Method for manufacturing plastic pipe flange connectors by pressing and sintering

A flange joint and plastic pipe technology, applied in the field of plastic processing, can solve problems such as uneven heating, accelerated nozzle wear, and low flange strength, and achieve the effects of convenient installation and use, guaranteed butt joint accuracy, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

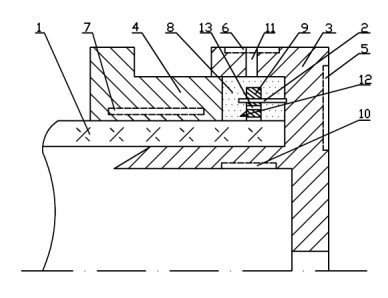

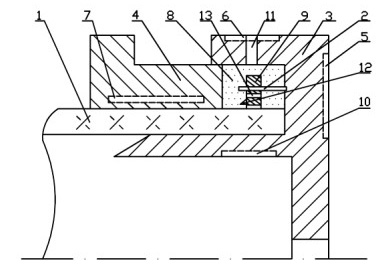

[0016] The present invention is described in detail as follows in conjunction with accompanying drawing:

[0017] This press-sintering method is used to make plastic pipe flange joints. A mold assembly is installed at the end of the plastic pipe, and resin materials of the same material as the plastic pipe are added to the mold cavity formed by the mold assembly, and then pressurized at both ends of the mold. Form the flange preform, and turn on the temperature-controllable heating device at the same time to fully melt the added material, pressurize and keep it for a certain period of time, cut off the heating power supply, and disassemble the mold after cooling to form a flange.

[0018] exist figure 1 Among them, the mold assembly is composed of bottom mold 3, sliding mold 4 and heaters 5, 6, 7, 10. The bottom mold 3 is two concentric cylinders with different sizes of the inner core and the jacket, the inner core is 2° guide taper, the outer diameter of the inner core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com