Polypropylene/fiberglass composite material and preparation method thereof

A glass fiber and composite material technology, which is used in the preparation of polypropylene/glass fiber composite materials and the field of polypropylene/glass fiber composite materials, can solve the problem of poor interfacial bonding strength, low hardness, stiffness and notched impact strength, polypropylene Limited performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

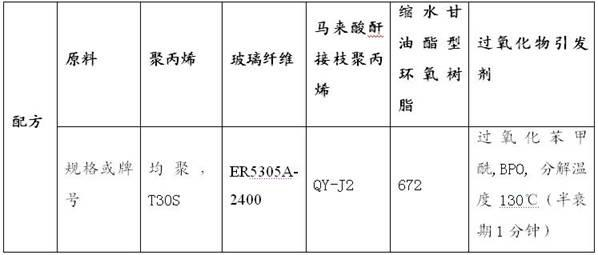

[0023] A preparation method of polypropylene / glass fiber composite material, comprising the steps of:

[0024] (1) Weigh polypropylene, maleic anhydride grafted polypropylene, and peroxide initiator according to the ratio in Table 1-1 and mix them evenly. At a temperature of 160-230°C, add them to the upstream feeding port of the screw extruder for mixing ;

[0025] (2) Synchronously coat the surface of the glass fiber with epoxy resin, weigh the glass fiber before and after coating, calculate the difference between the two to calculate the addition of 2 parts of epoxy resin, and introduce it into the downstream glass fiber inlet of the screw extruder , the shearing action of the screw extruder makes the glass fiber cut into about 0.2-0.5 mm and evenly dispersed in the matrix material;

[0026] (3) Polypropylene / glass fiber composite material can be obtained through extrusion and granulation.

[0027] The material was injection molded into a sample strip, and the performance...

Embodiment 2

[0033] A preparation method of polypropylene / glass fiber composite material, comprising the steps of:

[0034] (1) Weigh the polypropylene, maleic anhydride grafted polypropylene, and peroxide initiator according to the ratio in Table 2-1 and mix them evenly. At a temperature of 160-230°C, add them to the upstream feeding port of the screw extruder for mixing ;

[0035] (2) Synchronously carry out epoxy resin surface coating treatment on the glass fiber, weigh the glass fiber before and after coating, calculate the amount of epoxy resin added by 0.5 parts according to the difference between the two, and introduce it into the downstream glass fiber inlet of the screw extruder , the shearing action of the screw extruder makes the glass fiber cut into about 0.2-0.5 mm and evenly dispersed in the matrix material;

[0036] (3) Polypropylene / glass fiber composite material can be obtained through extrusion and granulation.

[0037] Take the material and inject it into a sample stri...

Embodiment 3

[0045] A preparation method of polypropylene / glass fiber composite material, comprising the steps of:

[0046] (1) Weigh the polypropylene, maleic anhydride grafted polypropylene, and peroxide initiator according to the ratio in Table 3-1 and mix them evenly. At a temperature of 160-210°C, add them to the upstream feeding port of the screw extruder for mixing ;

[0047] (2) Synchronously carry out epoxy resin surface coating treatment on the glass fiber, weigh the glass fiber before and after coating, calculate the amount of epoxy resin added by 1.1 parts according to the difference between the two, and introduce it into the downstream glass fiber inlet of the screw extruder , the shearing action of the screw extruder makes the glass fiber cut into about 0.2-0.5 mm and evenly dispersed in the matrix material;

[0048] (3) Polypropylene / glass fiber composite material can be obtained through extrusion and granulation.

[0049] Take the material and injection mold it into a sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com