Method for preparing tungsten carbide-titanium dioxide composite catalyst

A composite catalyst, titanium dioxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation and other directions, can solve the problems of unfavorable composite reaction of titanium dioxide and ammonium metatungstate, low utilization rate of raw materials, and high production costs , to achieve the effect of improving platinum-like catalytic activity, reducing production cost, and improving electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

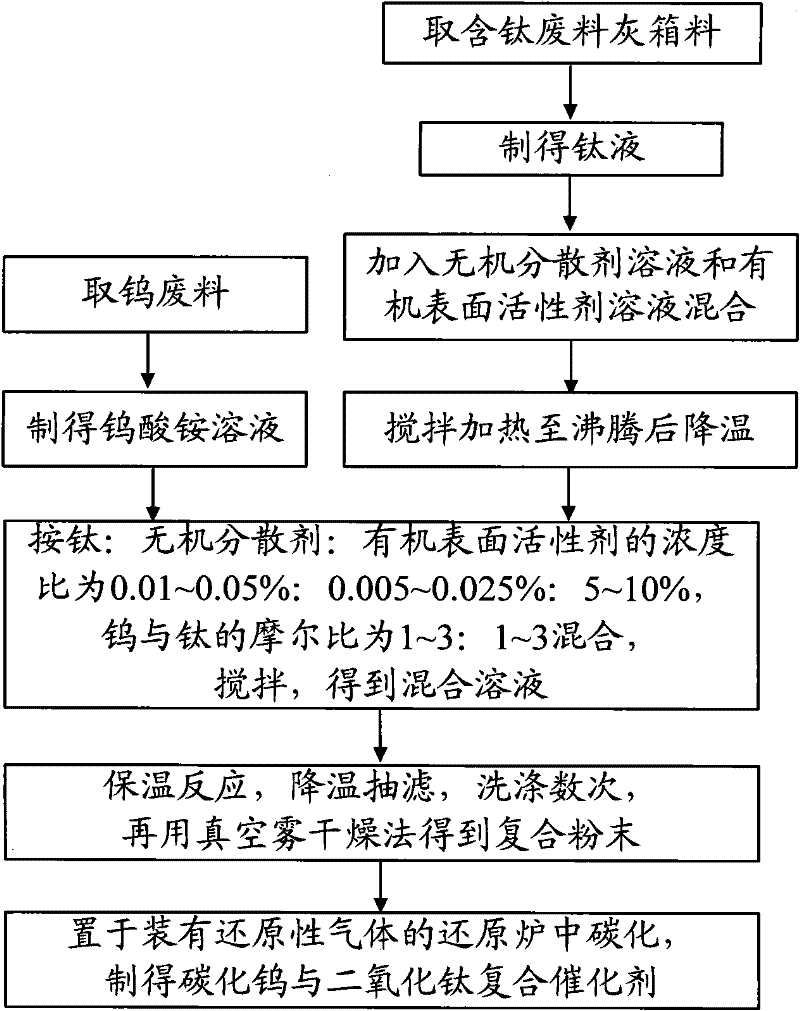

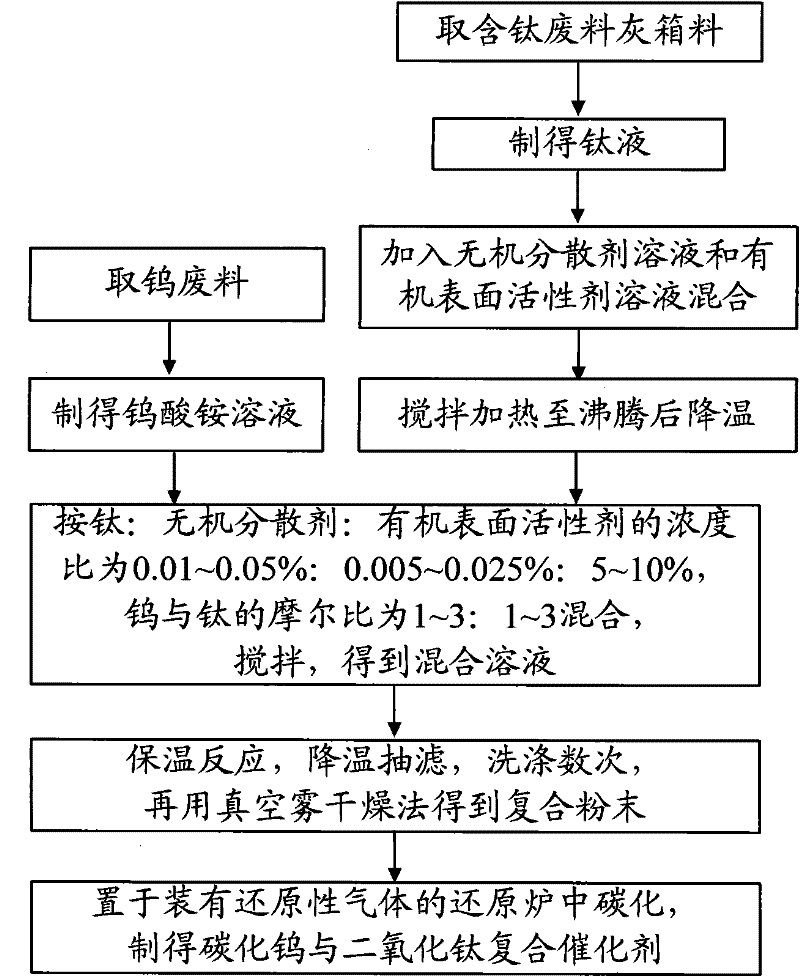

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing tungsten carbide and titanium dioxide composite catalyst, comprising the following steps:

[0042] (1) Take the waste catalyst containing tungsten (acrylic acid second-stage catalyst and petroleum hydrogenation catalyst RN-1, 3581 catalyst are produced by oxidation of waste propylene), remove water, organic matter and carbon deposits, etc., and control the temperature at 600 ° C. The roasting time is 8 hours, and then it is roasted at 700°C for 8 hours until all the tungsten sulfide is oxidized to tungsten trioxide; the roasted material is cooled and pulverized, and leached with 18.5% ammonia water, the leaching temperature is 78°C, and the leaching time is 8h, until The tungsten trioxide in it is completely dissolved; the leaching solution is kept at 56°C for 10 hours to precipitate impurities such as silicon, phosphorus and iron, and then filtered, and the filtrate is ammonium tungstate solution with a concentration of 30%.

[0043] (2) It is 1:...

Embodiment 2

[0048] A method for preparing tungsten carbide and titanium dioxide composite catalyst, comprising the following steps:

[0049] (1) Take the tungsten leaching slag, remove the water, organic matter and carbon deposits, etc., the temperature is controlled at 650 ° C, the roasting time is 8 hours, and then it is roasted at 750 ° C for 8 hours; the roasted material is cooled and pulverized, and 20% Ammonia water leaching, the leaching temperature is 90°C, and the leaching time is 7.5h, until the tungsten trioxide in it is completely dissolved; the leaching solution is kept at 65°C for 10h, so that impurities such as silicon, phosphorus, and iron in it are precipitated, and then filtered. The liquid is ammonium tungstate solution.

[0050] (2) It is 1: 1 to add the hydrochloric acid that mass fraction is 25% to make suspension with titanium-containing waste material ash box material by solid-liquid ratio, add solid ammonium sulfate and mass fraction is the concentrated sulfuric a...

Embodiment 3

[0055] A method for preparing tungsten carbide and titanium dioxide composite catalyst, comprising the following steps:

[0056] (1) Take the waste catalyst containing tungsten (acrylic acid second-stage catalyst and petroleum hydrogenation catalyst RN-1, 3581 catalyst are produced by oxidation of waste propylene), remove water, organic matter and carbon deposits, etc., and control the temperature at 630 ° C. The roasting time is 8 hours, and then it is roasted at 720°C for 8 hours until all the tungsten sulfide is oxidized to tungsten trioxide; the roasted material is cooled and pulverized, and leached with 19% ammonia water, the leaching temperature is 85°C, and the leaching time is 8h, until The tungsten trioxide in it is completely dissolved; the leaching solution is kept at 60°C for 10 hours to precipitate impurities such as silicon, phosphorus and iron, and then filtered, and the filtrate is ammonium tungstate solution.

[0057] (2) It is 1: 1 to add the hydrochloric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com