Fermentation production process of Epothilone B

A technology of epothilone and production process, which is applied in the field of epothilone B fermentation production process, can solve the problems of high production cost of epothilone, difficulty in increasing the fermentation yield of epothilone, high cost of separation and purification of target products, etc. problem, achieve the effect of eliminating glucose inhibition effect and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

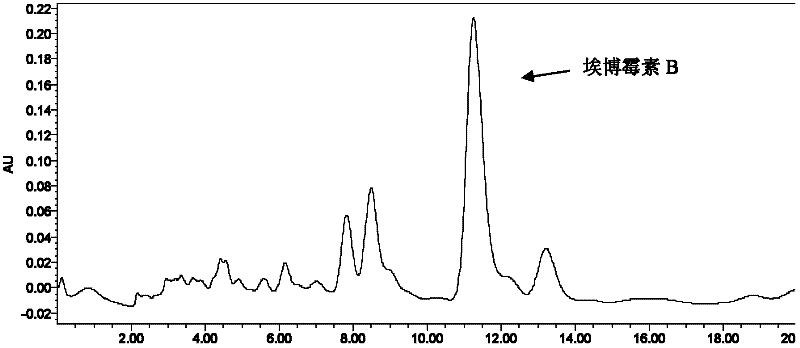

Image

Examples

Embodiment 1

[0030] The preparation of molecularly imprinted polymer and the fermentation of epothilone B include the following steps:

[0031] 1) Preparation of molecularly imprinted polymers

[0032] According to the following proportions: mix 1 mmol of epothilone B, 4 mmol of methacrylic acid, 20 mmol of ethylene glycol dimethacrylate, 10 mg of azobisisobutyrocyanide, and 3 ml of acetonitrile into a reaction tube, pass nitrogen and oxygen for 30 minutes, and Under the protection of nitrogen, the reaction tube was sealed, placed in a water bath at 50°C for 24 hours, and then polymerized in a water bath at 60°C for 12 hours to obtain a polymerization reaction product;

[0033] Crushing, grinding, and sieving the obtained reaction product to obtain polymer particles with a particle size of 40-60 μm;

[0034] After the obtained polymer particles were washed with water, they were extracted with a Soxhlet extractor in a mixed solution of acetic acid:methanol (volume ratio 1:9) for 48 hours, ...

Embodiment 2

[0049] The preparation of molecularly imprinted polymer and the fermentation of epothilone B include the following steps:

[0050] 1) Preparation of molecularly imprinted polymers

[0051] According to the following proportions: mix 1 mmol of epothilone B, 3 mmol of methacrylic acid, 25 mmol of ethylene glycol dimethacrylate, 10 mg of azobisisobutyronitrile, and 8 ml of methanol into a reaction tube, pass nitrogen and exhaust oxygen for 30 minutes, and Under the protection of nitrogen, the reaction tube was sealed, placed in a 45°C water bath for 24 hours of polymerization, and then polymerized in a 65°C water bath for 12 hours to obtain a polymerization reaction product;

[0052] Crushing, grinding, and sieving the obtained reaction product to obtain polymer particles with a particle size of 40-60 μm;

[0053] After the obtained polymer particles were washed with water, they were extracted with a Soxhlet extractor in a mixed solution of acetic acid:methanol (volume ratio 3:7...

Embodiment 3

[0065] The preparation of molecularly imprinted polymer and the fermentation of epothilone B include the following steps:

[0066] 1) Preparation of molecularly imprinted polymers

[0067] According to the following proportions: mix 1 mmol of epothilone B, 3.5 mmol of methacrylic acid, 30 mmol of ethylene glycol dimethacrylate, 5 mg of azobisisobutylcyanide, and 3 ml of acetonitrile into the reaction tube, pass nitrogen and oxygen for 30 minutes, Under the protection of nitrogen, the reaction tube was sealed, placed in a water bath at 50°C for 24 hours, and then polymerized in a water bath at 60°C for 12 hours to obtain a polymerization reaction product;

[0068] Crushing, grinding, and sieving the obtained reaction product to obtain polymer particles with a particle size of 40-60 μm;

[0069] After the obtained polymer particles were washed with water, they were extracted with a Soxhlet extractor in a mixed solution of acetic acid:methanol (volume ratio 3:7) for 48 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com