Method for preparing release paper with concave-convex grooved texture

A technology of concave-convex and release paper, which is applied in the field of light industry papermaking, can solve the problems of complex production process, large amount of silicone oil, and high production cost of release paper, and achieve the effects of simplifying the production process, low cost, and improving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

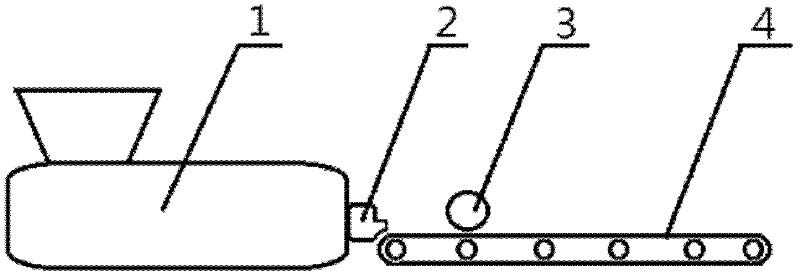

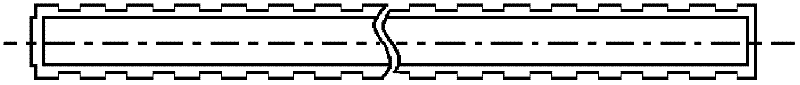

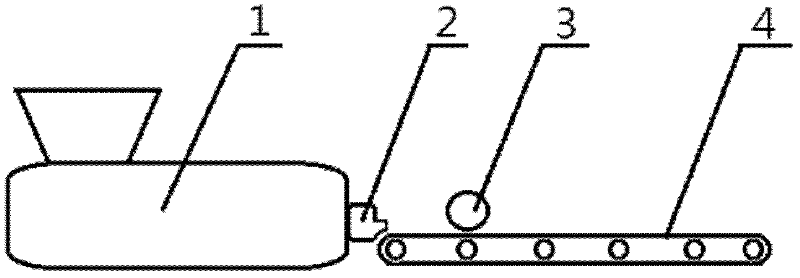

[0029] Add 70kg of calcium carbonate with a particle size of 2000 mesh into a high-speed mixer, and heat it to 120°C, then add 1kg of titanate coupling agent, stir at high speed for 30min, then add 14kg of polyethylene, 1kg of maleic anhydride modified polyethylene, 2kg of polyethylene wax and 1kg of azodicarbonamide were heated to 150°C, stirred at a high speed for 60 minutes, and then 2kg of silicone oil was added and stirred for 30 minutes to obtain a mixture. Then the mixture is sent to the paper film equipment, and the mixture becomes molten at 170°C and is inflated by the die head of the paper film machine to make a paper film, and then passes through the concave-convex embossing set behind the die head of the paper film machine After the round shaft is rolled, the surface is grooved and embossed, and the release paper with concave and convex grooves is cooled.

[0030] The paper film is rolled through a circular shaft with concave-convex embossing at a speed of 80m / min....

Embodiment 2

[0032] Add 85kg of talc powder with a particle size of 1000 mesh into the high-speed mixer, and after heating to 130°C, add 1kg of silane coupling agent respectively, after stirring at high speed for 50min, add 30kg of polyethylene, 4kg of maleic anhydride-modified polypropylene, and 2kg of paraffin wax 1. 0.5kg of azodicarbonamide, heated to 150°C, stirred at a high speed for 60 minutes, then added 3kg of silicone oil and continued to stir for 30 minutes to obtain a mixture. Then the mixture is sent to the paper film equipment, and the mixture becomes molten at 180°C and is inflated by the die head of the paper film machine to make a paper film, and then passes through the concave-convex embossing set behind the die head of the paper film machine After the round shaft is rolled, the surface is grooved and embossed, and the release paper with concave and convex grooves is cooled.

[0033] The paper film is rolled through a circular shaft with concave-convex embossing at a spee...

Embodiment 3

[0035] Add 50kg of talc powder with a particle diameter of 800 mesh and 20kg of calcium carbonate with a particle diameter of 2000 mesh into a high-speed mixer, and heat it to 140°C, add 1.5kg of titanate coupling agent, stir at high speed for 30 minutes, and then add 15kg of polyethylene , 3kg of maleic anhydride modified polyethylene, 1kg of polyethylene wax, and 1kg of ammonium carbonate were heated to 150°C, stirred at high speed for 55 minutes, and then added with 4kg of methyl silicone oil and continued to stir for 30 minutes to obtain a mixture. Then the mixture is sent to the paper film equipment, and the mixture becomes molten at 200°C and is inflated by the die head of the paper film machine to make a paper film, and then passes through the concave-convex embossing set behind the die head of the paper film machine After the round shaft is rolled, the surface is grooved and embossed, and the release paper with concave and convex grooves is cooled.

[0036] The paper f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com