Packaging structure of OLED

A technology of electroluminescent devices and packaging structures, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of device film structure defects, difficult to realize flexible coil production, complex processing technology, etc., and achieve equipment saving Investment cost and floor area, blocking the penetration of water and oxygen into the device, and the effect of low deposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

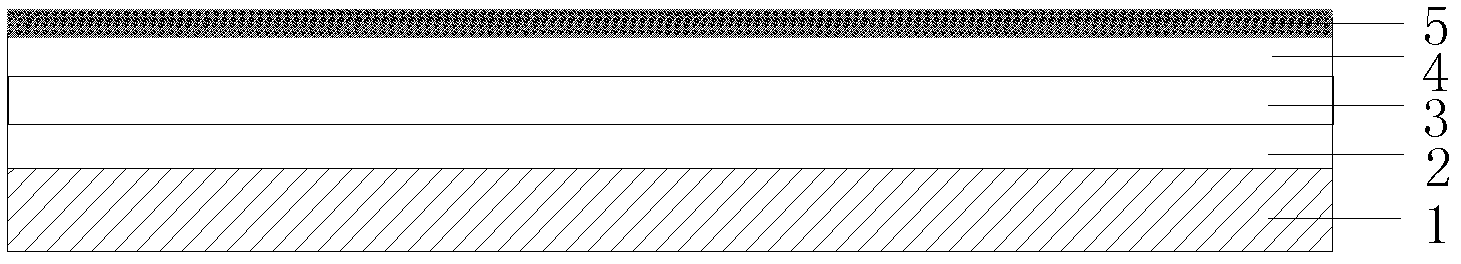

[0025] Such as figure 1 The packaging structure of the organic electroluminescent device shown in the present invention includes a substrate 1 of an electroluminescent device made of glass, and an anode 2, an organic layer 3 and a cathode 4 of the organic electroluminescent device are arranged on one side of the substrate 1. An encapsulation layer 5 is provided on the outside of the cathode 4, and the encapsulation layer 5 is a multi-layer composite film structure in which at least two inorganic insulating materials are alternately deposited by an atomic layer deposition system.

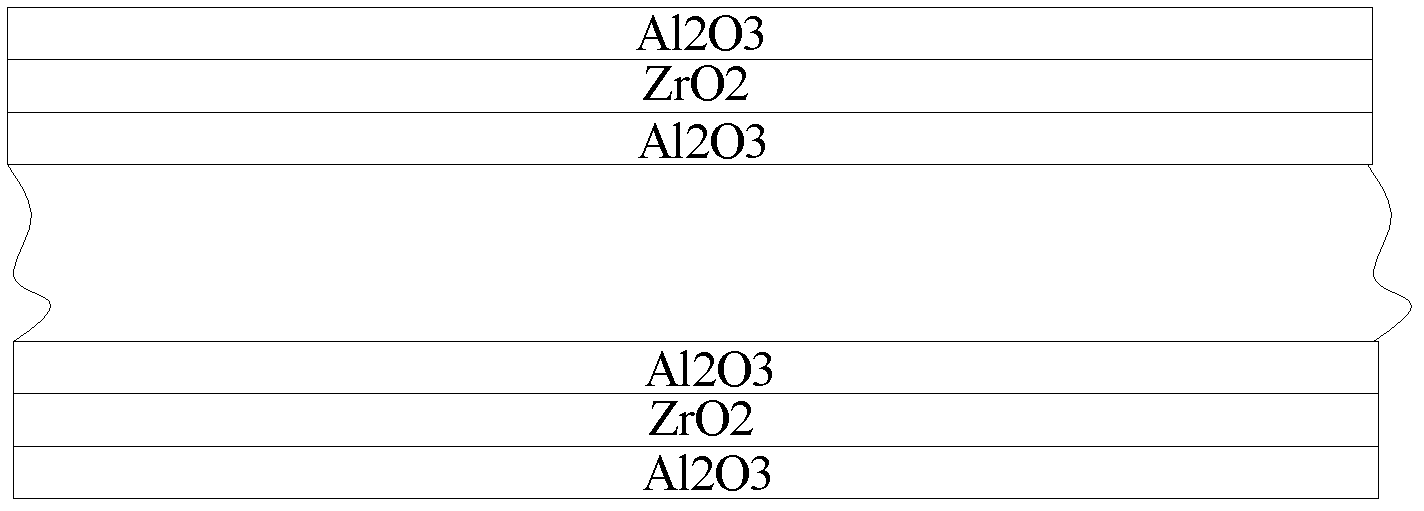

[0026] Such as figure 2 As shown, after the unpackaged organic electroluminescent device is placed in the atomic layer deposition system, the mask plate is aligned to cover the device lead-out electrode, and a high-purity inert gas is introduced. After vacuuming, the cathode of the light-emitting device 4. Deposit Al with a thickness of 2-5nm on the 2 o 3 film layer, and then in the Al 2 o 3 Th...

Embodiment 2

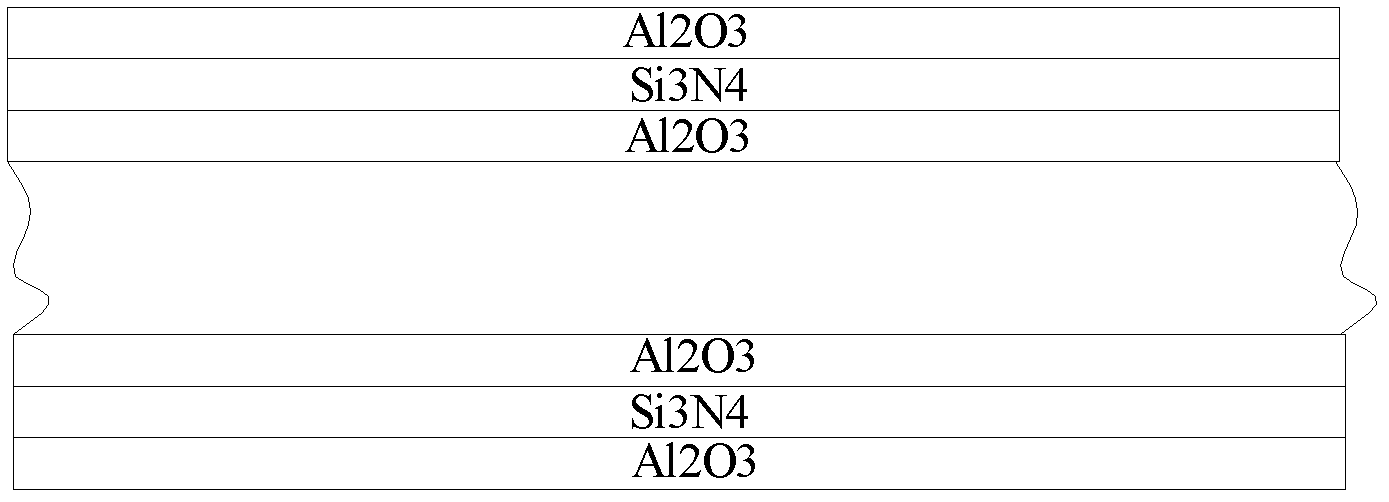

[0028] Such as image 3 As shown, on the basis of Example 1, the difference is to deposit Al with a thickness of 2-5 nm on the cathode 4 of the light-emitting device. 2 o 3 film layer, and then in the Al 2 o 3 The outer layer of the film layer is deposited with a thickness of 2-5nm Si 3 N 4 film layer, repeat the above film deposition steps 20 times (i.e. 20 layers), to obtain an Al with a thickness of 80-200nm 2 o 3 / Si 3 N 4 Membrane encapsulation layer 5.

Embodiment 3

[0030] On the basis of Embodiment 1 or 2, the substrate 1 is made of plastic, and packaging layers 5 are respectively provided on the outside of the cathode 4 and the inside of the substrate 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com