Environment-friendly flame-retardant cable material and preparation method thereof

A flame-retardant cable material and environmental protection technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of reduced elongation at break, cables that do not meet the requirements, and large additions, so as to reduce the embrittlement point and improve mechanical properties , Improve the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

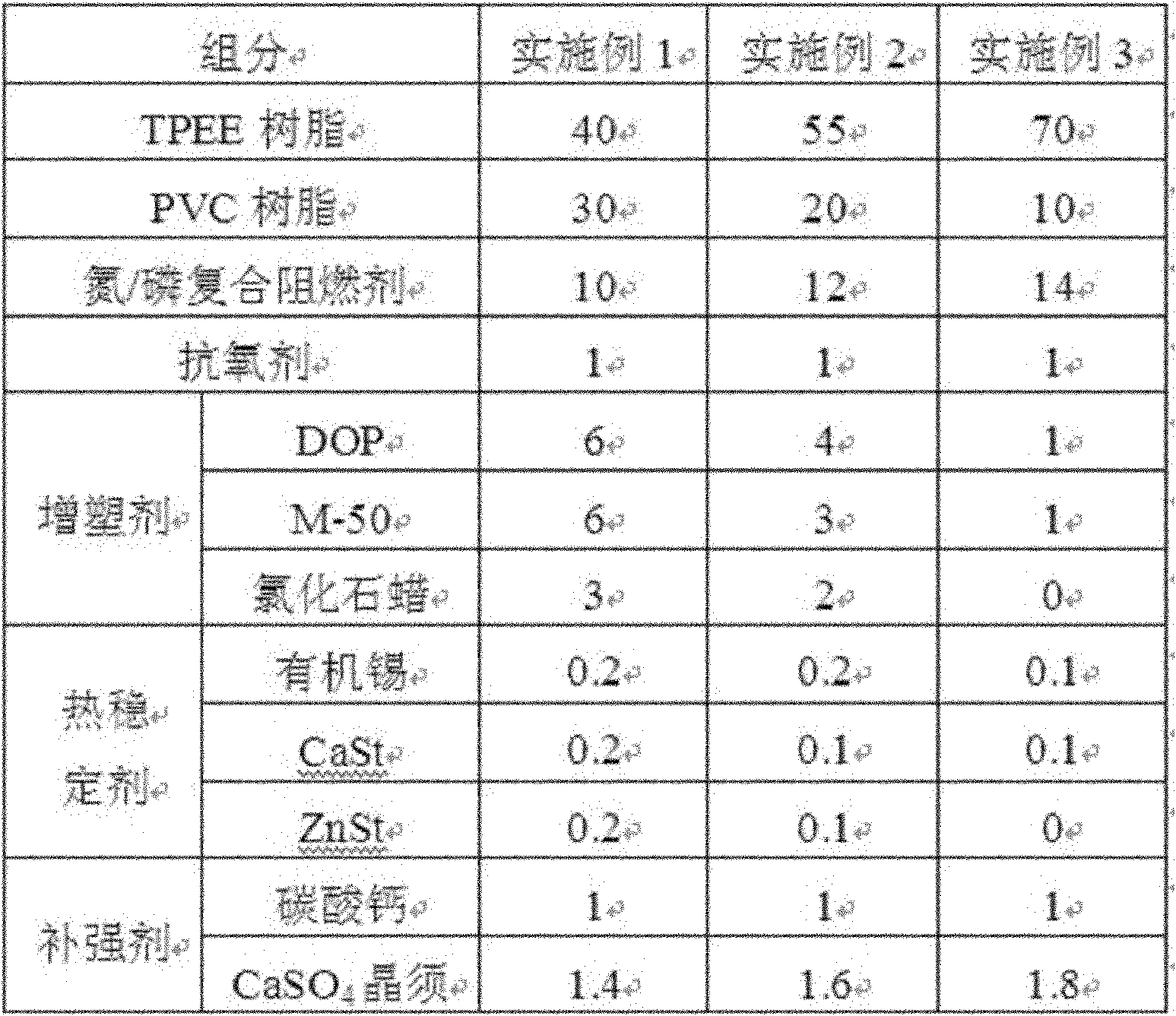

Examples

Embodiment 4

[0037] An environmentally friendly flame-retardant cable material, comprising the following components and parts by weight:

[0038] TPEE resin 40; PVC resin 30; nitrogen / phosphorus composite flame retardant 14, wherein nitrogen-based flame retardant is melamine, phosphorus-based flame retardant is polyphosphate amine, nitrogen / phosphorus ratio is 5 / 4; antioxidant 1010 2; plasticizer chlorinated paraffin 15; heat stabilizer organotin 0.6; reinforcing agent calcium carbonate 3.

[0039] Weigh the PVC resin, plasticizer, heat stabilizer and antioxidant according to the proportion and add them to the high-speed mixer for mixing. After the mixing is completed, add the mixture to the twin-screw extruder to make master batches for use. The processing temperature is 180-195℃; then the masterbatch is evenly mixed with TPEE resin, nitrogen / phosphorus composite flame retardant and reinforcing agent, and then added to the extruder to melt, extrude, and pelletize. The processing temperatu...

Embodiment 5

[0041] An environmentally friendly flame-retardant cable material, comprising the following components and parts by weight:

[0042] TPEE resin 70; PVC resin 10; nitrogen / phosphorus composite flame retardant 10, wherein the nitrogen-based flame retardant is melamine phosphate, the phosphorus-based flame retardant is red phosphorus, and the ratio of nitrogen / phosphorus is 4 / 1.4; antioxidant Agent 1098 0.5; plasticizer DOP 2; heat stabilizer CaSt 0.2; reinforcing agent CaSO4 whisker 2.

[0043] Weigh the PVC resin, plasticizer, heat stabilizer and antioxidant according to the proportion and add them to the high-speed mixer for mixing. After the mixing is completed, add the mixture to the twin-screw extruder to make master batches for use. The processing temperature is 180-195℃; then the masterbatch is evenly mixed with TPEE resin, nitrogen / phosphorus composite flame retardant and reinforcing agent, and then added to the extruder to melt, extrude, and pelletize. The processing te...

Embodiment 6

[0045] An environmentally friendly flame-retardant cable material, comprising the following components and parts by weight:

[0046] TPEE resin 62; PVC resin 25; nitrogen / phosphorus composite flame retardant 13, wherein the nitrogen-based flame retardant is a mixture of melamine and melamine phosphate in a weight ratio of 1:1, and the phosphorus-based flame retardant is phosphoramine and trimethylbenzene phosphate A mixture of ester weight ratio of 1:2, nitrogen / phosphorus ratio of 5 / 1; antioxidant 1076 1, antioxidant 168 0.5; plasticizer DOP 8, plasticizer M-50 4; heat stabilizer CaSt 0.2, heat stabilizer ZnSt 0.3; reinforcing agent calcium carbonate 1, CaSO4 whisker 1.5.

[0047] Weigh the PVC resin, plasticizer, heat stabilizer and antioxidant according to the proportion and add them to the high-speed mixer for mixing. After the mixing is completed, add the mixture to the twin-screw extruder to make master batches for use. The processing temperature is 180-195℃; then the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com