Solid degradation agent for producing polypropylene fiber with high fusion index, and preparation method thereof

A technology of melt index and degrading agent, applied in the direction of fiber chemical characteristics, single-component polyolefin rayon, rayon manufacturing, etc., can solve the problems affecting the quality of continuous products, unstable melt index, poor uniformity, etc. Achieve the effect of improving operational safety, high effective equivalent, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

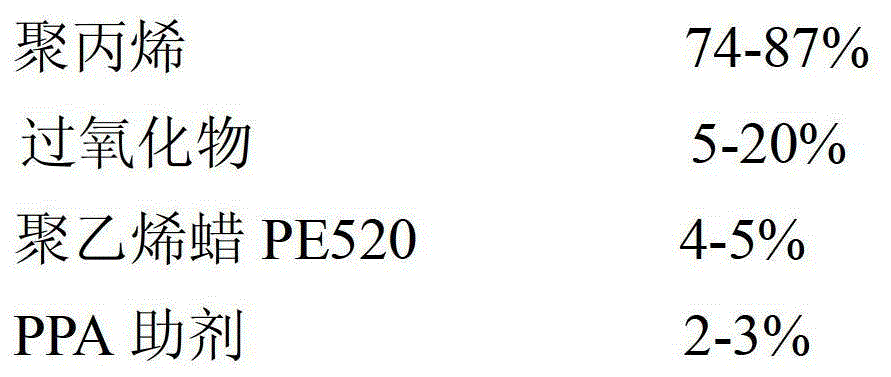

[0041] A kind of solid degradation agent is made up of following components by weight percentage:

[0042] Polypropylene T30S powder 87kg

[0043] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane 5kg

[0044] Polyethylene wax PE520 5kg

[0045] FX5911 3kg

[0046] Among them, the melt index of polypropylene T30S powder is 3-5g / 10min (230°C, 2.16kg).

[0047] Put the above raw materials into the mixer according to the ratio and mix them for 4 minutes, then send the mixture into the twin-screw extruder, melt extrusion and granulation at 120°C, and the extruded product is melted and granulated to obtain a solid degradation agent.

Embodiment 2

[0049] A kind of solid degradation agent is made up of following components by weight percentage:

[0050] Polypropylene T30S powder 83kg

[0051] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane 10kg

[0052] Polyethylene wax PE520 5kg

[0053] FX5911 2kg

[0054] Among them, the melt index of polypropylene T30S powder is 3-5g / 10min (230°C, 2.16kg).

[0055] Put the above raw materials into the mixer according to the ratio and mix them for 4 minutes, then send the mixture into the twin-screw extruder, melt extrusion and granulation at 120°C, and the extruded product is melted and granulated to obtain a solid degradation agent.

Embodiment 3

[0057] A kind of solid degradation agent is made up of following components by weight percentage:

[0058] Polypropylene T30S powder 78kg

[0059] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane 15kg

[0060] Polyethylene wax PE520 5kg

[0061] FX5911 2kg

[0062] Among them, the melt index of polypropylene T30S powder is 3-5g / 10min (230°C, 2.16kg).

[0063] Put the above raw materials into the mixer according to the ratio and mix them for 4 minutes, then send the mixture into the twin-screw extruder, melt extrusion and granulation at 120°C, and the extruded product is melted and granulated to obtain a solid degradation agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com