Super-hydrophobic ice-covering-proof coating having slowly-releasing function and preparation method thereof

A super-hydrophobic and anti-icing technology, applied in the coating and other directions, can solve the problem that the anti-icing coating cannot achieve the anti-icing effect, and achieve the effect of anti-icing, simple preparation process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

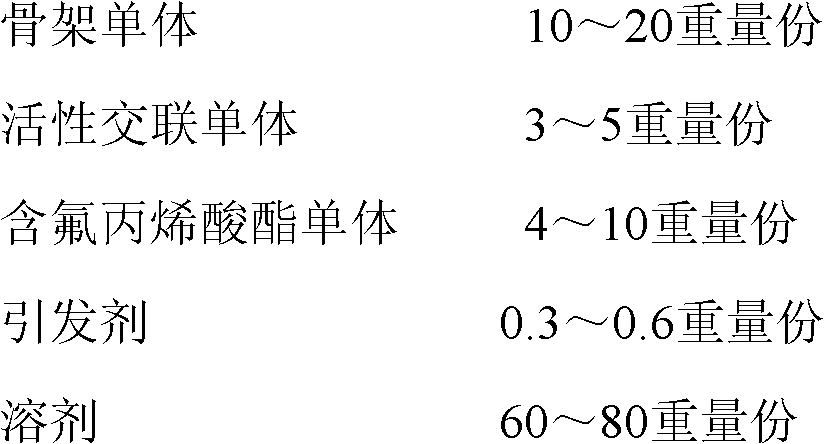

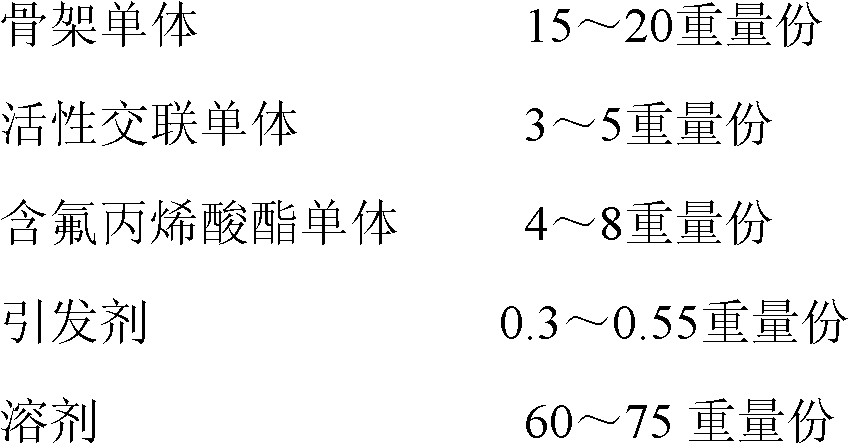

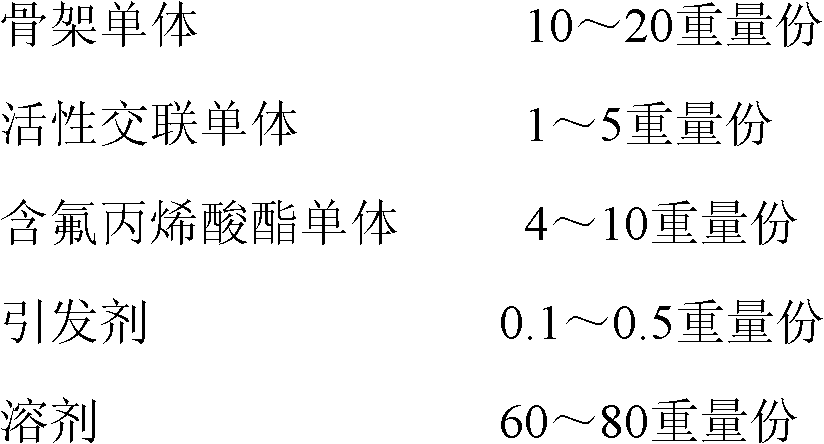

Method used

Image

Examples

Embodiment 1

[0039] The inorganic hollow or porous nanoparticles used are hollow porous nano silicon dioxide with a diameter of 500nm and a porosity of 80%. Under a negative pressure of -0.9MPa, soak 5g of hollow porous nano-silica in isopropanol, stop the adsorption after continuous adsorption for 1 hour, and use filter paper to blot excess small molecules on the particle surface. The adsorption capacity of hollow porous nano-silica to isopropanol is 2.5g / g.

[0040] Using the method of semi-continuous seed emulsion polymerization, raise the temperature of the water bath to 70-75 ° C, blow nitrogen, and add 6 g of methyl methacrylate, 8 g of butyl acrylate, 1 g of hydroxyethyl methacrylate, and persulfuric acid at a time at 300 rpm. A mixed solution of 0.1g of potassium and 40g of water is reacted for half an hour to synthesize a seed emulsion; continue to heat up to 80-85°C, and continuously add 2g of methyl methacrylate, 2g of butyl acrylate, and dodecafluoromethacrylate dropwise over 3...

Embodiment 2

[0043] The inorganic hollow or porous nano-particles used are porous nano-alumina with a diameter of 100-200nm and a porosity of 60%. Under a negative pressure of -0.5MPa, soak 4g of porous nano-alumina into simethicone oil, stop the adsorption after continuous adsorption for 3 hours, and use filter paper to absorb excess small molecules on the particle surface. The adsorption capacity of porous nano-alumina to simethicone is 1.6g / g. The fluoropolymer used is an aqueous dispersion of fluorine-containing acrylate ( 8740 porous surface protection agent), the solvent is water. The fluorine-containing acrylate aqueous dispersion belongs to cationic perfluoroalkyl methacrylic acid copolymer, has waterproof, oil-proof, and anti-fouling properties, and its solid content is 30wt%, and the surface energy of the coating film is 15mN / m. The contact angle was 115°.

[0044] 3g of porous nano-alumina adsorbed with simethicone, 2g of fluorine-containing acrylate aqueous dispersion and 2...

Embodiment 3

[0046] The inorganic hollow or porous nanoparticles used are hollow porous nano titanium dioxide with a diameter of 80-100nm and a porosity of 66%. Under a negative pressure of -0.6MPa, soak 4g of hollow porous nano-titanium dioxide into hexadecane, stop the adsorption after continuous adsorption for 5 hours, and use filter paper to dry up excess small molecules on the particle surface. The adsorption capacity of hollow porous nano titanium dioxide to hexadecane is 2g / g.

[0047] The fluorine-containing polymer adopted is self-made fluorine-containing acrylic resin, and the solvent is butyl acetate. The fluorine-containing acrylic resin adopts the method of free radical solution polymerization. First, the temperature of the solvent is raised to 70-75 ° C, nitrogen gas is passed, and 5 g of methyl methacrylate, 7 g of butyl acrylate, 4 g and 8 g of acrylic acid are continuously added dropwise for 2.5 to 3 hours. A mixed solution of pentafluorononyl methacrylate and 0.4 g of az...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com