Waterborne epoxy acrylate-grafted composite emulsion and preparation method thereof

A technology of epoxy acrylate and epoxy acrylic acid, which is applied in the field of preparation of water-based epoxy acrylate grafted composite emulsion, can solve the problems of organic solvent pollution, poor storage stability, low grafting rate, etc., achieve good adhesion, improve High compatibility and high grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of epoxy acrylate

[0045] 0.4g of tetrabutylammonium bromide and 2.0g of acrylic acid monomer were mixed evenly and dissolved for later use. Put 20.0g of E-51, 0.05g of hydroquinone and 40.0g of methyl methacrylate dispersion medium into the four-necked bottle, heat up to 100°C within 40 minutes, and drop the uniformly mixed catalyst and acrylic acid mixture, Adding time is controlled within 50 minutes. After the dropwise addition, keep the temperature at 110°C for one hour, measure the acid value until the acid value is less than 5mgKOH / g resin, then cool down to room temperature.

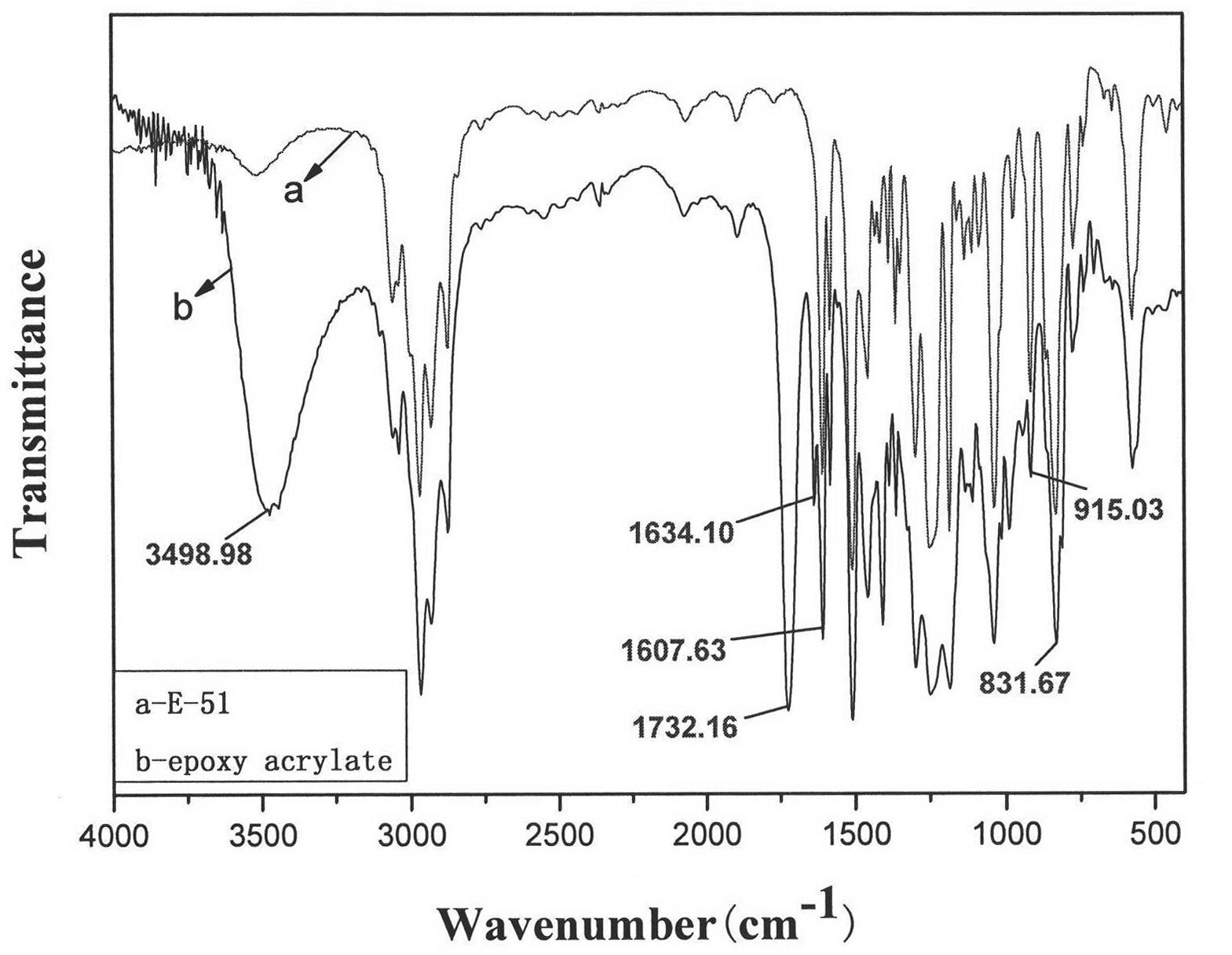

[0046] The above reaction products were separated, and then analyzed by infrared spectrum and hydrogen nuclear magnetic resonance spectrum. figure 1 It is the infrared spectrogram of the reaction product of epoxy resin E-51 and epoxy acrylate. Of which 915.03cm -1 Is the absorption peak of epoxy group, 831.67cm -1 The place is the absorption peak of two adjacent H atoms on...

Embodiment 2

[0057] As shown in Table 1, the raw materials used are the same as in Example 1 except that the reactant soft monomer butyl acrylate is changed to ethyl acrylate.

[0058] The implementation data of table 1 embodiment 2

[0059] Ingredients ratio and reaction conditions

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com