Calcium-resistant soyabean protein and preparation method thereof

A soybean protein and calcium tolerance technology, applied in the field of soybean protein, can solve problems such as poor calcium tolerance, and achieve the effect of reducing co-precipitation, weakening electrostatic interaction and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

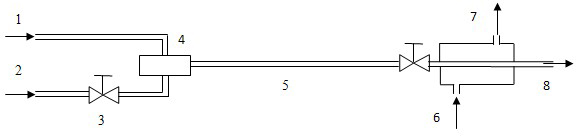

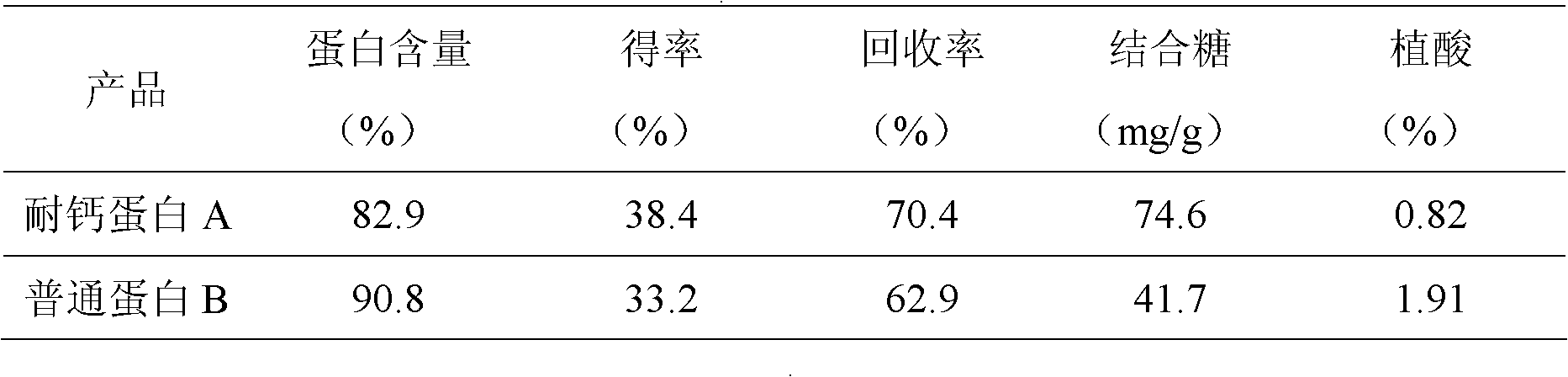

[0026] The low-temperature defatted soybean meal (NSI=89, protein content 51%) was pulverized and passed through a 60-mesh sieve to obtain the defatted soybean powder, mixed with water according to the mass-volume ratio of 1:10, added 0.08% sodium sulfite by weight of the soybean powder, and heated at room temperature and pH8 0 under the condition of stirring for 1.5 hours, then homogenized 20min in the colloid mill, the obtained defatted soy flour slurry was figure 1 Jet cooking is carried out in the continuous heat treatment device shown, the treatment temperature is 140°C, and the time is 90s. After the obtained heat treatment slurry is cooled, the pH value is adjusted to 8.0 with 2mol / L NaOH, centrifuged at 25°C for 30min, and the centrifugal speed is 3000rpm. The final supernatant was adjusted to pH 4.5 with 2mol / L HCL, left to stand for 5 minutes, and centrifuged at 25°C for 30 minutes at a speed of 5000 rpm. ℃, air outlet temperature 85 ℃), to obtain calcium-tolerant so...

Embodiment 2

[0038] The defatted soybean meal (NSI=89, protein content 51%) was crushed and passed through a 60-mesh sieve to obtain the defatted soybean powder, mixed with water according to the mass-volume ratio of 1:10, adding 0.15% sodium sulfite of soybean powder weight, and using 2mol / L NaOH adjusted the pH value to 8.0 and stirred at room temperature for 2 hours, then homogenized in a colloid mill for 10 minutes, and the obtained defatted soybean flour slurry was figure 1 Jet cooking treatment is carried out in the continuous heat treatment device shown, the temperature and time are respectively 120°C, 90s (E) and 140°C, 30s (F), the obtained heat treatment slurry is cooled, adjusted to pH 8.0, and centrifuged at 25°C for 30min, the centrifugal speed After centrifugation, the supernatant was adjusted to pH 4.5 with 2 mol / L of HCL. After standing for 5 minutes, it was centrifuged at 25°C for 30 minutes at a speed of 5000 rpm. The resulting precipitate was re-dissolved in water, adjust...

Embodiment 3

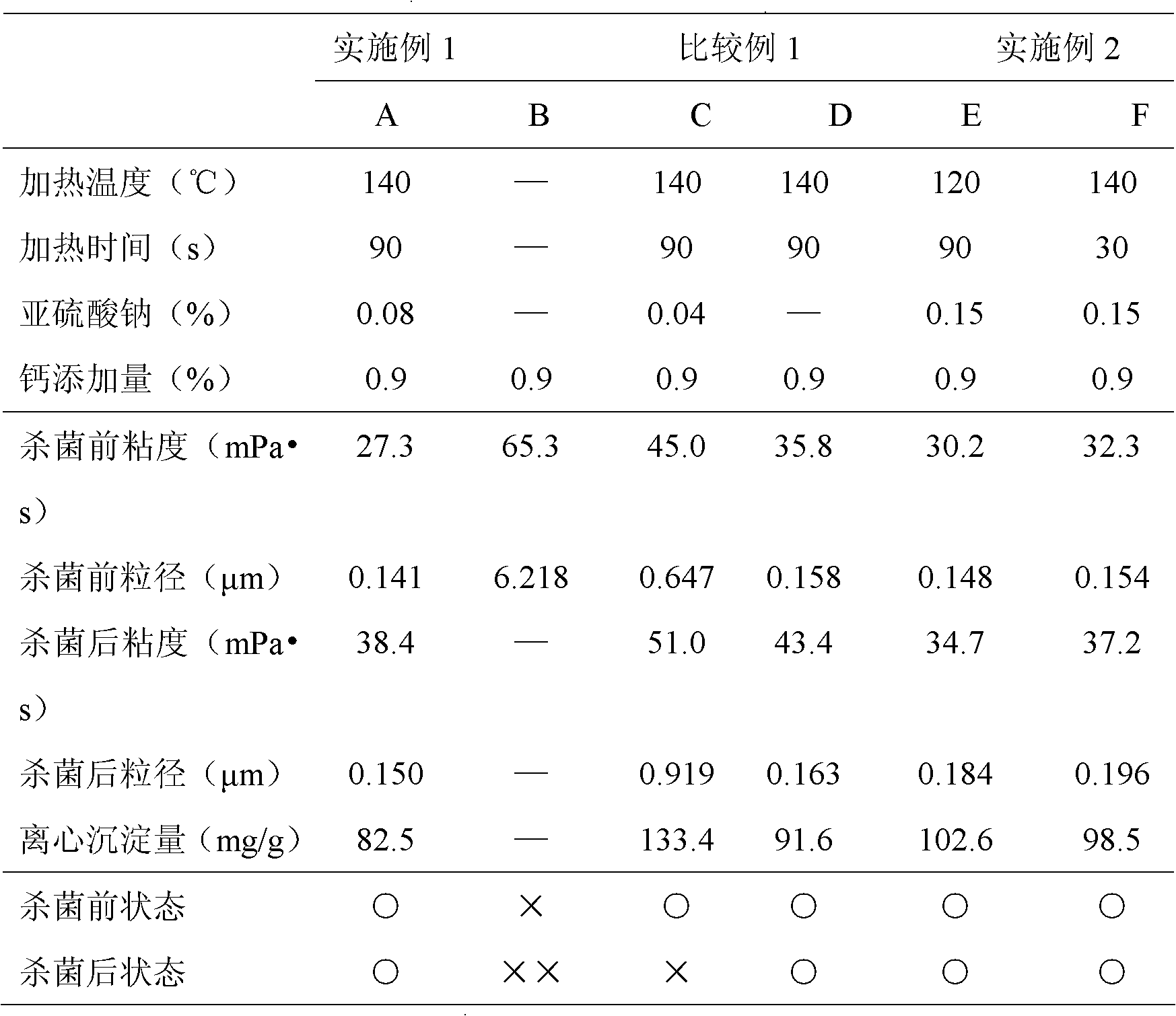

[0040] The soybean protein raw materials obtained in the above-mentioned Examples 1, 2 and Comparative Example 1 are mixed with corresponding ingredients to prepare calcium-enriched soybean protein liquid food. Maltodextrin, 0.4g sodium citrate and 0.2g calcium chloride (the amount of calcium added is based on the amount of calcium ions, which is 0.9% of the weight of protein raw materials), add 64.9g water and stir well, and use 2mol / L HCL and NaOH Adjust the pH to 7.0, then add 2.5g of corn oil and homogenize at a speed of 20000rpm for 2 minutes, then homogenize the mixture twice at 50MPa, and finally sterilize the mixture in a sterilizing pot at 121°C and 0.1MPa. Bacteria 20min. Among them, the properties and states of each sample before and after sterilization were measured and evaluated, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com