Preparation method of polyester-modified silica gel

A polyester modification, silica gel technology, applied in the field of silica gel, can solve the problems of poor hardness stability, poor mechanical properties, poor adhesion and mechanical properties, etc., to achieve the effect of good compatibility and widening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

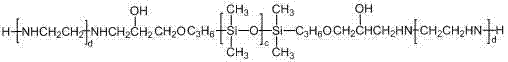

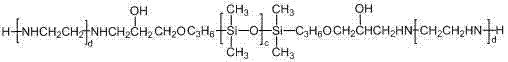

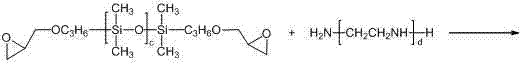

Image

Examples

Embodiment 1

[0038] Put terephthalic acid (PTA), ethylene glycol (EG) monomer and polyethylene glycol 600 (PEG 600) into the reactor at a molar ratio of 2.1:1:1, and then add 0.1% of the total monomer mass The p-toluenesulfonic acid is slowly heated to 110°C, and the solid terephthalic acid (PTA) is dissolved in the polyethylene glycol liquid. then in N 2 Under reduced pressure and vacuum under protection, the reactants were continuously and vigorously stirred with an electric stirrer, and water was gradually distilled out. After 6 hours of constant temperature reaction, when no more water was distilled out, the esterification reaction was completed, and the carboxylated polyester- Polyether block copolymers.

[0039] (2) Preparation of monoamino modified silicone block copolymer:

[0040] Put octamethylcyclotetrasiloxane and tetramethyldisiloxane into the reactor at a mass ratio of 4:1, react at a temperature of 65°C for 0.5h, and then add 0.0005% concentrated Sulfuric acid, at a tempe...

Embodiment 2

[0045]Put terephthalic acid (PTA), ethylene glycol (EG) monomer and polyethylene glycol 800 (PEG 800) into the reactor at a molar ratio of 2.1:1:1, and then add 0.1% of the total monomer mass The p-toluenesulfonic acid is slowly heated to 120°C, and the solid terephthalic acid (PTA) is dissolved in the polyethylene glycol liquid. Then under the protection of N2, the reaction is decompressed and vacuumized, and the reactants are continuously stirred vigorously with an electric stirrer, and water is gradually distilled out. After 4 hours of constant temperature reaction, when no more water is distilled out, the esterification reaction is completed, and the carboxylation reaction is obtained. Polyester-polyether block copolymers.

[0046] (2) Preparation of monoamino modified silicone block copolymer:

[0047] Put octamethylcyclotetrasiloxane and tetramethyldisiloxane into the reactor at a mass ratio of 9:1, react at a temperature of 70°C for 1 hour, and then add concentrated su...

Embodiment 3

[0052] Put terephthalic acid (PTA), ethylene glycol (EG) monomer and polyethylene glycol 400 (PEG 400) into the reactor at a molar ratio of 2.1:1:1, and then add 2% of the total monomer mass The p-toluenesulfonic acid is slowly heated to 115 °C, and the solid terephthalic acid (PTA) is dissolved in the polyethylene glycol liquid. Then under the protection of N2, the reaction is decompressed and vacuumized, and the reactant is continuously and vigorously stirred with an electric stirrer, and water is gradually distilled out. After 5 hours of constant temperature reaction, when no more water is distilled out, the esterification reaction is completed, and the carboxylation reaction is obtained. Polyester-polyether block copolymers.

[0053] (2) Preparation of monoamino modified silicone block copolymer:

[0054] Put octamethylcyclotetrasiloxane and tetramethyldisiloxane into the reactor at a mass ratio of 19:1, react at 60°C for 0.75h, and then add concentrated sulfuric acid acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com