Preparation method of pseudo-boehmite

A technology of pseudo-boehmite and sodium aluminate, applied in the field of preparation of pseudo-boehmite, can solve problems such as harsh operating conditions, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

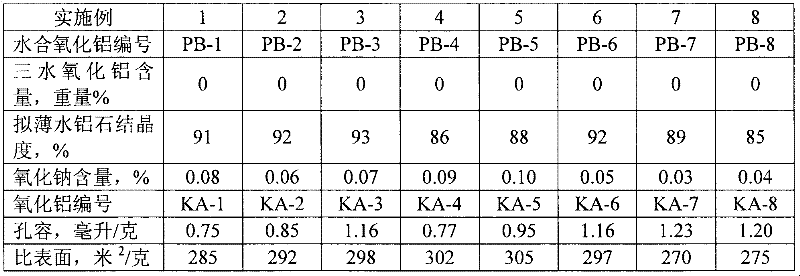

Examples

Embodiment 1

[0042] According to the method provided by the invention, pseudo-boehmite is prepared in batch mode.

[0043] Add 2L of deionized water in advance in an 8-liter gelling tank (with a gas distributor at the bottom), the initial temperature is 30°C, and feed carbon dioxide content of 30% by volume and dinitrogen pentoxide through the gas distributor from the bottom of the gelling tank For a mixed gas with a content of 5% by volume and the balance being air, the flow rate of the mixed gas is adjusted to 5.2 meters 3 / hour, when the pH of the deionized water in the tank is lower than 5.0, add a concentration of 100 grams of Al into the tank through flowmeter metering 2 o 3 / liter of sodium aluminate solution, adjust the flow rate of sodium aluminate solution to maintain the pH value of the system at 6.7. At this time, the flow rate of sodium aluminate is 4L / hour, and the gelation reaction stops after 1 hour of reaction. At this time, the slurry temperature is 45 °C. Transfer th...

Embodiment 2

[0045] According to the method provided by the invention, pseudo-boehmite is prepared in batch mode.

[0046] Add 2L of deionized water in advance in an 8-liter gelling tank (with a gas distributor at the bottom), and the initial temperature is 25 ° C. From the bottom of the gelling tank through the gas distributor, add 25% of carbon dioxide and 18% of sulfur dioxide. %, the balance is a mixture of air, adjust the flow rate of the mixture to 3.2 meters 3 / hour, when the pH of the deionized water in the tank is lower than 5.5, add a concentration of 150 grams of Al into the tank by metering the flow meter 2 o 3 / liter of sodium aluminate solution, adjust the flow rate of sodium aluminate solution to maintain the pH value of the system at 6.8, at this time, the flow rate of sodium aluminate is 3.5L / hour, and stop the gelation reaction after 1.5 hours of reaction, at this time, the slurry temperature is 43 °C . Transfer the slurry to an aging reaction kettle, adjust the pH v...

Embodiment 3

[0048] According to the method provided by the invention, pseudo-boehmite is prepared in batch mode.

[0049] Add 2L of deionized water to an 8-liter gelling tank (with a gas distributor at the bottom), and the initial temperature is 35°C. 15 volume%, the balance is air mixture, adjust the flow rate of the mixed gas to 2.1 meters 3 / hour, when the pH of the deionized water in the tank is lower than 3.0, add a concentration of 200 grams of Al into the tank by metering the flow meter 2 o 3 / liter of sodium aluminate solution, adjust the flow rate of sodium aluminate solution to maintain the pH value of the system at 5.2. At this time, the flow rate of sodium aluminate is 2L / hour, and the gelation reaction stops after 1 hour of reaction. At this time, the slurry temperature is 52 ° C. Transfer the slurry to an aging reaction kettle, adjust the pH value of the slurry to 8.6 with 15% (mass) ammonia solution, raise the temperature to 70° C., and age at a constant temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com