Manganese phosphate lithium and carbon nanometer pipe situ compounding anode material and preparation method thereof

A technology of carbon nanotubes and lithium manganese phosphate, which is applied in the field of electrochemistry, can solve problems such as uneven coating and material conductivity limitations, and achieve the effects of simple preparation process, excellent high-rate performance, and improved electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Li 2 CO 3 , NH 4 h 2 PO 4 and MnCO 3 Lithium source, phosphorus source and manganese source, with Fe 2 o 3 as a catalyst. Weigh according to the stoichiometric ratio of Li, Mn, Fe, P 1.02:0.99:0.01:1, dissolve in a certain amount of ethanol solution to obtain a slurry with a solid content of 60%, according to the mass ratio of ball to material 5:1 The mixture was ball milled at a speed of 300 r / min for 17 hours, and then dried with stirring at 80°C. The powder material obtained by drying and grinding is placed in a rotary kiln. In a mixed atmosphere of 10% acetylene and 90% nitrogen with a gas flow rate of 10L / min, the temperature was raised to 700°C at 5°C / min and roasted at a constant temperature for 14 hours, and then slowly cooled to room temperature in the furnace to obtain gray-black LiMn. 0.99 Fe 0.01 PO 4 / carbon nanotube composites.

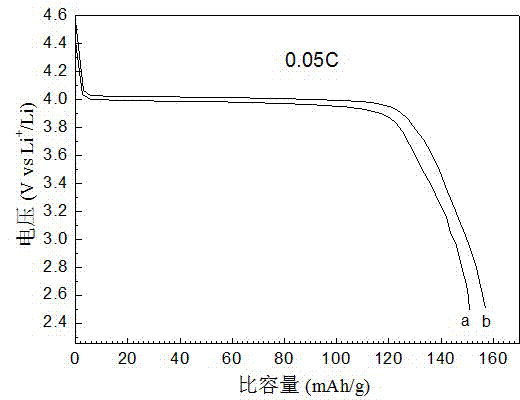

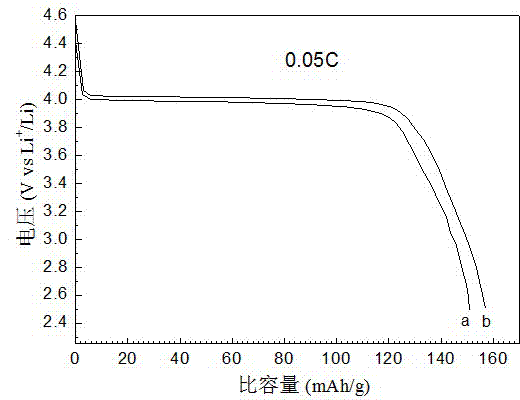

[0028] The lithium manganese phosphate material obtained in Example 1 was used to make electrodes according to the ...

Embodiment 2

[0032] Respectively with LiOH, NH 4 h 2 PO 4 and Mn(OH) 2 Lithium source, phosphorus source and manganese source, with Ni(OH) 2 as a catalyst. Weigh according to the ratio of Li, Mn, Ni, P stoichiometric ratio 1.02:0.99:0.01:1, dissolve in a certain amount of acetone solution to obtain a slurry with a solid content of 80%, according to the mass ratio of ball to material 10:1 The mixture was ball milled at 600 r / min for 10 hours, and then dried under stirring at 60°C. The powder material obtained by drying and grinding is placed in a rotary kiln. In a mixed atmosphere of 10% ethane and 90% nitrogen at a gas flow rate of 10L / min, the temperature was raised to 650°C at a rate of 5°C / min and roasted at a constant temperature for 16 hours, and then slowly cooled to room temperature in the furnace to obtain gray-black LiMn. 0.99 Ni 0.01 PO 4 / carbon nanotube composites. Its discharge curve at 0.05 C rate (1C=170 mAh / g) is as follows figure 1 Shown in b.

Embodiment 3

[0034] Li 2 CO 3 , (NH 4 ) 2 HPO 4 and Mn(OH) 2 Lithium source, phosphorus source and manganese source, Fe(OH) 3 as a catalyst. Weigh according to the stoichiometric ratio of Li, Mn, Fe, P 1.05:0.98:0.02:1, dissolve in a certain amount of ethanol solution to obtain a slurry with a solid content of 70%, according to the mass ratio of balls to materials 8:1 The mixture was ball milled at a speed of 400 r / min for 18 hours, and then dried with stirring at 70°C. The powder material obtained by drying and grinding is placed in a rotary kiln. In a mixed atmosphere of 10% ethylene and 90% nitrogen at a gas flow rate of 10L / min, the temperature was raised to 750°C at 5°C / min and roasted at a constant temperature for 12 hours, and then slowly cooled to room temperature in the furnace to obtain gray-black LiMn. 0.98 Fe 0.02 PO 4 / carbon nanotube composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com