Cable sheath material for wind power generation and production method thereof

A technology for cable sheathing and wind power generation, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor physical and mechanical properties of the sheath, unsatisfactory cable effects, etc., and achieve good low-temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

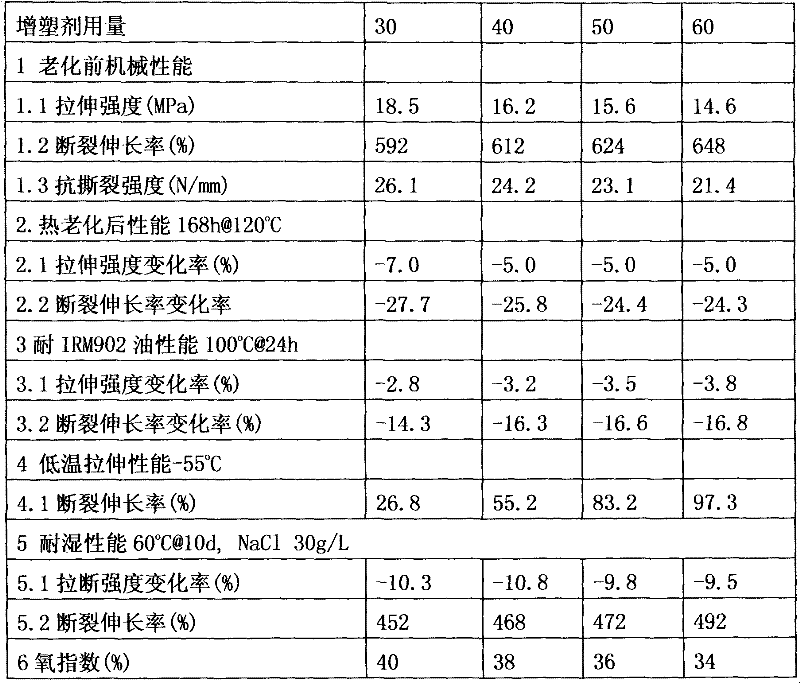

Embodiment 1

[0022] Take 100 parts of chlorosulfonated polyethylene rubber, 15 parts of PbO, 2 parts of bispentamethylene thiuram hexasulfide, 1 part of bispentamethylene thiuram hexasulfide, vulcanization aid N, N'-m-phenylene bis 1 part of maleimide, 20 parts of MgO, reinforcing agent SiO 2 40 parts, antioxidant N, N-dibutyl dithiocarbamate nickel 2 parts, plasticizer dioctyl sebacate (DOS) (30, 40, 50, 60) parts, flame retardant 30 parts of antimony, 20 parts of synergistic flame retardant decabromodiphenyl ether, 4 parts of coupling agent γ-glycidyloxypropyl trimethoxysilane (KH560), 3 parts of vaseline as processing aid, 2 parts of stearic acid. The implementation results are shown in Table 1.

Embodiment 2

[0024] Take 100 parts of chlorosulfonated polyethylene rubber, 15 parts of PbO, 2 parts of bispentamethylene thiuram hexasulfide, bispentamethylene thiuram hexasulfide, vulcanization aid N, N'-m-phenylene bismaleyl 1 part of imine, 20 parts of MgO, reinforcing agent SiO 2 40 parts, antioxidant N, N-dibutyl dithiocarbamate nickel 2 parts, plasticizer dioctyl sebacate (DOS) 60 parts, flame retardant antimony trioxide 20, 30, 40 parts, Synergistic flame retardant decabromodiphenyl ether 10, 20, 30 parts, coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (KH560) 4 parts, processing aid vaseline 3 parts, stearic acid 2 parts. The implementation results are shown in Table 2

Embodiment 3

[0026] Take 100 parts of chlorosulfonated polyethylene rubber, 15 parts of PbO, 2 parts of bispentamethylene thiuram hexasulfide, 1 part of bispentamethylene thiuram hexasulfide, vulcanization aid N, N'-m-phenylene bisma 1 part of imide, 20 parts of MgO, reinforcing agent SiO 2 30, 40, 60 parts, antioxidant N, N-dibutyl dithiocarbamate nickel 2 parts, plasticizer dioctyl sebacate (DOS) 60 parts, flame retardant antimony trioxide 40 parts, Synergistic flame retardant decabromodiphenyl ether 30 parts, coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (KH560) 4 parts, processing aid vaseline 3 parts, stearic acid 2 parts. The implementation results are shown in Table 3.

[0027] In the above examples, chlorosulfonated polyethylene has a fully saturated main chain and side groups, so the vulcanized rubber of chlorosulfonated polyethylene has excellent ozone resistance and aging resistance, and has excellent heat resistance, oil resistance, Chemical and aging resistance. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com