Organic light-emitting device (OLED) packaging structure and method

An electroluminescent device and packaging structure technology, which is applied in the direction of electro-solid devices, electrical components, semiconductor devices, etc., can solve the problems of different efficiency, slow deposition speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

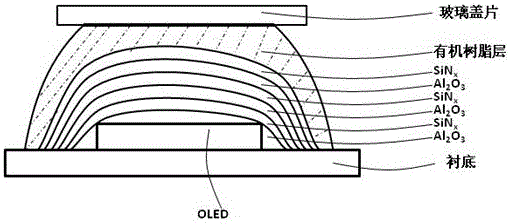

[0032] Such as figure 1 shown.

[0033] A packaging structure of an organic electroluminescent device, which is mainly composed of a substrate substrate, an OLED light-emitting element, a thin film packaging layer, an organic resin layer and a glass cover sheet, and is formed by the following packaging method:

[0034] (1) Form OLED on the base substrate;

[0035] (2) Forming Al on the OLED substrate by atomic layer deposition 2 o 3 film, the precursors used in the deposition process are trimethylaluminum (TMA) and water vapor (H 2 O), injected with nitrogen (N 2 ) as a purge gas; the injection time of trimethylaluminum is 0.02s, the injection time of water vapor is 0.02s, and the injection time of nitrogen is 30s; the chamber pressure is 20Pa, and the deposition temperature is 80°C; Al 2 o 3 The thickness of the film is 30nm;

[0036] (3) in Al 2 o 3Formation of SiN on thin film surface by plasma-enhanced chemical vapor deposition x film, the gas source used in the ...

Embodiment 2

[0042] Such as figure 1 As shown, a packaging structure of an organic electroluminescent device, which sequentially includes a base substrate, an OLED light-emitting element, a thin film packaging layer, an organic resin layer and a glass cover.

[0043] Specifically, the packaging method in this embodiment includes the following steps:

[0044] (1), (2) are the same as embodiment one;

[0045] (3) in Al 2 o 3 SiN is formed on the surface of the film by sputtering x Thin film, the target in the deposition process is a silicon target with a purity of 99.99%, and the background vacuum is 8×10 -4 Pa, the sputtering gas is 99.99% nitrogen and argon respectively, the sputtering power is 400W, the reaction pressure is 0.5Pa, the flow rate of nitrogen gas is 40sccm, and the flow rate of argon gas is 60sccm; SiN x The thickness of the film is 1200nm;

[0046] Steps (4), (5), and (6) steps are the same as in Embodiment 1;

[0047] The water vapor permeability (WVTR) of the OLED ...

Embodiment 3

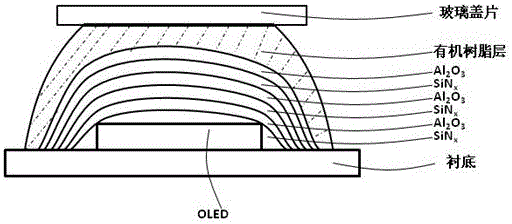

[0049] figure 2 shown.

[0050] A packaging structure of an organic electroluminescent device, which includes a base substrate, an OLED light-emitting element, a thin film packaging layer, an organic resin layer and a glass cover sheet.

[0051] Specifically, the packaging method in this embodiment includes the following steps:

[0052] (1) Form OLED on the base substrate;

[0053] (2) SiN is prepared by plasma-enhanced chemical vapor deposition method on the substrate substrate forming OLED x film, the gas source used in the deposition process is silane (SiH 4 ) and ammonia (NH 3 ), the flow rate of silane is 20sccm, and the flow rate of ammonia gas is 190sccm; the working pressure is 10Pa, and the power is 60W; SiN x The thickness of the film is 1500nm;

[0054] (3) in SiN x Al was formed on the surface of the film by atomic layer deposition 2 o 3 film, the precursors used in the deposition process are trimethylaluminum (TMA) and water vapor (H 2 O), injected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com