Environment-friendly porcelain tile made from sewage squeezing mud

A technology for pressing mud and porcelain tiles, applied in the field of ceramic tiles, can solve the problems of paper scraps and oil stains that cannot be completely removed, limited composition and performance, and limited application scope, and achieves the promotion of recycling, wide use range and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

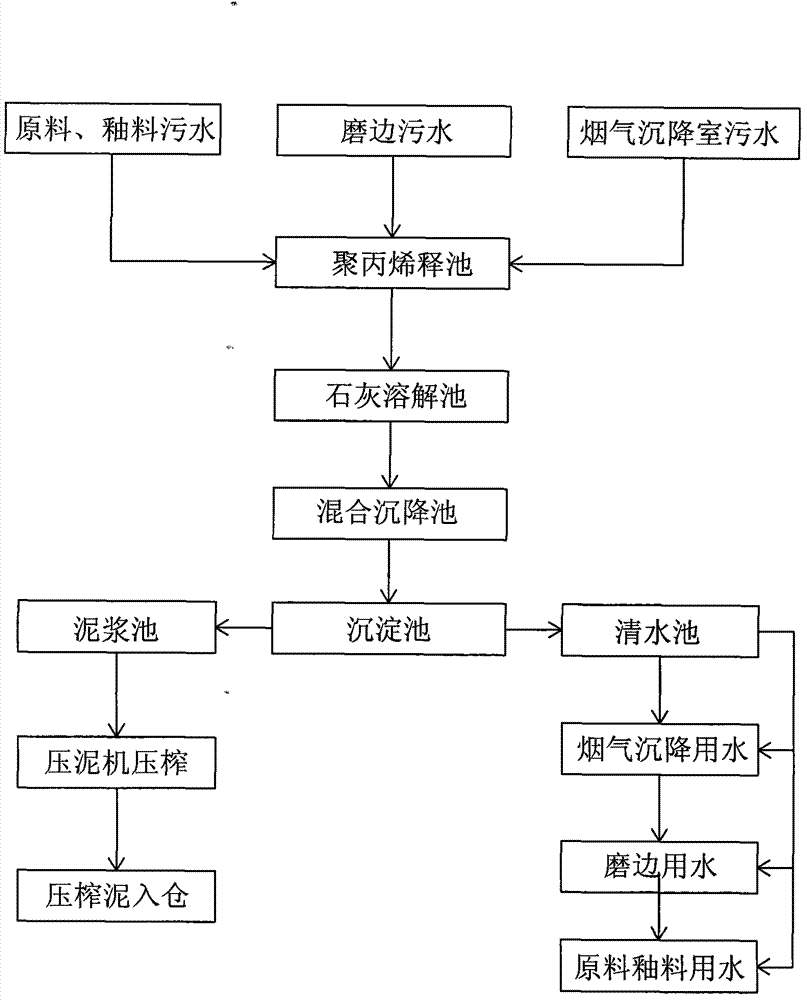

[0036] figure 1 It is a process flow chart of extracting pressed mud in the present invention.

[0037] exist figure 1 In the process of pressing mud preparation: through the design of special ditches, raw material sewage, glaze sewage, edging sewage, and flue gas settling room sewage are drained to the sewage pool, and then the sewage enters the polyacrylamide dilution pool and the lime melting pool to carry out sewage treatment. Purify and adjust the treatment to make the pH value of the sewage reach 8.5-9.0, then enter the mixed sedimentation tank, and settle in the sedimentation tank to make the solid mud gradually settle and separate from the water. The sedimentation tank enters the mud and clean water and returns to the factory for recycling as production water , the precipitated mud is squeezed by the mud press and put into the warehouse, which is used as the raw material of the environmentally friendly porcelain tiles.

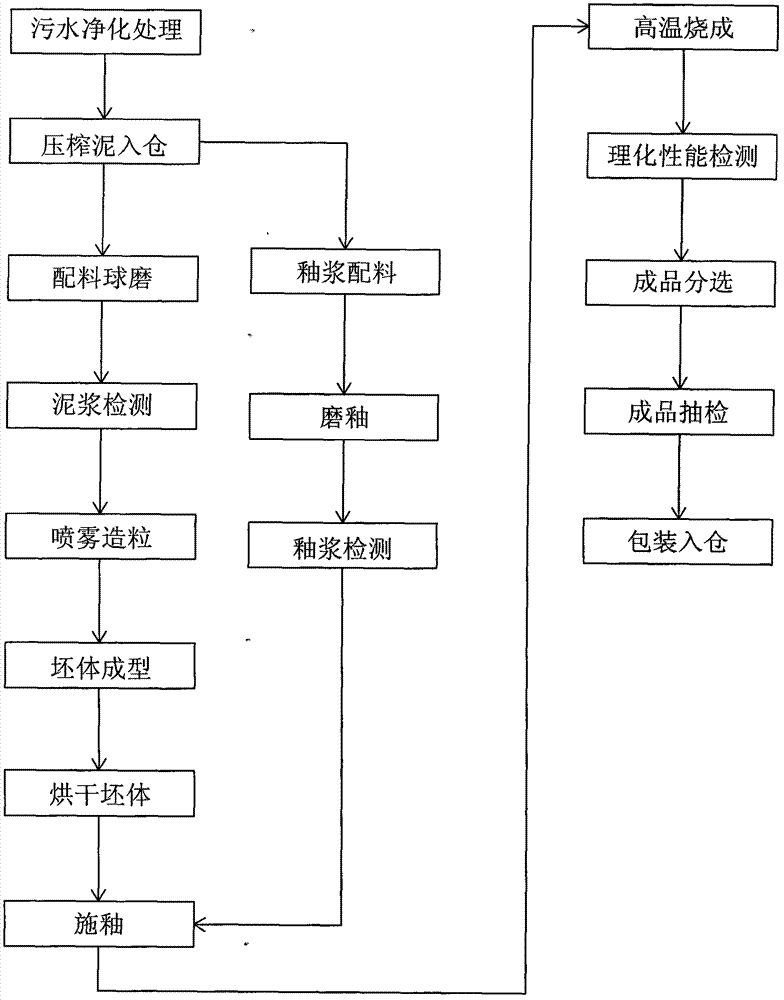

[0038] figure 2 It is a production process f...

Embodiment 2

[0053] figure 1 It is a process flow chart of extracting pressed mud in the present invention.

[0054] exist figure 1 In the process of pressing mud preparation: through the design of special ditches, raw material sewage, glaze sewage, edging sewage, and flue gas settling room sewage are drained to the sewage pool, and then the sewage enters the polyacrylamide dilution pool and the lime melting pool to carry out sewage treatment. Purify and adjust the treatment to make the pH value of the sewage reach 8.5, then enter the mixed sedimentation tank, and settle in the sedimentation tank to make the solid mud gradually settle and separate from the water. After being squeezed by a mud press, the mud is put into the warehouse and used as a raw material for environmentally friendly porcelain tiles.

[0055] figure 2 It is a production process flow chart of the present invention.

[0056] exist figure 2 In the process, after the sewage is purified, the squeezed mud is extracted...

Embodiment 3

[0065] figure 1 It is a process flow chart of extracting pressed mud in the present invention.

[0066] exist figure 1 In the process of pressing mud preparation: through the design of special ditches, raw material sewage, glaze sewage, edging sewage, and flue gas settling room sewage are drained to the sewage pool, and then the sewage enters the polyacrylamide dilution pool and the lime melting pool to carry out sewage treatment. Purification and adjustment treatment, after the pH value of the sewage reaches 9.0, it enters the mixed sedimentation tank, and the solid mud is gradually precipitated and separated from the water after being settled in the sedimentation tank. After being squeezed by a mud press, the mud is put into the warehouse and used as a raw material for environmentally friendly porcelain tiles.

[0067] figure 2 It is a production process flow chart of the present invention.

[0068] exist figure 2 In the process, after the sewage is purified, the sque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com