TiAl based alloy metallographic specimen corroding method

A technology for metallographic samples and base alloys, which is applied in the field of corrosion of TiAl-based alloy metallographic samples and the preparation of metallographic samples, can solve the problems that the structure of TiAl-based alloys is difficult to clearly display, and achieve rich information inside the grains Meticulous, complete and clear grain boundaries, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

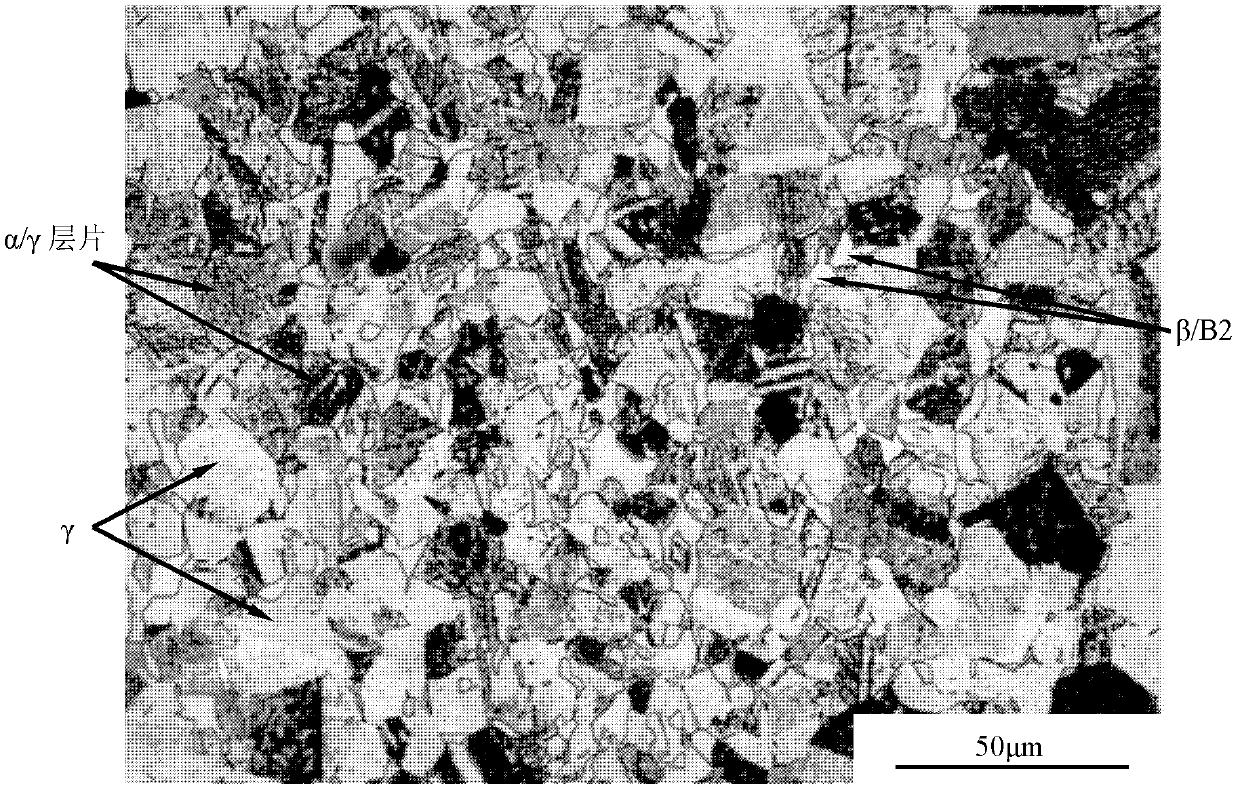

Embodiment 1

[0030] Cut the sample from the hot isostatic pressed alloy prepared by powder metallurgy method, prepare a qualified metallographic sample according to the standard method, and then immerse the above sample in the electrolytic solution for electrolysis corrosion. The electrolytic solution contains 30mL of hydrofluoric acid (HF), 10g of boric acid (H 3 BO 3 ), the balance is distilled water. The selected electrolytic voltage was 16V, and the electrolytic corrosion time was 40s. Immediately after electrolytic corrosion, it was washed with clean water and dried; the bright field image was observed on an ordinary optical metallographic microscope, and the attached figure 1 When the magnification is 500×, the clear and beautiful metallographic structure picture is obtained.

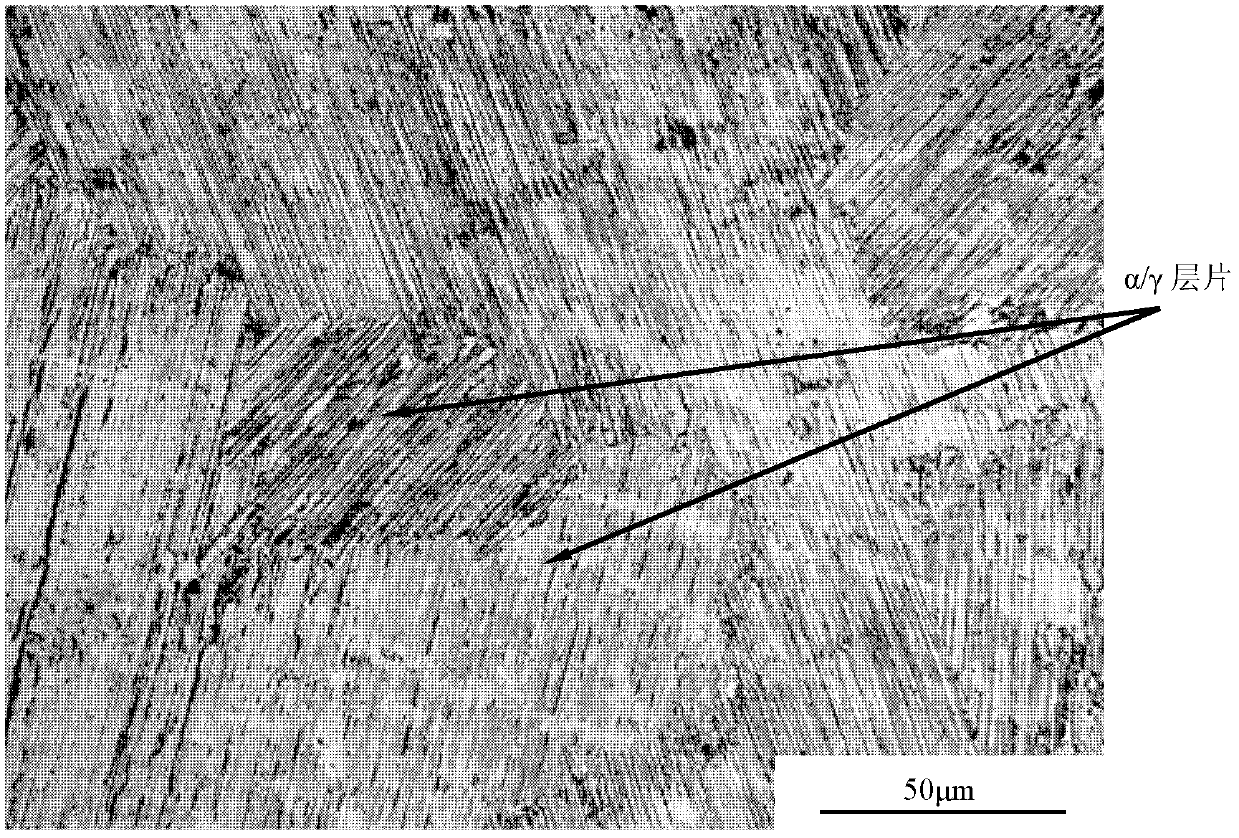

Embodiment 2

[0032] Cut the sample from the cast alloy whose composition is Ti-47Al-2Cr-0.2Mo prepared by the vacuum induction arc melting method, prepare a qualified metallographic sample according to the standard method, and then immerse the above sample in the electrolytic solution for electrolytic corrosion . The electrolytic solution contains 40mL of hydrofluoric acid (HF), 11g of boric acid (H 3 BO 3 ), the balance is distilled water. The selected electrolytic voltage was 16V, and the electrolytic corrosion time was 120s. Immediately after electrolytic corrosion, it was washed with water and dried; the bright field image was observed on an ordinary optical metallographic microscope, and the attached figure 2 When the magnification is 500×, the clear and beautiful metallographic structure picture is obtained.

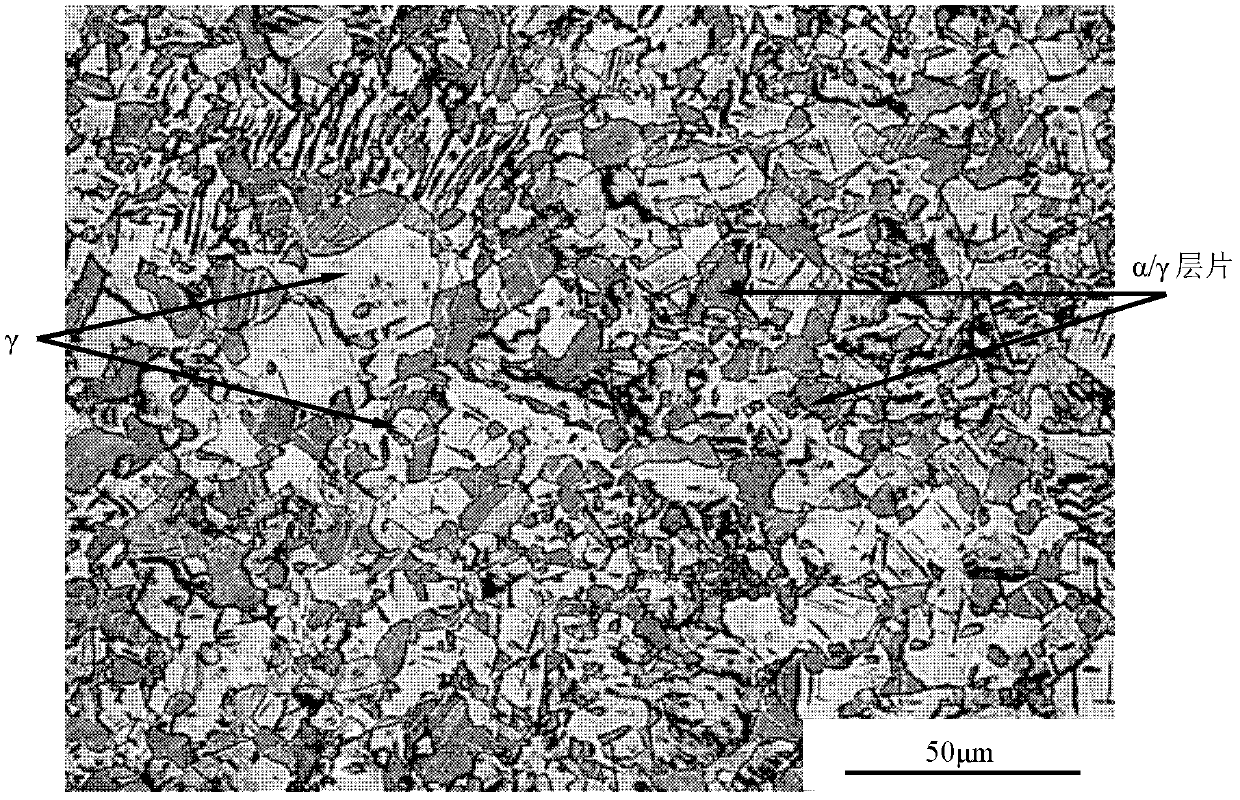

Embodiment 3

[0034] Cut the sample from the forging cake material whose composition is Ti-47Al-2Cr-0.2Mo alloy under the condition of 1200 ℃, and the total deformation deformation is 70%, prepare a qualified metallographic sample according to the standard method, and then The above samples were immersed in electrolytic solution for electrolytic corrosion. The electrolytic solution contains 35mL of hydrofluoric acid (HF), 11g of boric acid (H 3 BO 3 ), the balance is distilled water. The selected electrolytic voltage was 16V, and the electrolytic corrosion time was 120s. Immediately after electrolytic corrosion, it was washed with water and dried; the bright field image was observed on an ordinary optical metallographic microscope, and the attached image 3 When the magnification is 500×, the clear and beautiful metallographic structure picture is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com