Bacillus licheniformis and applications thereof

A technology of Bacillus licheniformis and strains, applied in the directions of bacteria, microorganisms, biochemical equipment and methods, etc., can solve the problems of low production efficiency, long cycle of 72 hours, long production cycle of Bacillus licheniformis, etc., and achieves high production efficiency and fermentation. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Isolation and screening of bacterial strains of the present invention

[0036] Select a variety of soybean sauces produced in China, take 1g each into a sterilized test tube, add 9mL of sterile water, seal with a cotton plug, shake for 2min, then put it in a water bath, heat at 70°C for 10min, and then let it stand for 30min. After cooling, absorb 0.1 mL of the supernatant and dilute 10 2 and 10 3 times, respectively take 0.2mL, spread LB plate (sodium glutamate 10g / L, peptone 10g / L, yeast powder 5g / L, sodium chloride 10g / L, agar powder 15g / L, pH7.2), 37 Cultivate at ℃ for 48 hours to observe the results, select a single colony that is emulsion-like and capable of drawing on LB medium, and insert it into fresh LB liquid seed medium (peptone 10g / L, yeast powder 5g / L, sodium chloride 10g / L, pH7. 2), after 12 hours of culture on a shaker at 37°C, inoculate 2% of the inoculum into 250mL shake flasks (sodium glutamate 50g / L, glucose 50g / L, citric acid Sodium...

Embodiment 2

[0037] Embodiment 2: the identification of bacterial strain of the present invention

[0038] Physiological and biochemical identification

[0039] The Bacillus licheniformis bacterial strain provided by the invention is straight rod-shaped and Gram-staining positive. On LB solid medium, the colonies are round, dry, opaque, spreading, ragged, and hairy. The optimum growth temperature is 30-37℃, and the suitable pH is 6.8-7.2. The contact enzyme test was positive, the nitrate test was positive, the citrate test was positive, and the gelatin liquefaction test was positive.

[0040] Identification of Bacterial Species Using 16S rRNA Gene Sequence Analysis

[0041] The total DNA of strain P-104 was extracted by a bacterial genome extraction kit, and the 16S rRNA gene PCR amplification was carried out with universal primers (27f: AGAGTTTGATCCTGGCTCAG) and (1492r: GGTTACCTTGTTACGACTT). The PCR program was: 94°C pre-denaturation for 5 min; 94°C denaturation for 45 s, 55°C anneali...

Embodiment 3

[0042] Embodiment 3: Qualitative and quantitative analysis of polymer products produced by bacterial strain P-104 of the present invention

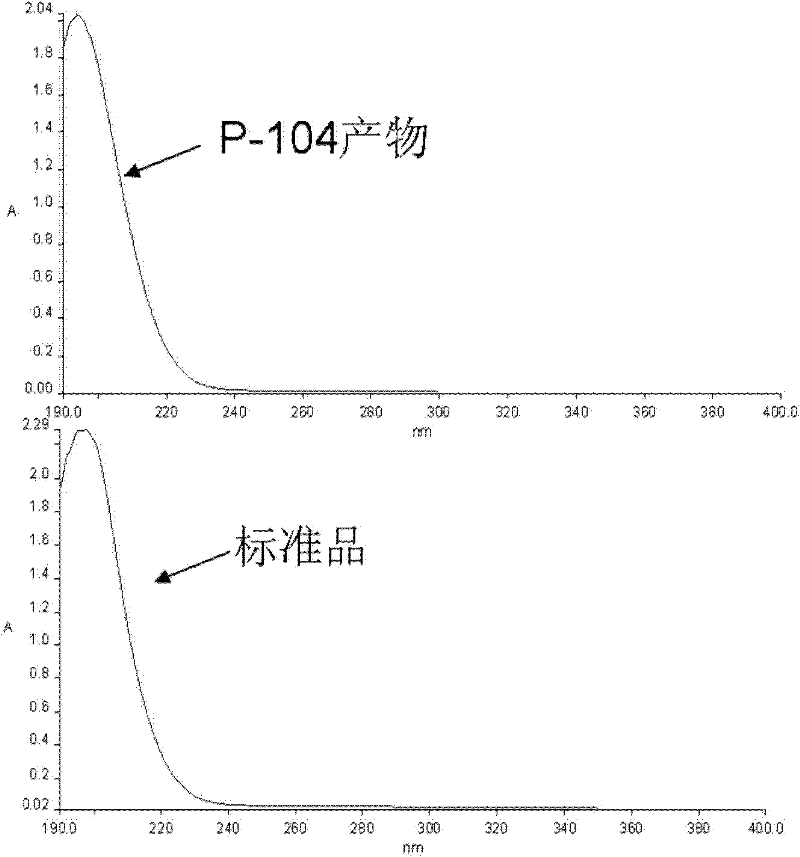

[0043] Using ultraviolet spectrum scanning and infrared spectrum analysis, and comparing with the spectrogram of γ-PGA standard product, it shows that the high molecular product obtained by strain P-104 fermentation is γ-PGA.

[0044] The polymer product produced by bacterial strain P-104 of the present invention is hydrolyzed under acidic conditions, and the hydrolyzed product is subjected to qualitative and quantitative analysis by HPLC. The chromatographic column used is Brava C18-BDS, and the mobile phase is 10mmol / LKH 2 PO 4 Add 5.0% methanol (adjust the pH value to 2.5 with phosphoric acid, filter, and degas by ultrasonic), the flow rate is 1mL / min, the ultraviolet detection wavelength is 210nm, and the glutamic acid standard is used as a qualitative and quantitative standard. γ-PGA concentration = glutamic acid concentration after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com