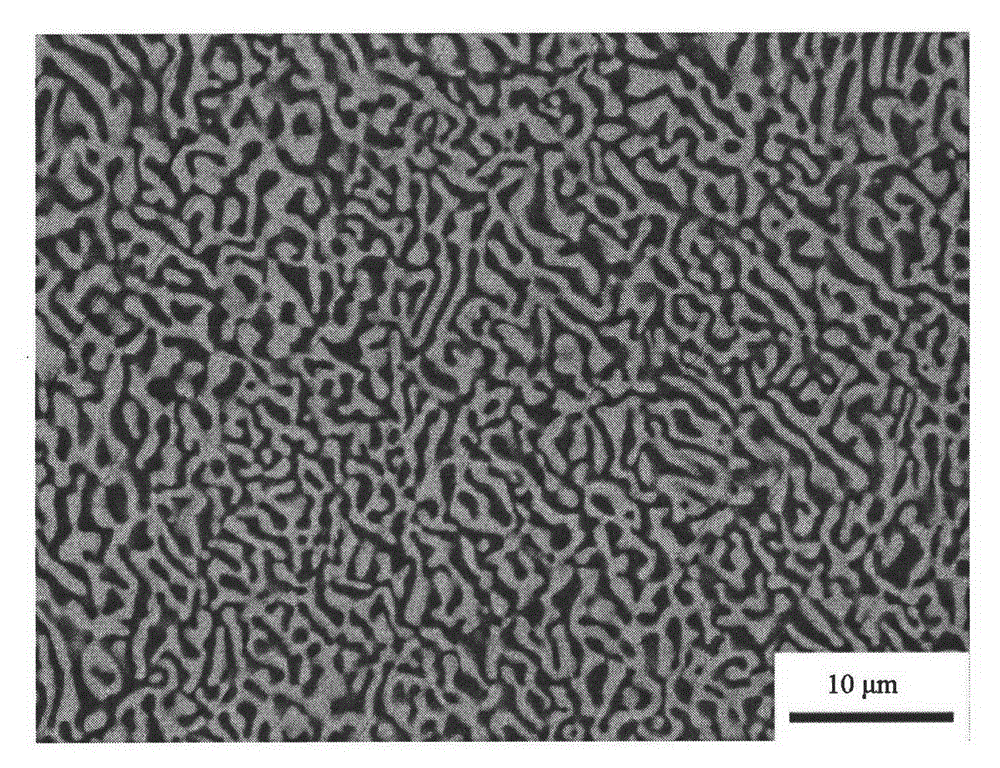

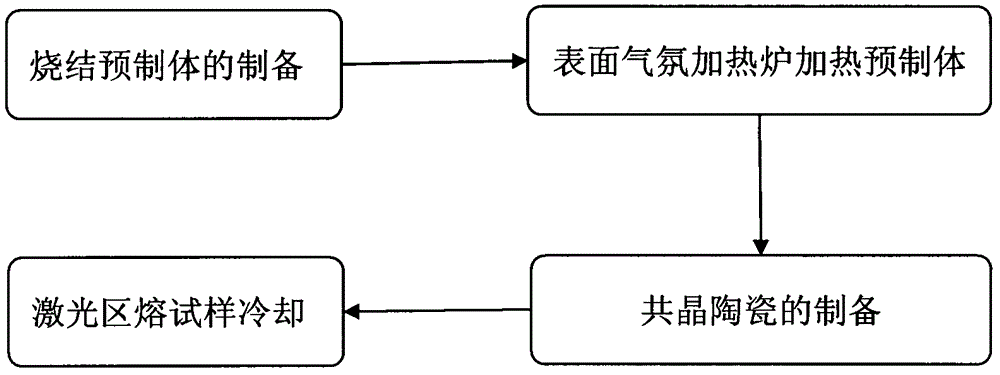

[0022] This embodiment is a method for preparing eutectic ceramics in a laser surface atmosphere heating furnace. In this example, a laser surface atmosphere heating furnace is used to prepare Al 2 o 3 / YAG eutectic ceramics, the specific process includes the following steps:

[0023] Step 1, preparation of sintered preform. with high purity Al 2 o 3 , Y 2 o 3 Powder as raw material, according to eutectic mole percentage Al 2 o 3 : Y 2 o 3 =81:19 for preparation, adding 10% PVA binder of the total amount of raw materials. Put the configured powder in PMQW type omnidirectional planetary ball mill and mix for 4h. The speed of the ball mill is 100r / min. The mixed powder is placed in a mold, and pressed into a plate-shaped sample of 70 mm × 9 mm × 6 mm by a press. The pressing pressure is 25 MPa. The obtained sample was placed in a sintering furnace and sintered for 4 hours at a temperature of 1500° C. to increase the strength of the sample so as to obtain a denser s...

Embodiment 2

[0029] This embodiment is a method for preparing eutectic ceramics in a laser surface atmosphere heating furnace. This example uses a surface atmosphere heating furnace to prepare Al 2 o 3 / YAG / YSZ ternary eutectic ceramics, the specific process includes the following steps:

[0030] Step 1, preparation of sintered preform. with high purity Al 2 o 3 , Y 2 o 3 with ZrO 2 Powder as raw material, according to eutectic mole percentage Al 2 o 3 : Y 2 o 3 : ZrO 2 =65.8: 15.6: 18.6 is prepared, and the PVA binding agent that adds raw material total amount 8%. Put the configured powder in PMQW type omnidirectional planetary ball mill and mix for 4 hours. The speed of the ball mill is 100r / min. The mixed powder is placed in a mold, and pressed into a plate-shaped sample of 70 mm × 9 mm × 3 mm by a press. The pressing pressure is 20 MPa. The obtained sample was placed in a sintering furnace and sintered for 3 hours at a sintering temperature of 1400° C. to increase the s...

Embodiment 3

[0036] This embodiment is a method for preparing eutectic ceramics in a laser surface atmosphere heating furnace. This example uses a surface atmosphere heating furnace to prepare Al 2 o 3 / EAG eutectic ceramics, the specific process includes the following steps:

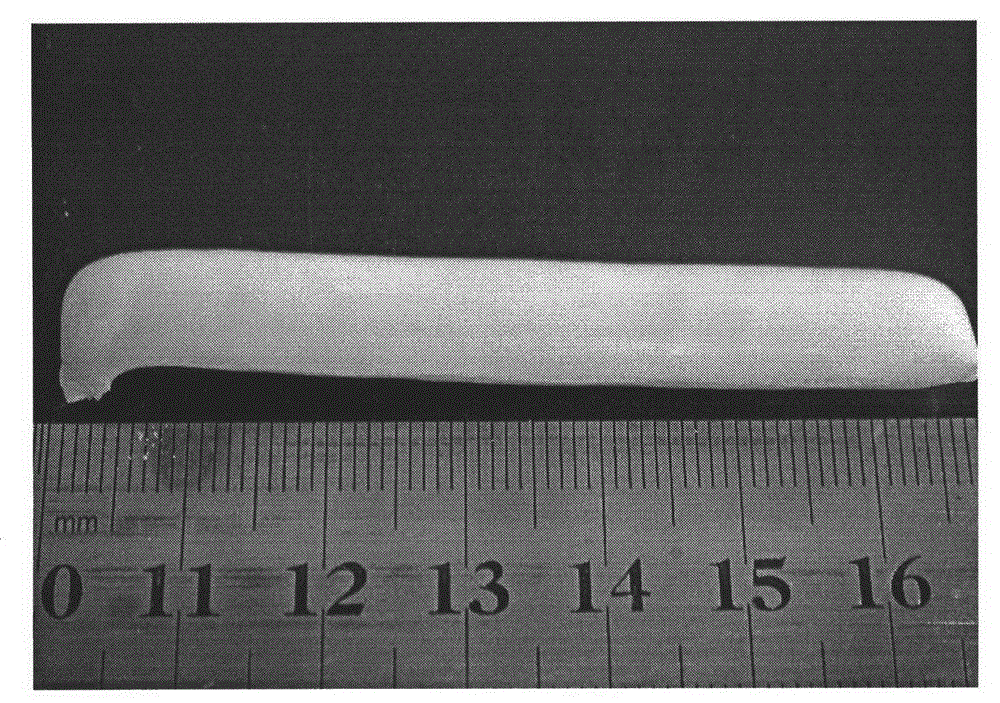

[0037] Step 1, preparation of sintered preform. with high purity Al 2 o 3 、Er 2 o 3 Powder as raw material, according to eutectic mole percentage Al 2 o 3 :Er 2 o 3 =81:19 for preparation, adding 6% PVA binder of the total amount of raw materials. Put the configured powder in PMQW type omnidirectional planetary ball mill and mix for 4h. The speed of the ball mill is 100r / min. The mixed powder is placed in a mold and pressed into a Φ6mm×70mm rod-shaped sample by a press. The pressing pressure is 30MPa. The obtained sample was placed in a sintering furnace and sintered for 2 hours at a sintering temperature of 1200° C. to increase the strength of the sample, thereby obtaining a denser sintered preform. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com