Preparation method of hydrogen storage material nano catalysis system

A hydrogen storage material and nano-catalysis technology, applied in the field of hydrogen storage materials, can solve the problems of low dispersion distribution, pollution of hydrogen sources, and difficulty in obtaining catalytic phase composite structure, so as to optimize structure and performance, ensure uniform phase composite, and broad The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Adopt NaH / Al powder mixture as starting material, apply the method and device of the present invention to prepare Ti-NaAlH 4 Composite catalytic system and post-milling treatment.

[0043] The raw materials used are: NaH (purity 95wt%, ~100 mesh), Al (purity 99.9wt%, ~325 mesh), high-purity Ti target (purity>99.99wt%).

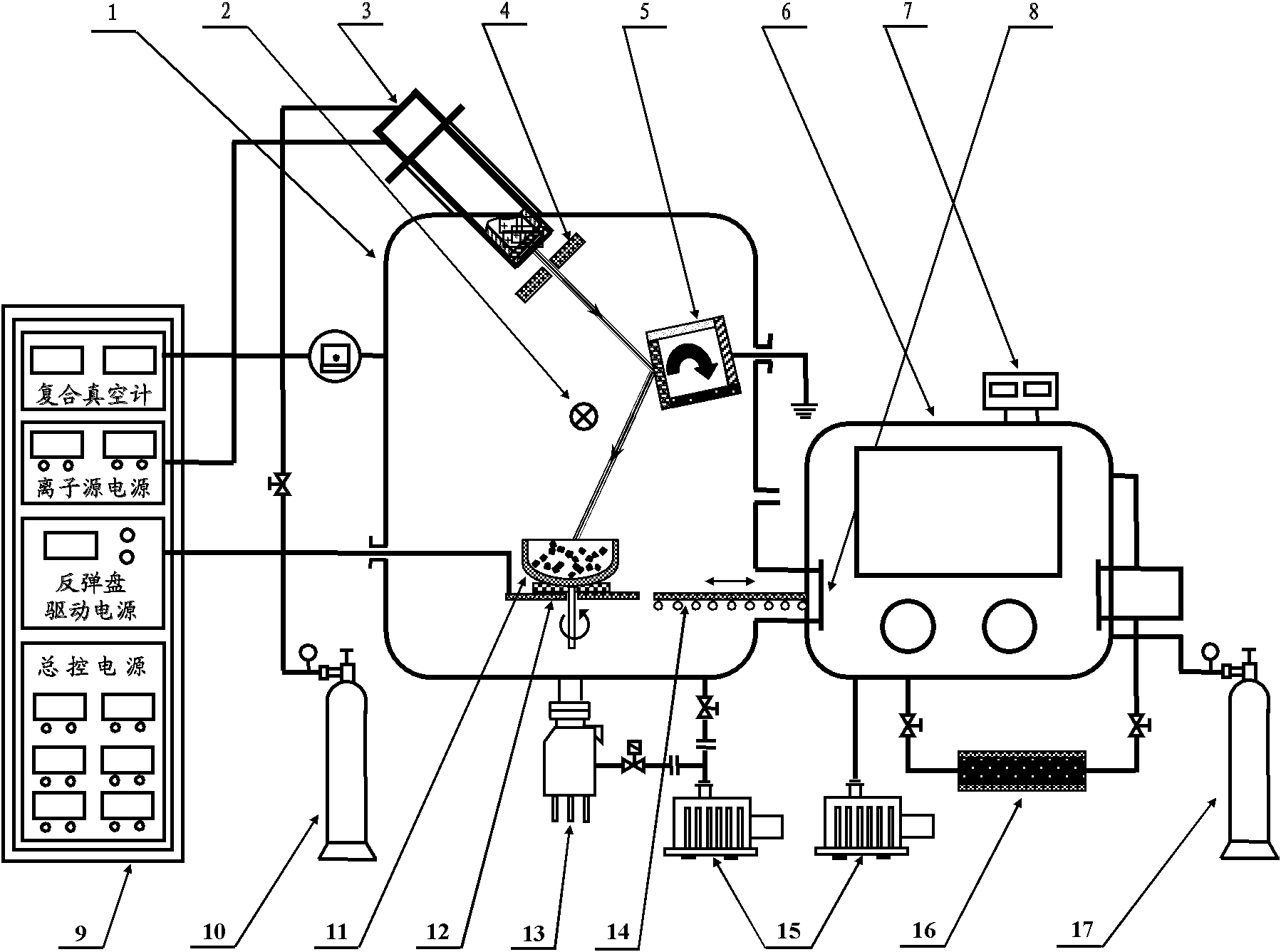

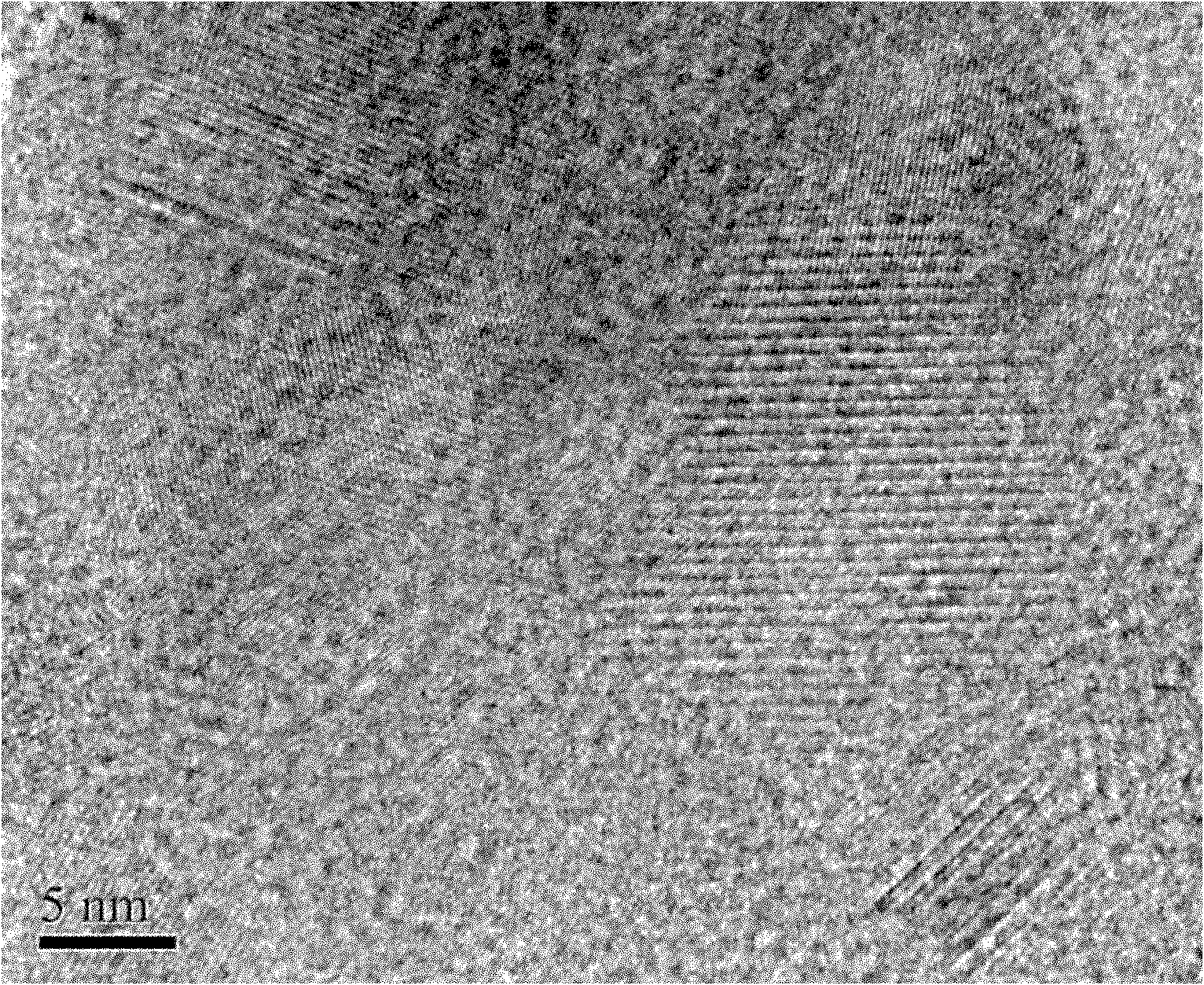

[0044] Sample preparation process: in an argon atmosphere glove box, a NaH / Al powder mixture (molar ratio of 1:1) sample (about 0.5 g) was placed in a rebound pan, and the valve between the glove box and the vacuum chamber was opened. Seal the hatch, transfer the rebound disk to the vacuum chamber through the sample transfer mechanism and fix it to the rebound disk drive device. After closing the airtight hatch, turn on the mechanical pump and the molecular pump in sequence to evacuate the vacuum chamber to 5×10 -4 Pa, fill the vacuum chamber with high-purity argon (volume purity ≥99.9999%) to about 5×10 -2 Pa, then turn on the sputter ion source. A...

Embodiment 2

[0050] The difference from Example 1 is that using NaAlH 4 As a raw material, the method and device of the present invention are used to prepare Ti-NaAlH 4 Composite catalytic system and post-milling treatment.

[0051] The raw material used is: NaAlH 4 (purity 90wt%, ~100 mesh), high-purity Ti target (purity>99.99wt%).

[0052]The sample preparation process is the same as in Example 1. During the ion sputtering process, the discharge voltage was set to 80V, the filament current was 6A, the accelerating voltage was 200V, the beam current voltage was 900V, and the filament current was adjusted to a beam current of 20mA. The sputtering time was 0.5 hours. The post-milling treatment was carried out under the atmosphere of high-purity Ar (volume purity 99.999%), the mass ratio of ball to material was 40:1, and the ball milling time was 2 hours. In this example Ti-NaAlH 4 In the composite material, the molar percentage of Ti is about 0.5%, and the rest is NaAlH 4 .

[0053]...

Embodiment 3

[0055] The difference from Example 1 is that the method and device of the present invention are used to prepare Fe-NaAlH 4 Composite catalytic system and post-milling treatment.

[0056] The raw material used is: NaAlH 4 (purity 90wt%, ~100 mesh), high-purity Fe target (purity>99.9wt%).

[0057] The sample preparation process is the same as in Example 1. During the ion sputtering process, set the discharge voltage to 70V, the filament current to 5A, the acceleration voltage to 180V, the beam current voltage to 800V, and adjust the filament current to a beam current of 18mA. The sputtering time was 0.5 hours. The post-milling treatment is carried out under the atmosphere of high-purity Ar (volume purity 99.999%), the mass ratio of ball to material is 40:1; the ball milling time is 5 hours. This embodiment Fe-NaAlH 4 In the composite material, the molar percentage of Fe is about 2%, and the rest is NaAlH 4 .

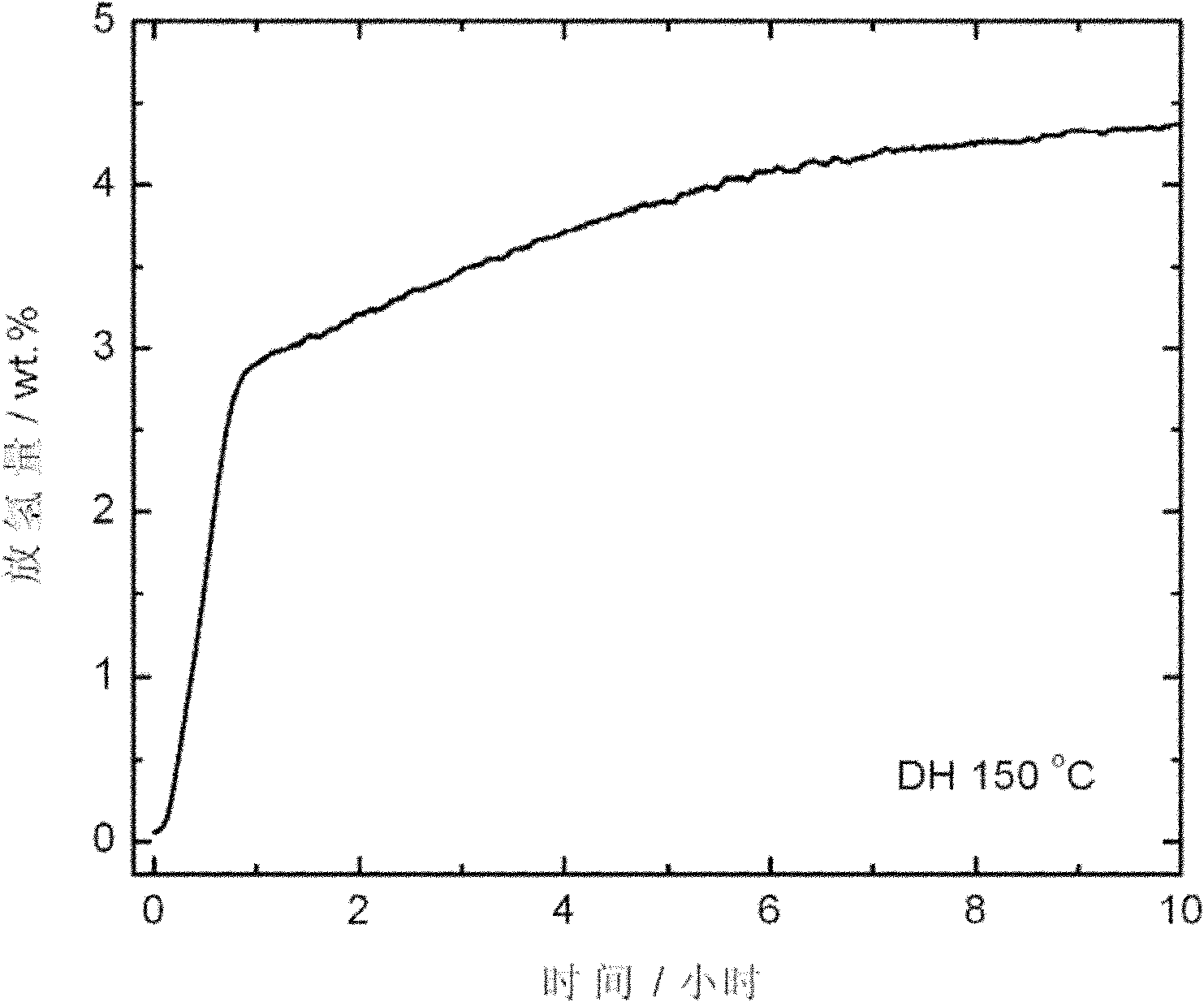

[0058] Figure 6 The prepared Fe-NaAlH 4 Hydrogen desorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com