Single LED (light-emitting diode) light source radiating seat and LED lamp

A technology of LED light source and heat sink, which is applied in the field of single LED light source heat sink and LED lamp, can solve the problems affecting the heat dissipation performance of LED light source, and achieve the effect of enhanced heat dissipation performance and high heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of a single LED light source heat sink and LED lamp will be further described in detail below mainly in conjunction with the accompanying drawings and specific embodiments. The LED lamp provided by the present invention may include multiple LED light source heat sinks and multiple LED light sources. like figure 1 , figure 2 As shown, one of the LED light source heat sinks 100 includes: a substrate 120 for fixing the LED light source 110 , a heat dissipation block 130 connected to the substrate 120 , and a heat dissipation plate 140 connected to the heat dissipation block 130 .

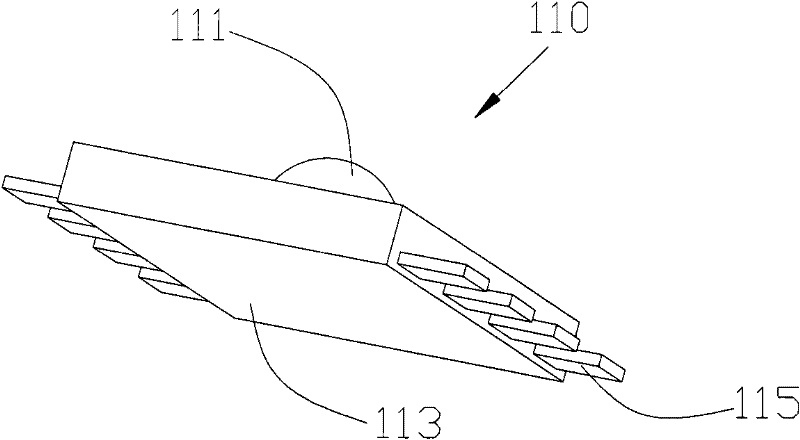

[0024] like image 3 As shown, the LED light source 110 of this embodiment includes a light-emitting chip 111, a heat dissipation pad 113 for fixing the light-emitting chip 111, and circuit leads 115 electrically connected to the light-emitting chip 111 drawn from both sides of the heat dissipation pad 113. The circuit leads are fixed on the On the substrate of the LED light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com