Polypropylene resin film for surface protection, and surface protective film

A technology of polypropylene and resin film, which is applied in the direction of synthetic resin layered products, film/sheet adhesives, layered products, etc., and can solve the problem of difficult lamination of transparent polypropylene sheets and insufficient rigidity of polypropylene films , easy to produce wrinkles and slack, etc., to achieve the effect of less white spots, excellent handling, and appropriate surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

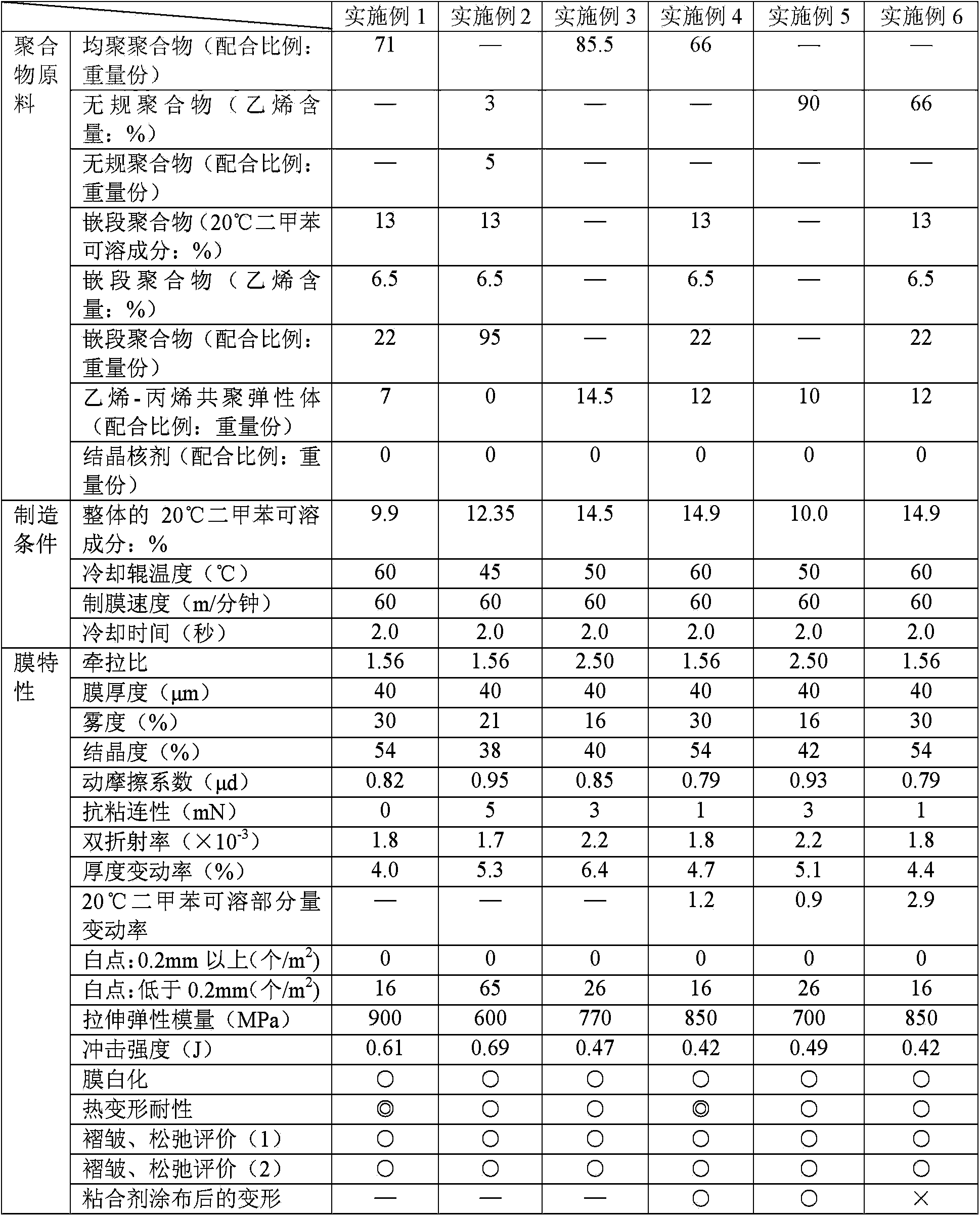

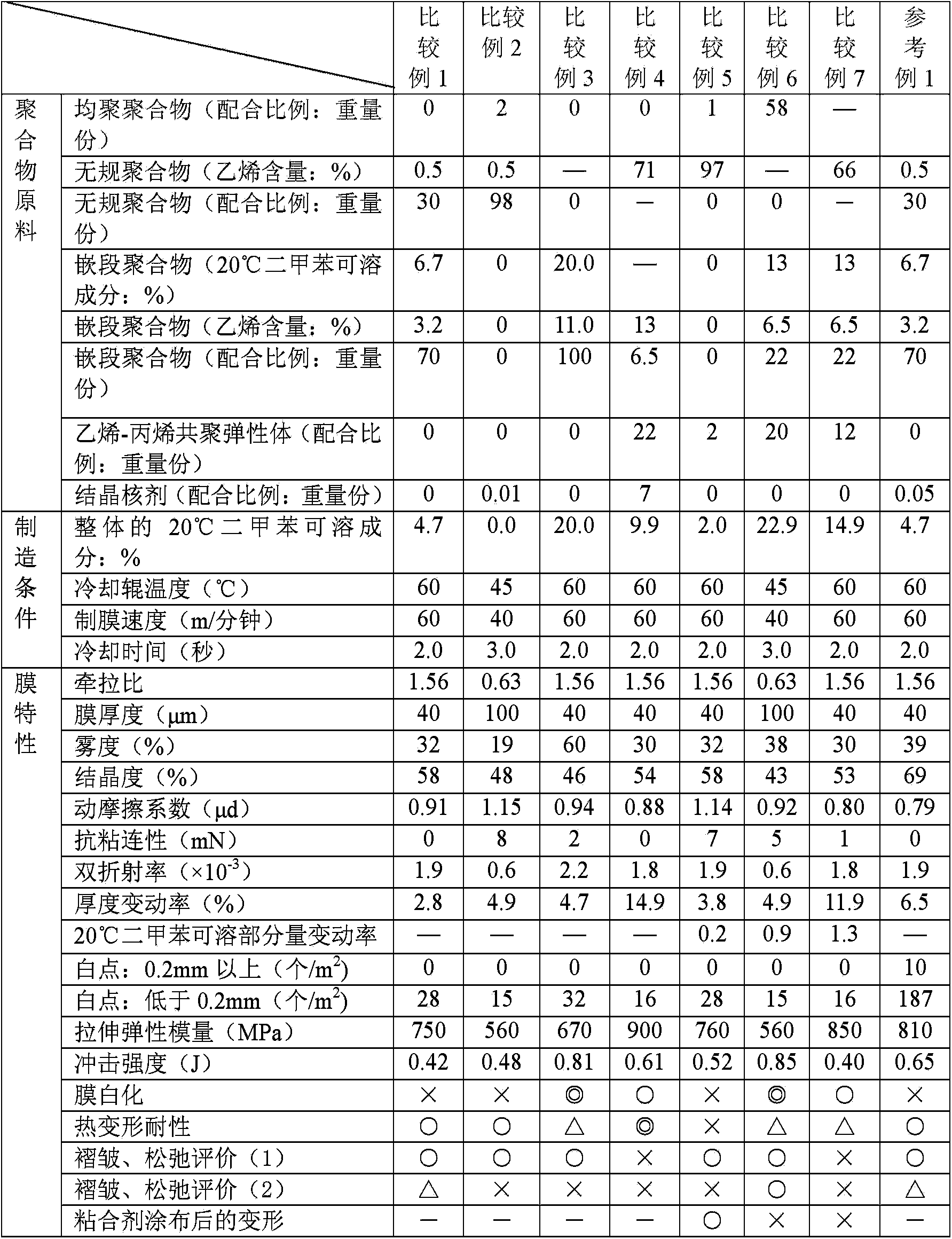

Examples

Embodiment 1

[0170] 69 parts by weight of a homopolypropylene resin (MFR=7), 22 parts by weight of a block copolymer polypropylene resin (MFR=2) with a rubber content of 13.0% and an ethylene content of 6.5%, an elastomer manufactured by Mitsui Chemicals, Ltd. (trade name: タフマ-P0480) 7 parts by weight and 2 parts by weight of the masterbatch resin are melt-extruded with a T-die film-making machine with a hot bolt type automatic thickness control function, and the masterbatch resin contains: made of acrylic acid An acrylate antioxidant composed of a homopolypropylene resin (MFR=7) containing 5% by weight of Sumilazer GS (manufactured by Sumitomo Chemical Co., Ltd.) of the ester antioxidant was cooled at a cooling roll temperature of 60° C. for 2.0 seconds (manufactured Film speed 60m / min), draw ratio of molten resin 1.56 (die lip gap: 0.5mm, die lip outlet molten resin speed: 4.8m / min, air gap: 8cm), air chamber wind pressure 10mmHg Under film conditions, an unstretched film with a thicknes...

Embodiment 2

[0173] 13.0% / 95 parts by weight of a block copolymerized polypropylene resin (MFR=2) with an ethylene content of 6.5%, 5 parts by weight of a random copolymerized polypropylene resin (MFR=7) with an ethylene content of 3.0%, the temperature of the set cooling roll is 45°C, Except for this, the polypropylene-type resin film of Example 2 was obtained by the method similar to Example 1. The results are shown in Table 1.

[0174] The polypropylene-based resin film obtained in this example had all of the properties shown in Table 1 good and was of high quality.

Embodiment 3

[0176] Homopolypropylene resin (MFR) containing 0.15% by mass of Ilugahouse 168 (manufactured by Ciba Seika Co., Ltd.) =7) 85.5 parts by weight, 14.5 parts by weight of an elastomer (trade name: タフマ-P0480) manufactured by Mitsui Chemicals Co., Ltd., the cooling roll temperature is set to 50° C., and the drawing ratio during drawing of the molten resin is 2.50 (die lip The polypropylene-based resin film of Example 3 was obtained in the same manner as in Example 1 except that the gap: 0.8 mm, the velocity of molten resin at the lip outlet: 3.0 m / min, and the air gap: 8 cm). The results are shown in Table 1.

[0177] The polypropylene-based resin film obtained in this example had properties equivalent to those of the polypropylene-based resin film obtained in Example 1, and was of high quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com