Preparation method for polyester fiber with compound ultraviolet ray resisting, aging resisting, moisture absorbing and quick drying functions

An anti-ultraviolet, moisture-absorbing and quick-drying technology, applied in the direction of one-component polyester rayon, can solve the problems of poor anti-ultraviolet performance, easy to generate static electricity, need to be improved, etc., achieve good dispersion effect, reduce volatilization, and reduce residence time effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

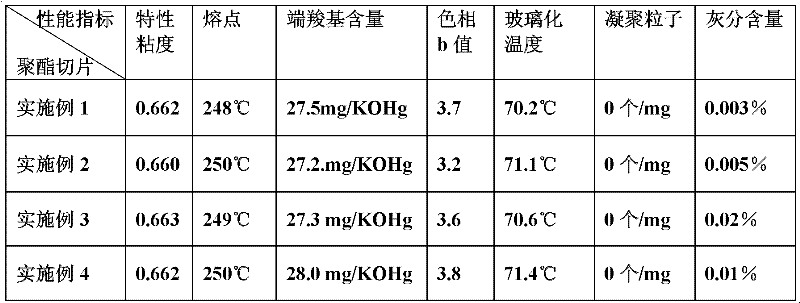

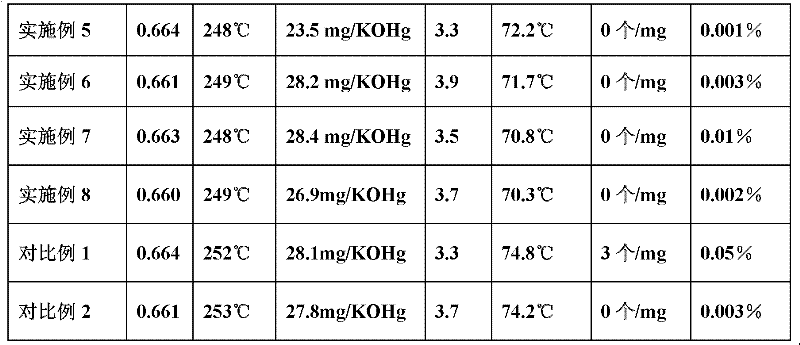

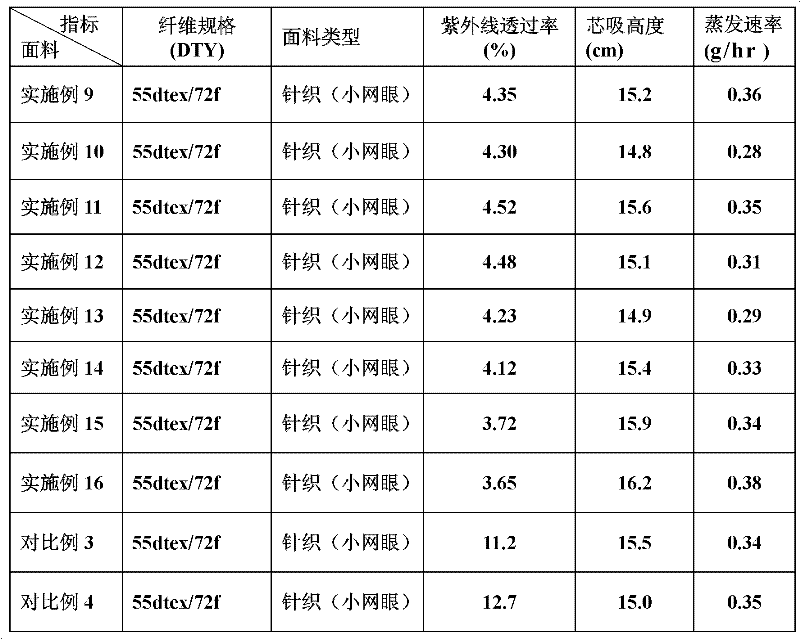

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing an anti-ultraviolet, anti-aging polyester chip, which comprises the following steps:

[0032] (1), Esterification process: Take 18kg of purified terephthalic acid (PTA), 0.45kg of isophthalic acid, 0.05kg of neopentyl glycol, and 7.05kg of ethylene glycol (EG) into a 70-liter esterification reaction kettle , after stirring evenly, start to heat up and pressurize to 0.3Mpa to carry out esterification. The esterification temperature is controlled at 250°C-265°C.

[0033] (2), polymerization reaction process: after esterification is finished, at first add titanium dioxide matting agent, add-on is 1.5% of polyester chip weight, then add polymerization catalyst, and add 1.125g composite light stabilizer (Tinuvin 788 and 119FL mixed in a weight ratio of 1:1), 3.375g of composite antioxidant (Irganox 1076 and Irganox 1010 mixed in a weight ratio of 1:3). After stirring evenly, send it to the pre-polymerization tank to heat up a...

Embodiment 2

[0035] This embodiment provides a method for preparing an anti-ultraviolet, anti-aging polyester chip, which comprises the following steps:

[0036] (1), esterification reaction process: get 18kg purified terephthalic acid (PTA), 0.45kg1,4-cyclohexanedicarboxylic acid, 0.05kg neopentyl glycol, 7.05kg ethylene glycol (EG) and add 70 liters of ester After stirring evenly in the reaction kettle, start to heat up and pressurize to 0.3Mpa to carry out esterification. The esterification temperature is controlled at 250°C to 265°C. After the esterification is completed, return to normal pressure and complete the reaction to obtain polymerized monomers.

[0037] (2), polymerization reaction process: after esterification is finished, at first add titanium dioxide matting agent, add-on is 1.5% of polyester chip weight, then add polymerization catalyst, and add 1.125g composite light stabilizer (Tinuvin 788 and 119FL mixed in a weight ratio of 1:1), 3.375g of composite antioxidant (Irga...

Embodiment 3

[0039] This embodiment provides a method for preparing an anti-ultraviolet, anti-aging polyester chip, which comprises the following steps:

[0040] (1), esterification reaction process: get 18kg purified terephthalic acid (PTA), 0.45kg isophthalic acid, 0.05kg neopentyl glycol, 7.05kg ethylene glycol (EG) add 70 liters of esterification reactors, After stirring evenly, start to raise the temperature and pressurize to 0.3Mpa to carry out esterification. The esterification temperature is controlled at 250°C to 265°C. After the esterification is completed, return to normal pressure and complete the reaction to obtain polymerized monomers.

[0041](2), polymerization reaction process: after esterification is finished, at first add titanium dioxide matting agent, add-on is 1.5% of polyester chip weight, then add polymerization catalyst, and add 1.125g composite light stabilizer (Tinuvin 788 and 119FL mixed in a weight ratio of 1:1), 3.375g of composite antioxidant (Irganox 1076 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com