Preparation method of casting aluminum-coated magnesium alloy composite cast ingot

An aluminum-magnesium alloy-clad and composite ingot technology is applied in the field of casting an aluminum-magnesium alloy-clad composite ingot, which can solve the problems of poor interface bonding ability and low yield, and achieve a small thickness of the coating layer and the ability to fill the mold. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

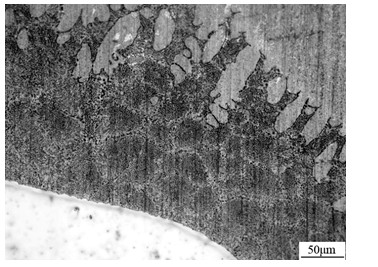

Embodiment 1

[0017] Grade and composition of cladding aluminum alloy:

[0018] 1060 pure aluminum plate, its mass fraction: contains Fe 0.21%, Si 0.09%, Cu 0.01%, Mn 0.01%, Mg 0.01%, Zn 0.02%, Ti 0.17%, and the rest is Al.

[0019] Grade and composition of core magnesium alloy:

[0020] AZ31 magnesium alloy ingot, its mass fraction: Al 3.06%, Zn 1.18%, Mn 0.47%, Si 0.016%, Cu ≤0.002%, Fe ≤0.002%, Ni ≤0.0001%, and the rest is Mg.

[0021] Specific steps:

[0022] (1) The 1060 pure aluminum plate with a thickness of 1.6 mm is continuously welded by argon arc welding into a prefabricated aluminum plate box with a size of 300 mm×150 mm×20 mm and one side opening;

[0023] (2) Grind the embossed part of the welding interface with a grinding wheel to make the sides of the aluminum plate box smooth; use 5% NaOH solution, 5% hydrochloric acid solution and absolute ethanol to clean the cavity of the aluminum plate box in order to remove surface oil and oxides Then place it in a resistance oven w...

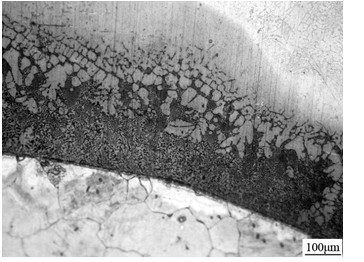

Embodiment 2

[0027] Grade and composition of cladding aluminum alloy:

[0028] 1060 pure aluminum plate, its mass fraction: contains Fe 0.21%, Si 0.09%, Cu 0.01%, Mn 0.01%, Mg 0.01%, Zn 0.02%, Ti 0.17%, and the rest is Al.

[0029] Core material magnesium alloy composition:

[0030] Mg-2.0Mn-0.6Ca alloy, its mass fraction: contains Mn 2.0%, Ca 0.6%, and the rest is Mg.

[0031] Specific steps:

[0032] (1) The 1060 pure aluminum plate with a thickness of 1.6 mm is continuously welded by argon arc welding into a prefabricated aluminum plate box with a size of 300 mm×150 mm×20 mm and one side opening;

[0033] (2) Grind the embossed part of the welding interface with a grinding wheel to make the sides of the aluminum plate box smooth; use 5% NaOH solution, 5% hydrochloric acid solution and absolute ethanol to clean the cavity of the aluminum plate box in sequence to remove surface oil and oxides Place in a resistance oven with a protective atmosphere for preheating at 200°C;

[0034] (3)...

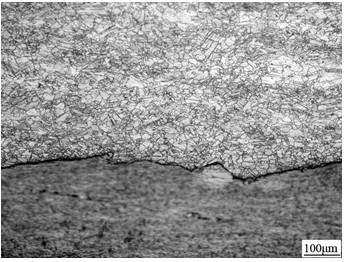

Embodiment 3

[0036] Grade and composition of cladding aluminum alloy:

[0037] 1060 pure aluminum plate, its mass fraction: contains Fe 0.21%, Si 0.09%, Cu 0.01%, Mn 0.01%, Mg 0.01%, Zn 0.02%, Ti 0.17%, and the rest is Al.

[0038] Core material magnesium alloy composition:

[0039] Mg-12Li alloy, its mass fraction: Li 12%, the rest is Mg.

[0040] Specific steps:

[0041] (1) The 1060 pure aluminum plate with a thickness of 1.6 mm is continuously welded by argon arc welding into a prefabricated aluminum plate box with a size of 300 mm×150 mm×20 mm and one side opening;

[0042] (2) Grind the embossed part of the welding interface with a grinding wheel to make the sides of the aluminum plate box smooth; use 5% NaOH solution, 5% hydrochloric acid solution and absolute ethanol to clean the cavity of the aluminum plate box in sequence to remove surface oil and oxides Place in a resistance oven with a protective atmosphere for preheating at 200°C;

[0043] (3) The materials used in the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com