Green multifunctional composite aid for wood plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and composite additives, which is applied in the field of materials, can solve problems such as poor durability, uncertain additive effect, and cumbersome adding process, and achieve the effects of good durability, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

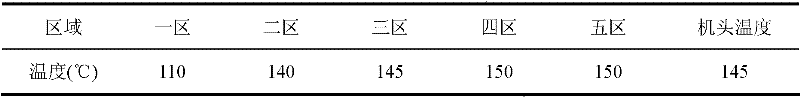

Embodiment 1

[0069] 50g of sodium-based montmorillonite (CEC is 70mmol / 100g) (see the literature for the specific treatment method of sodium-based: Tan Shaozao, Zhang Kuihua, Li Duxin, Liu Yingliang, Zhang Yuanming. Quaternary phosphonium salt modified montmorillonite Preparation and properties of soil [J]. Journal of Central South University (Natural Science Edition), 2006, 37(2): 280-285.) Disperse in 1000mL distilled water, stir at 50rpm for 30min at 40°C, add 1 times The dedecyltrimethylphosphonium chloride (molecular weight is 258.5) 13g of montmorillonite CEC, under 90 ℃ with the speed stirring reaction of 50rpm 4h, filter, the solid that obtains is dehydrated alcohol: water=1: 2 (volume than) ethanol aqueous solution to wash to no bromide or chloride ion (bromide or chloride ion is the ionized ion after the organic cation is dissolved in water, the purpose of this step is to ensure that all unreacted organic cations are washed away), then Vacuum dry at 100°C for 45h (vacuum degree i...

Embodiment 2

[0079] Vermiculite (CEC is 80mmol / 100g) after 50g of sodium-based (CEC is 80mmol / 100g) (see the literature for the specific treatment method of sodium-based: Tan Shaozao, Zhang Kuihua, Li Duxin, Liu Yingliang, Zhang Yuanming. Quaternary phosphonium salt modified montmorillonite Preparation and properties of [J]. Journal of Central South University (Natural Science Edition), 2006, 37(2): 280-285.) Dispersed in 1000mL distilled water, stirred at 50rpm at 40°C for 30min, then added 1.1 times of leech Hexadecyldimethylbenzylphosphonium bromide (molecular weight is 458) 29g of stone CEC, under 80 ℃ with the speed stirring reaction of 50rpm 5h, filter, the solid that obtains is dehydrated with ethanol: water=1: 1 ( volume ratio) of ethanol aqueous solution to be free of bromide or chloride ion (bromide or chloride ion is the ionized ion after organic cation is dissolved in water, and the purpose of this step is to guarantee that all unreacted organic cations are all washed away), Th...

Embodiment 3

[0089] 50g of sodium-based attapulgite (CEC is 55mmol / 100g) (see the literature for the specific treatment method of sodium-based: Tan Shaozao, Zhang Kuihua, Li Duxin, Liu Yingliang, Zhang Yuanming. Quaternary phosphonium salt modified montmorillonite Preparation and properties of soil [J]. Journal of Central South University (Natural Science Edition), 2006, 37(2): 280-285.) Disperse in 1000mL distilled water, stir at 50rpm for 30min at 40°C, add 1.2 times Attapulgite CEC bis-hexadecyldimethylethylphosphonium bromide (molecular weight: 761) 39g, stirred at 50rpm at 70°C for 6h, filtered, and the obtained solids were mixed with absolute ethanol: water = 2 : 1 (volume ratio) ethanol aqueous solution to wash to no bromide or chloride ion (bromide or chloride ion is ionized after organic cation dissolves in water, the purpose of this step is to ensure that all unreacted organic cations are washed removed), and then vacuum-dried at 120°C for 55h (vacuum degree is 3×10 4 Pa), and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com