Method for eliminating carbon contamination of platinum-containing components for a glass making apparatus

A technology for glass manufacturing and equipment, applied in the field of eliminating carbon pollution of platinum-containing parts used in glass manufacturing equipment, capable of solving problems such as contamination of molten glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

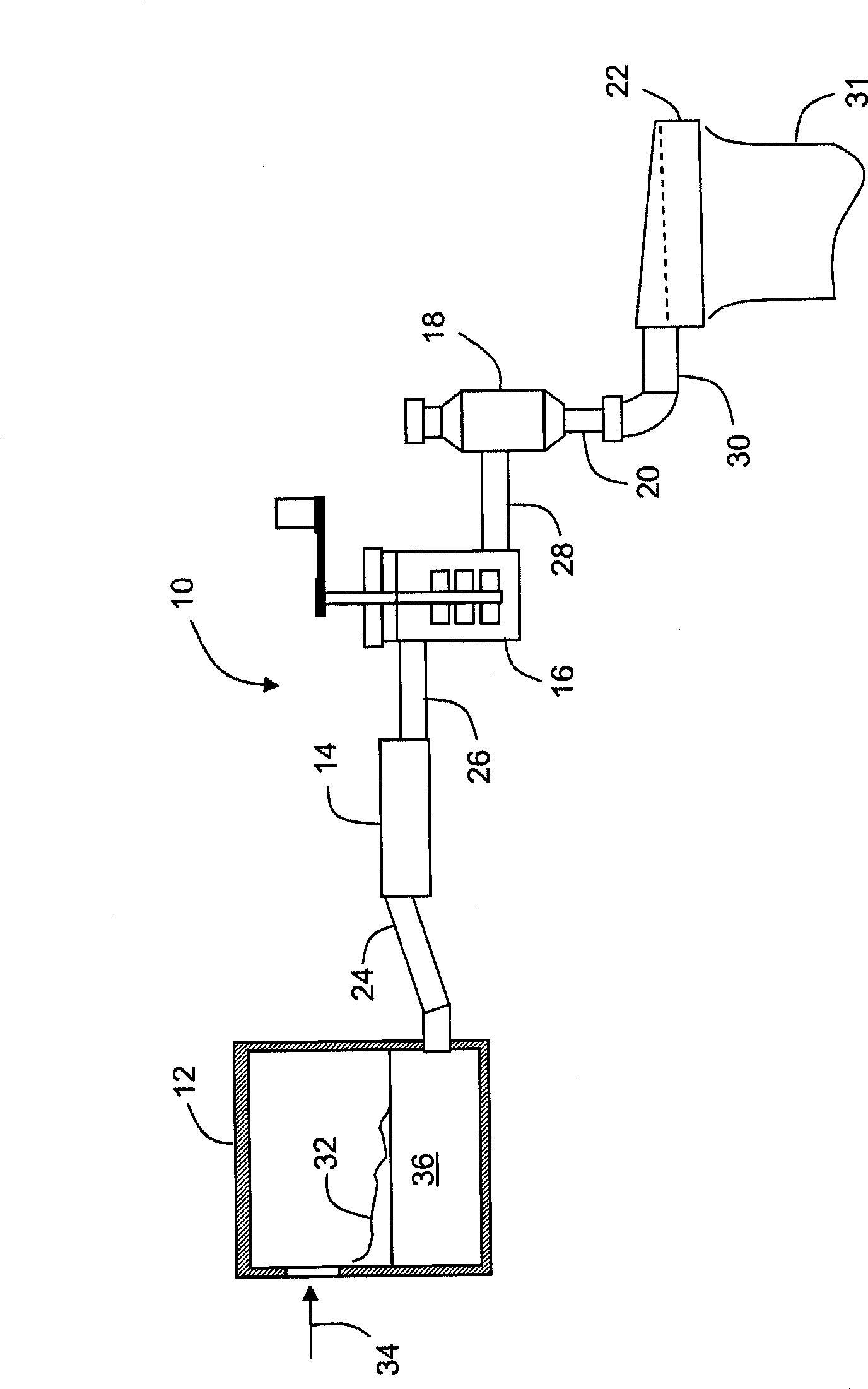

[0033] In the following detailed description, for purposes of illustration and not limitation, example embodiments are set forth in numerous specific details in order to provide a thorough understanding of the present invention. However, it will be apparent to those of ordinary skill in the art, having reference to the disclosure herein, that the invention may be practiced in other embodiments without departing from the specific details disclosed herein. Moreover, descriptions of well-known devices, methods and materials are omitted so as not to obscure the description of the present invention. Finally, as far as possible, the same components are designated with the same reference numerals.

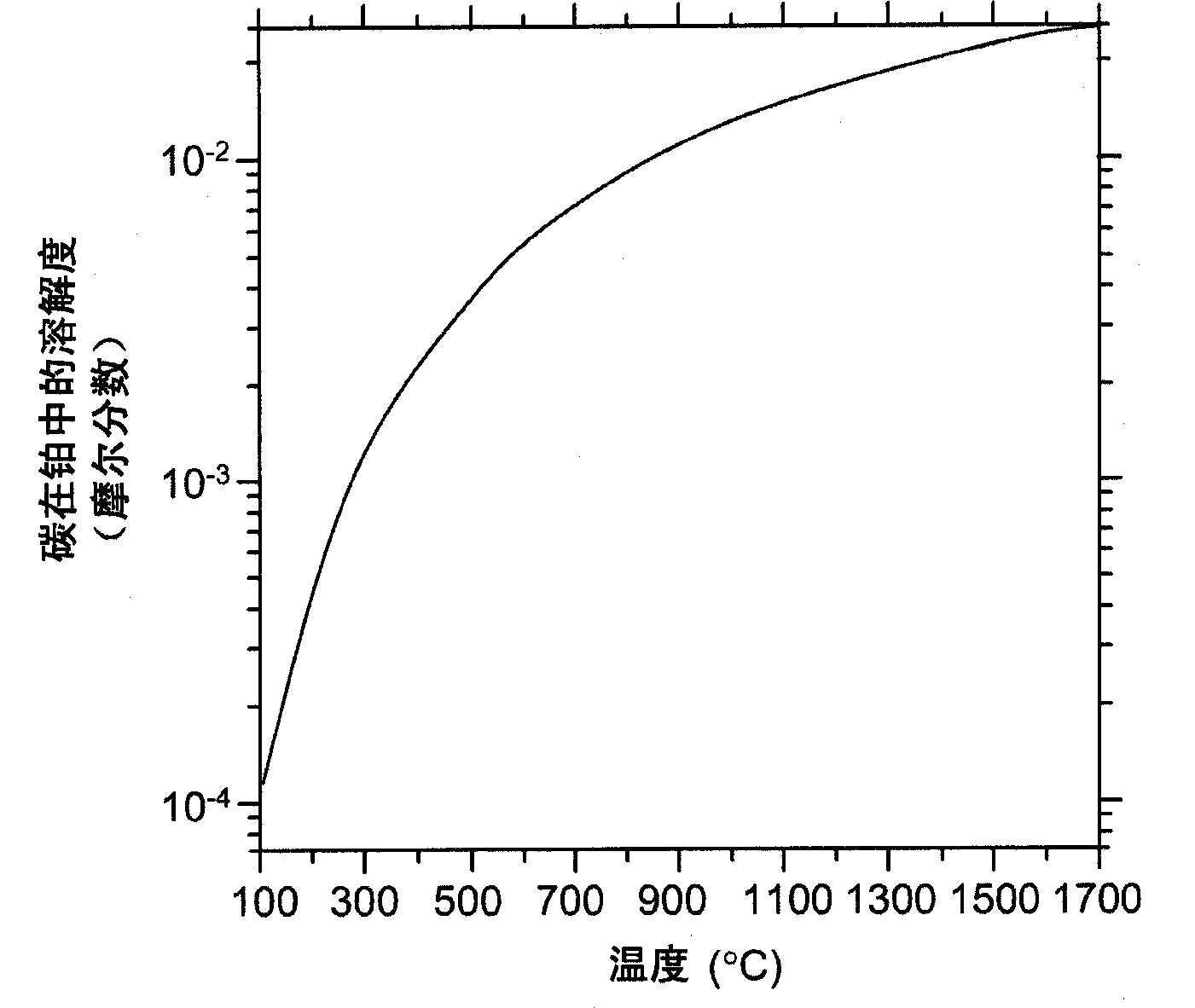

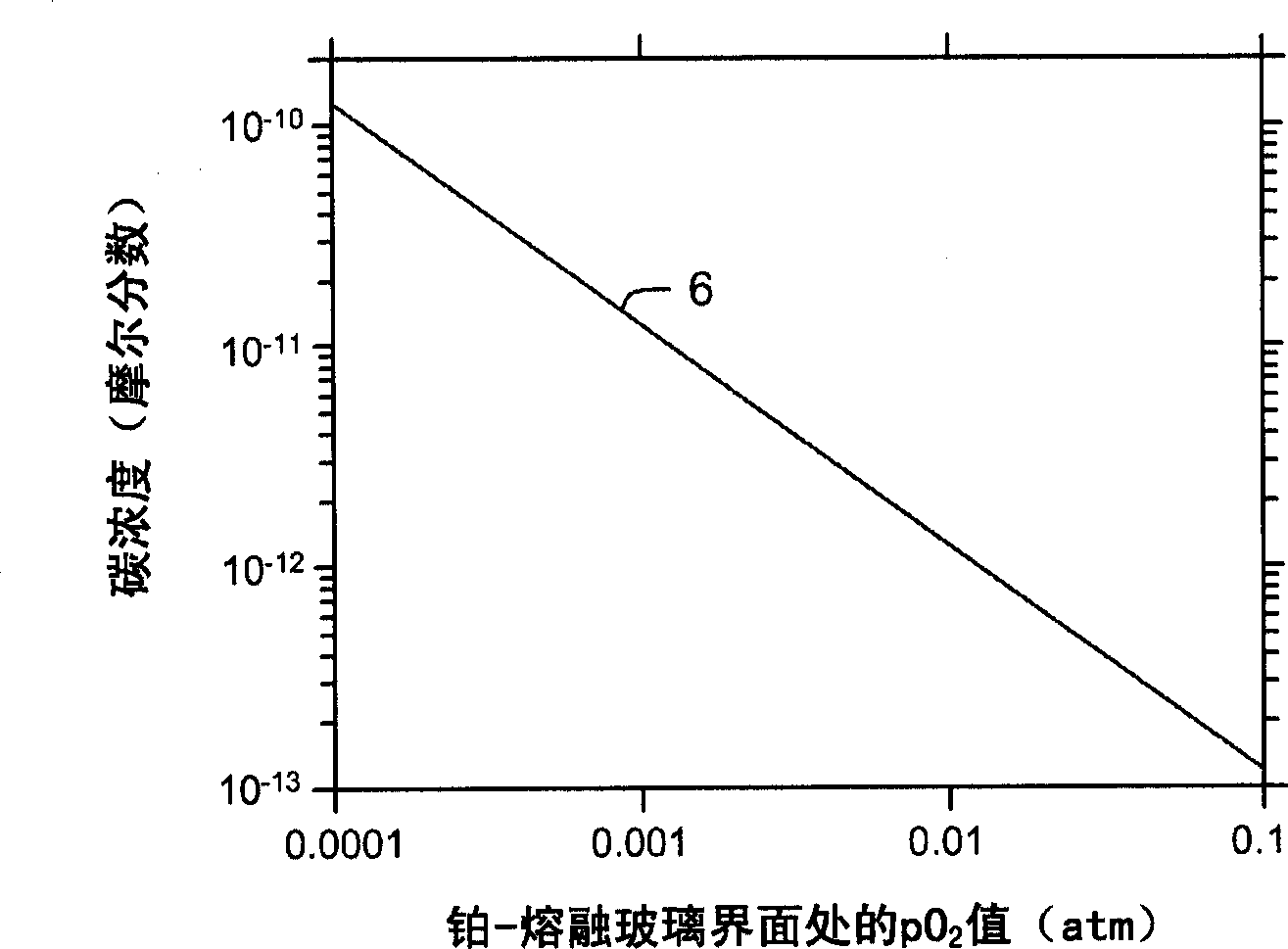

[0034] Many modern glassmaking systems employ precious metal components for conveying and / or handling the molten glass material once it is formed by melting the batch. Typical noble metals include metals selected from the platinum group metals including platinum, rhodium, iridium, ruthen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com