Method for preparing efficient thin-film solar cell light absorption layer

A technology for solar cells and light absorbing layers, which is applied in the manufacturing of circuits, electrical components, and final products, etc., can solve the problems of affecting CIGS preparation, poor preparation uniformity, and high environmental protection costs, and achieves low cost, simple equipment, and low deposition temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

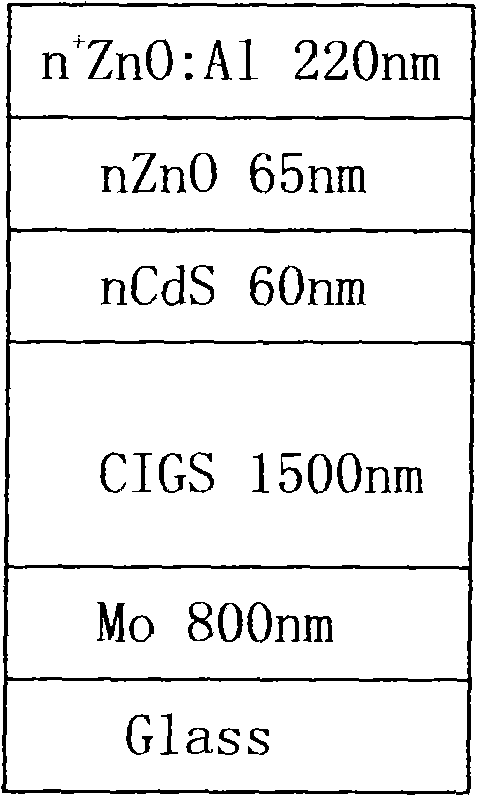

Image

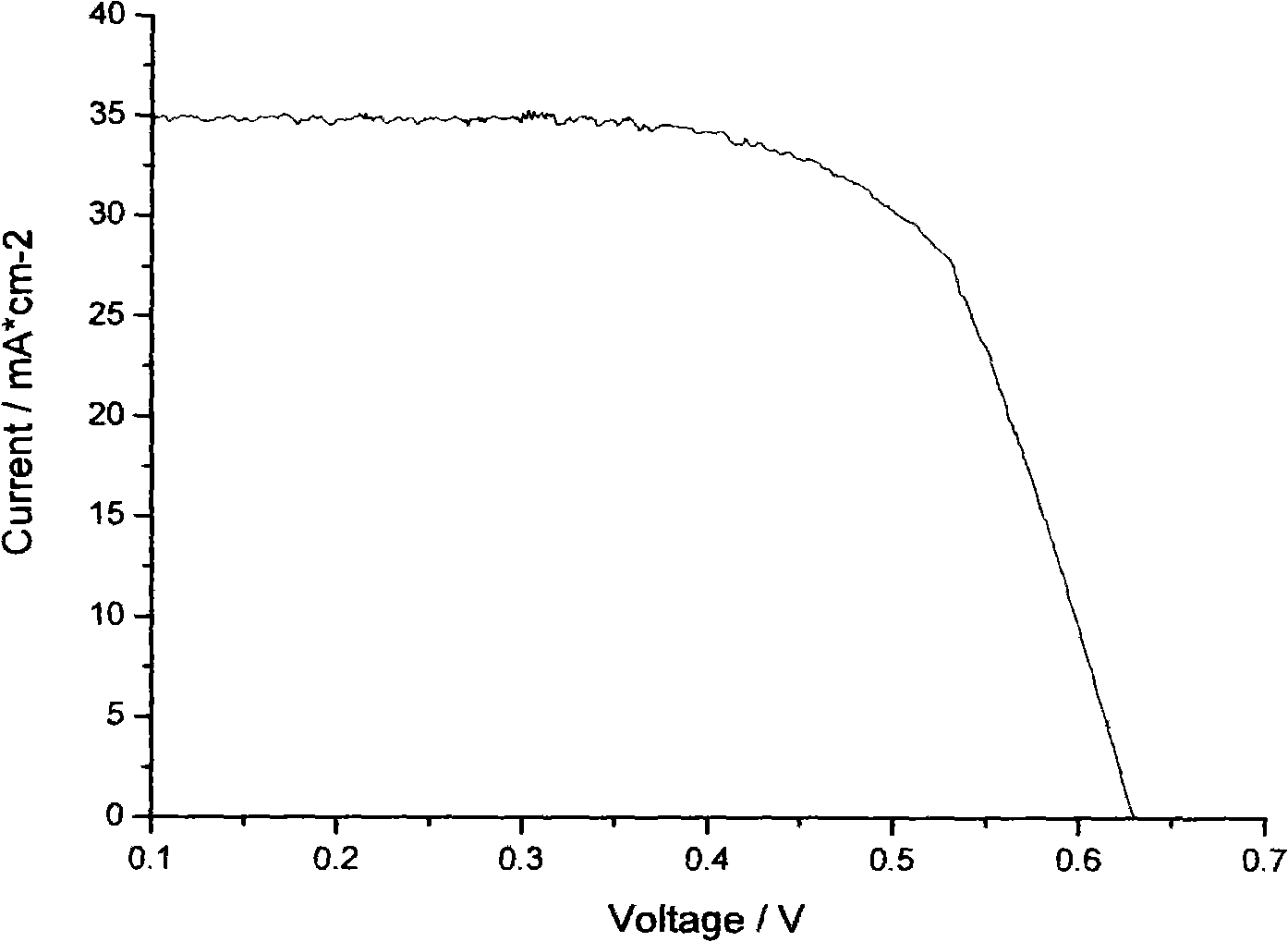

Examples

Embodiment 1

[0021] First, the following solutions were prepared respectively in a nitrogen protective atmosphere:

[0022] Prepare solution A: weigh 1.283g Cu 2 S, 0.512g S was added to 16mL of hydrazine solution, after 10h of stirring reaction, it was allowed to stand still to form a clear yellow solution A;

[0023] Preparation of colorless solution B: Dissolve 2.486 g of In 2 Se 3 Prepared by dissolving 0.421g Se in 16mL of hydrazine solution;

[0024] Prepare solution C: Dissolve 1.264g of Se in 8mL of hydrazine and react;

[0025] Preparation of solution D: Continue to weigh 0.561g Ga and 1.264g Se into 16mL of hydrazine solution to obtain colorless solution D.

[0026] Then, pipette 2.0mL of solution A, 2.3mL of solution B, 2.5mL of solution C and 1.2mL of solution D, mix them and put them into a dry container. Coated on a Mo-coated glass substrate, after heat treatment at 300°C for 10 minutes, the temperature was raised to 450-550°C at a rate of 10-25°C / min, and kept for 45 mi...

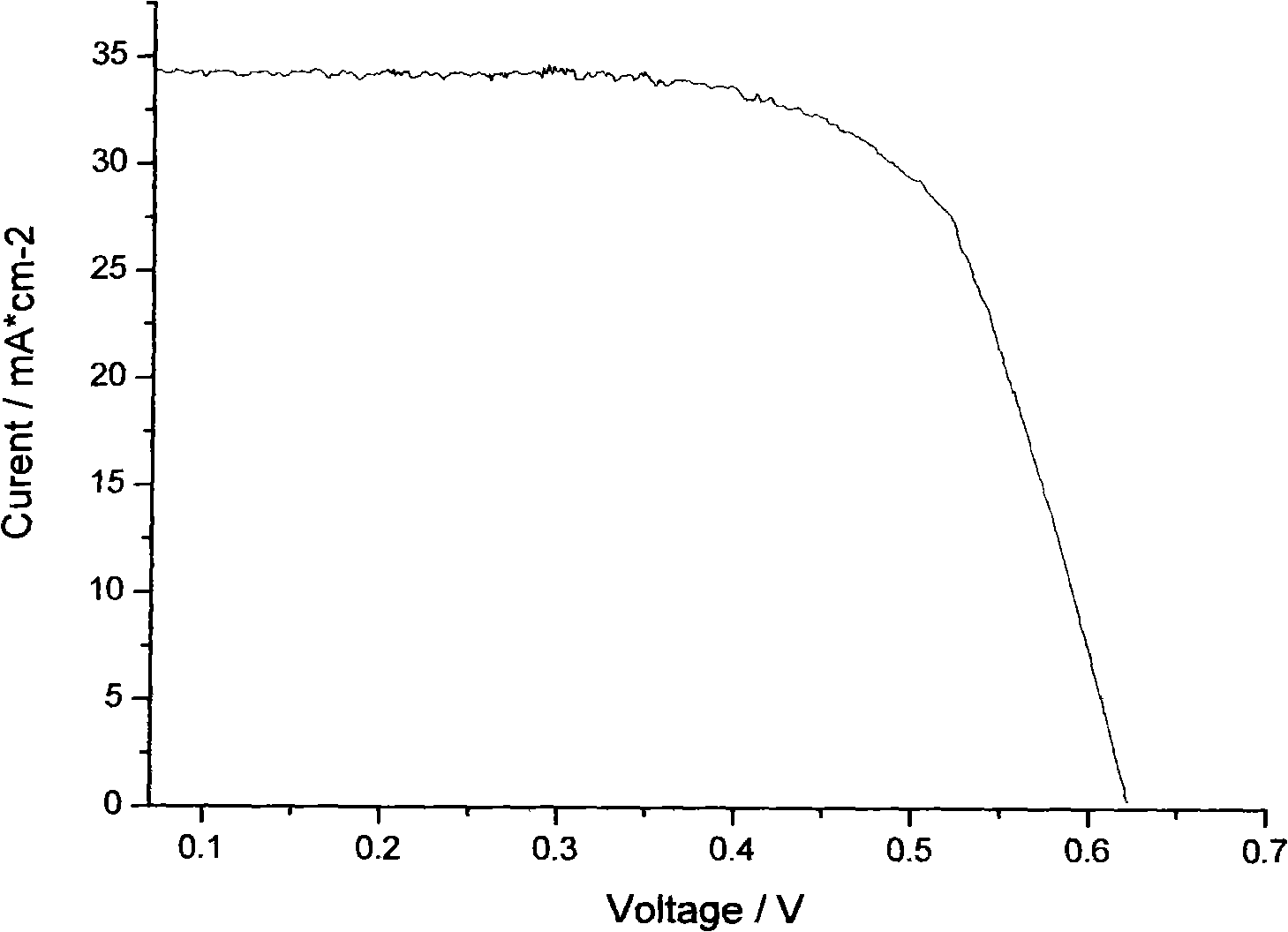

Embodiment 2

[0028] First, the following solutions were prepared respectively in a nitrogen protective atmosphere:

[0029] Prepare solution A: weigh 0.803g of Cu 2 S, 0.321g of S was added to 10mL of hydrazine solution, stirred and reacted for 10h, and left to form solution A;

[0030] Preparation of solution B: 2.3411 g of In 2 Se 3 Prepared by dissolving 0.395g of Se in 10mL of hydrazine solution;

[0031] Prepare solution C: Dissolve 0.956g of Se in 5mL of hydrazine and react.

[0032] Then, pipette 2.0mL of solution A, 2.0mL of solution B, and 2.4mL of solution C, mix them into a dry container, and after fully stirring and filtering, apply the spray method to the Mo-coated glass substrate in a nitrogen atmosphere. After heat treatment at a constant temperature of 300°C for 5 minutes, the temperature was raised to 450-550°C at a rate of 10-25°C / min and kept for 45 minutes to finally obtain CuInSe 2 Thin film, i.e. copper indium selenium thin film, adopts the copper indium gallium ...

Embodiment 3

[0034] First, the following solutions were prepared respectively in a nitrogen protective atmosphere:

[0035] Prepare solution A: weigh 0.955g of Cu 2 S and 0.382g of S were added to 12mL of hydrazine solution, stirred and reacted for 10h, and left to form solution A;

[0036] Preparation of solution B: 1.9434 g of In 2 S 3 Prepared by dissolving 0.1909g of S in 12mL of hydrazine solution;

[0037] Prepare solution C: Dissolve 0.384g of S in 6mL of hydrazine and react.

[0038] Then, pipette 4.0mL of solution A, 4.0mL of solution B, and 1.6mL of solution C respectively, mix them into a dry container, and after fully stirring and filtering, apply spray coating on a Mo-coated glass substrate in a nitrogen atmosphere. After heat treatment at 300°C for 5 minutes, the temperature was raised to 450-550°C at a rate of 10-25°C / min, and kept for 45 minutes to obtain CuInS 2 Thin film, i.e. copper indium sulfur thin film, adopts the copper indium gallium selenium thin film prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com