Quality-improving technique combining low-rank coal pneumatic drying with multi-tube revolving destructive distillation and system for same

An air dryer and gas flow technology, which is applied in special forms of dry distillation, indirect heating dry distillation, and dry distillation gas discharge devices, etc., can solve the problems of large gas treatment capacity and coking wastewater treatment capacity, and reduce investment and operation. Cost, reduction in discharge, and effect of reducing the amount of hazardous waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

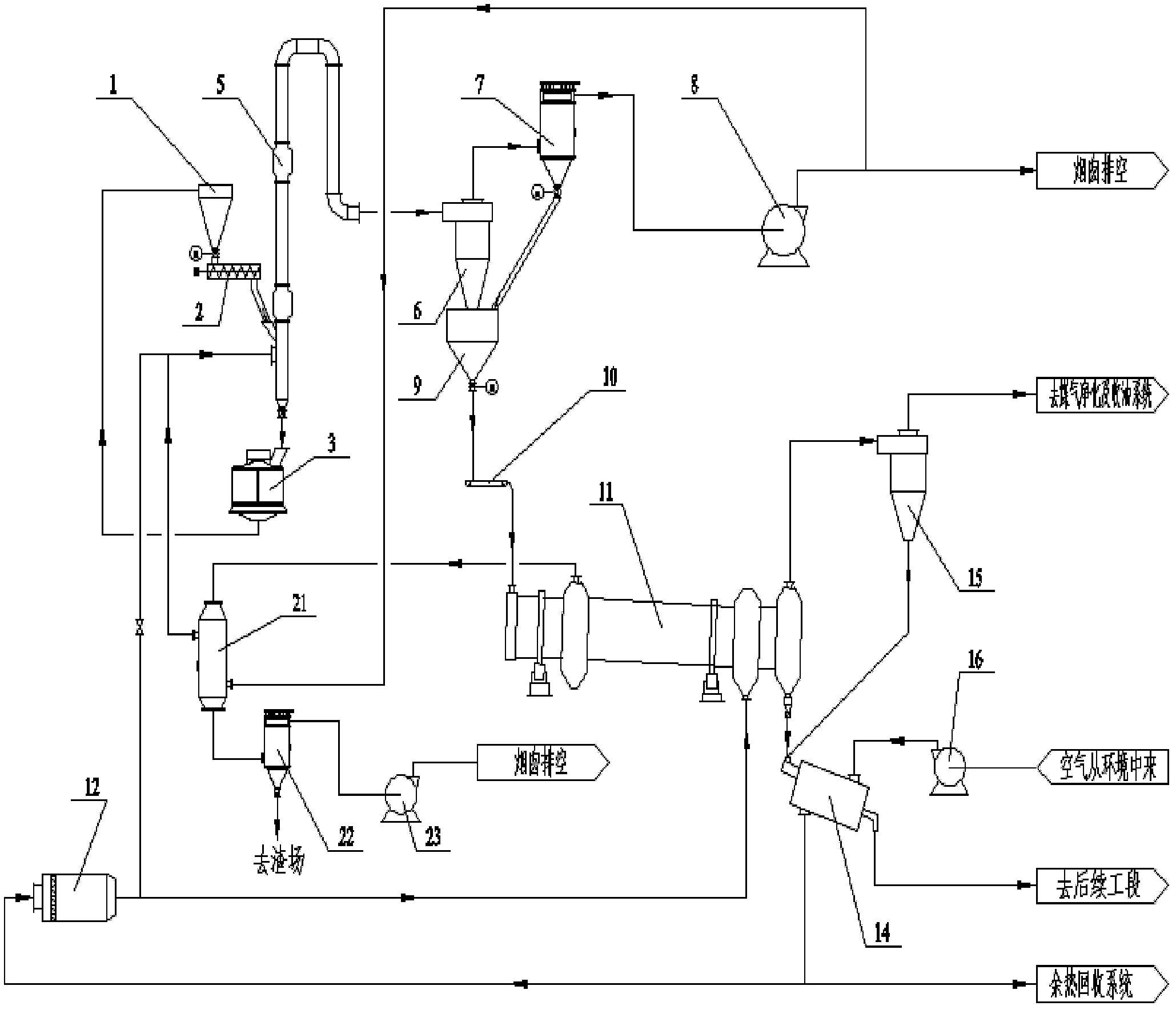

[0056] Embodiment 1: as figure 1 , image 3 Shown, technique of the present invention is as follows:

[0057] Coal process: 0-10mm raw coal from raw coal bunker 1 passes through screw conveyor 2 or other equivalent conveying equipment and then enters air dryer 5 and is mixed with 400-800°C (preferably 500-700°C) from drying mixing chamber 4 Direct contact with high temperature heat medium. The fine coal particles smaller than 5mm (preferably smaller than 3mm) in the coal powder / particles entering the drying system are directly taken away by the hot air after being sorted by the 5 sorting device of the airflow dryer, and dried and dehydrated, while the crushed coal larger than 5mm falls to the The pulverizer 3 at the bottom of the drier is further pulverized to below 5mm (preferably below 3mm), and returns to the raw coal bunker 1. The moisture in the raw coal entering the dryer is instantly heated and vaporized by the high-temperature hot gas to achieve dehydration, and the...

Embodiment 2

[0068] Embodiment 2: as figure 2 , image 3 Shown, technique of the present invention is as follows:

[0069] Coal process: 0-10mm raw coal from raw coal bunker 1 enters air dryer 5 after passing through screw conveyor 2 or other equivalent conveying equipment, and is dried with high-temperature flue gas at 400-800°C (preferably 500-700°C). The mixed flue gas of the backflow tail gas is in direct contact with heat exchange. The fine coal particles smaller than 5mm (preferably smaller than 3mm) in the coal powder / particles entering the drying system are directly taken away by the hot air after being sorted by the 5 sorting device of the airflow dryer, and dried and dehydrated, while the crushed coal larger than 5mm falls to the The pulverizer 3 at the bottom of the drier is further pulverized to below 5mm (preferably below 3mm), and returns to the raw coal bunker 1. The moisture in the raw coal entering the dryer is instantly heated and vaporized by the high-temperature hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com