Alloy powder filled tungsten argon arc welding method for aluminum alloy

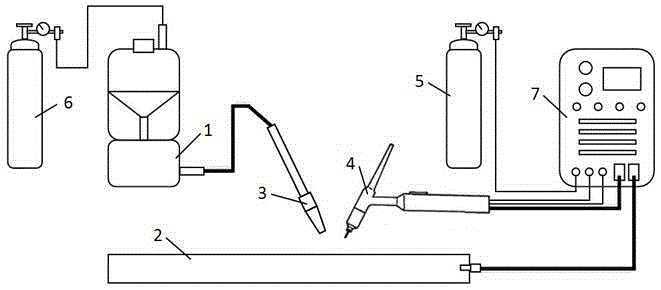

A technology of argon tungsten arc welding and alloy powder, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of low welding speed and deposition efficiency, high requirements for wire feeding accuracy, and low arc power density. , to achieve high deposition efficiency, lower assembly precision requirements, and large welding penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

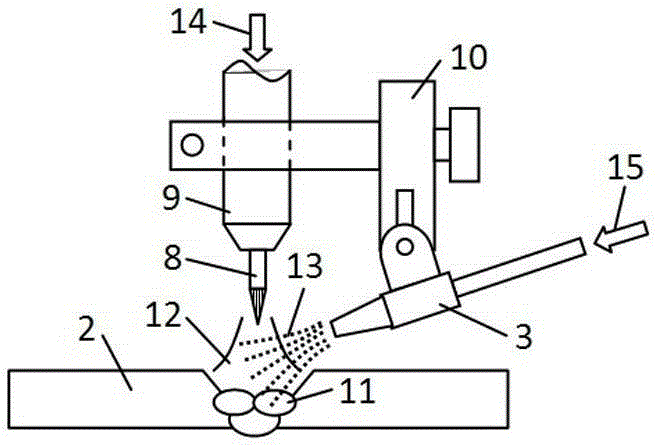

[0034] Embodiment 1: as image 3 As shown, the aluminum alloy workpiece 2 to be welded is the butt joint of two flat plate structures with a thickness of 6 mm. The workpiece 2 has a 30° V-shaped groove, and the height of the blunt edge is 2 mm. The two workpieces 2 are clamped by the fixture without leaving any assembly gap. Set the welding current to 120A, the welding speed to 12m / h, the flow rate of shielding gas 14 to 7L / min, the flow rate of powder feeding working gas 15 to 4L / min, the amount of alloy powder feeding to 150g / min, and the diameter of tungsten electrode 8 to be 2.4 mm. Alloy powder material consists of 6%Cr by weight 2 o 3 Powder, 4%TiO 2 powder and the balance of Al powder, the alloy powder material is dried and placed in the powder feeding mechanism 1, and the alignment between the tungsten electrode 8 and the powder feeding nozzle 3 is corrected so that the extension line of the tungsten electrode 8 and the powder feeding nozzle 3 are sprayed along Th...

Embodiment 2

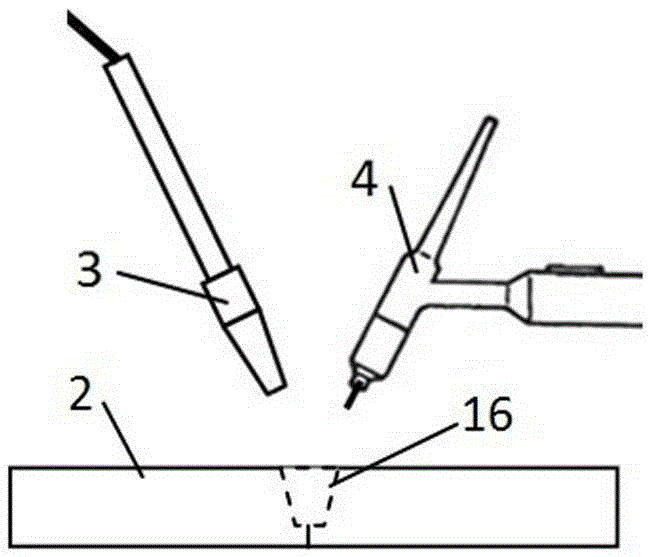

[0035] Embodiment 2: as Figure 4 As shown, the aluminum alloy workpiece 2 to be welded is the butt joint of two flat plate structures with a thickness of 3mm. The workpiece 2 is not beveled, and the two workpieces 2 are clamped by a fixture, and the assembly gap is 1mm. Alloy powder material consists of 6%Cr by weight 2 o 3 Powder, 4%TiO 2 Al powder and the balance of Al powder, the alloy powder material is dried, mixed thoroughly with acetone solution, and evenly brushed and filled in the reserved gap of the workpiece 2 to be welded, and a certain layer of alloy powder is formed on the surface of the part to be welded. The acetone solution in the preset alloy powder 17 is completely volatilized. Set the welding current to 120A, the welding speed to 10m / h, the flow rate of the shielding gas 14 to 7L / min, and the diameter of the tungsten electrode 8 to 2.4mm. Turn on the argon tungsten arc welding torch 4 to supply gas in advance to protect the area to be welded, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com