Plastered insulated compound wall body with nets on both sides

A thermal insulation composite and wall technology, which is applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of increasing the average heat transfer coefficient of the wall, increasing the construction workload, and the low heat transfer coefficient of the wall, so as to increase energy saving and heat preservation Good effect, saving welding material consumption, good effect of gas insulation and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

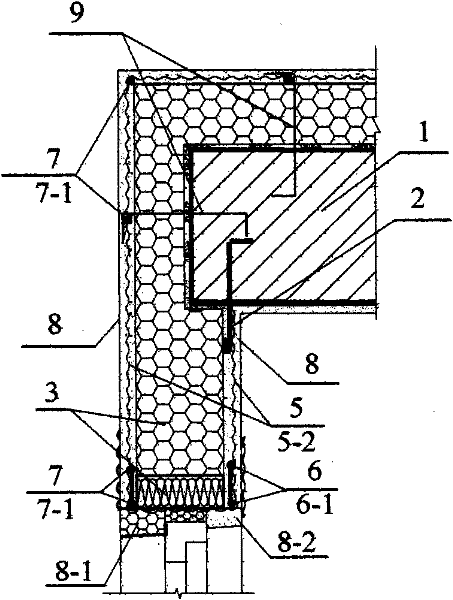

[0079] Embodiment one: see Figure 1 to Figure 9 , Figure 11 , Figure 13 , a thermal insulation composite wall with net plastering on both sides of the present embodiment is composed of a load-bearing member 1 of the building main structure, a core layer 3, a mesh tensile material 5, an indoor steel bar 6, an outdoor steel bar 7, a protective layer 8, The outer protective layer 8-1 of the door and window of the opening, the inner protective layer 8-2 of the door and window of the opening, the supporting cantilever beam or plate 1-5 and the inner and outer pull wires 9; the load-bearing member 1 of the main structure of the building is a beam (including the foundation Beams), plates (including base plates), columns, load-bearing walls; the outdoor reinforcement 7 includes outdoor vertical reinforcement 7-1, outdoor horizontal reinforcement 7-2; the indoor reinforcement 6 includes indoor vertical reinforcement 6-1, indoor Horizontal steel bar 6-2; the core layer 3 is polymer...

Embodiment 2

[0096] Embodiment two: see Figure 10 , the difference between this embodiment and Embodiment 1 is: the supporting cantilever beam or plate 1-5 is a steel truss cantilever beam, and the steel truss cantilever beam has a diagonal bar to bear the tension; or also use cement polymer Mortar protects the steel truss cantilever beams from corrosion; the opening is a heat-insulating bridge opening; or the opening core layer 3 has an opening protection layer 8-3 of cement mortar or fine stone concrete plastering layer, and the core layer 3 It is connected with the opening protective layer 8-3, and the doors and windows are installed on the opening protective layer 8-3 to form an opening with a thermal bridge.

[0097] This embodiment is proposed in order to solve the second problem existing in the patent technology disclosed by the inventor of this patent application mentioned in the background technology.

[0098] The key difference between this embodiment and the disclosed technolo...

Embodiment 3

[0106] Embodiment three: see image 3 , Figure 4 , Figure 11 , Figure 12 The difference between this embodiment and Embodiment 1 or 2 is: the core layer 3 is all installed on the outer side of the load-bearing member 1 of the main building structure to form an externally hung thermal insulation composite wall; the opening is a thermal insulation bridge A hole; or the hole is a hole with a thermal bridge.

[0107] The key difference between this embodiment and the disclosed technology is that this embodiment provides the structure of an externally hung thermal insulation composite wall.

[0108] This embodiment is proposed in order to solve the third problem existing in the patent technology disclosed by the inventor of this patent application mentioned in the background technology.

[0109] The thickness of the core layer of the external-hanging thermal insulation composite wall is the same in all parts of the building, and a large core layer can be installed according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com