GaN-based LED epitaxial wafer and growing method thereof

An LED epitaxial wafer, n-type technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems affecting crystal quality, reducing luminous efficiency and antistatic ability, etc., to expand current and improve antistatic ability. and leakage, the effect of improving the quality of crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

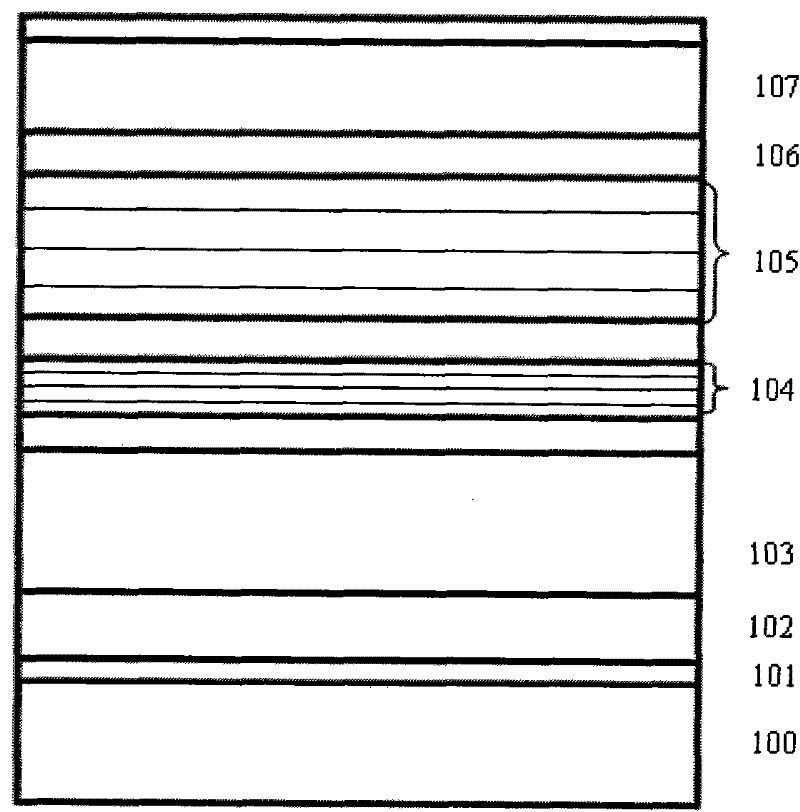

[0040] Embodiment 1 uses the MOCVD method to grow sequentially from bottom to top:

[0041] 1. Put the sapphire substrate with (0001) crystal orientation into the reaction chamber, and then 2 Heating to 900° C. under atmosphere and baking for 20 minutes to purify the substrate at high temperature.

[0042] 2. Lower the temperature to 500°C to grow a low-temperature GaN buffer layer with a thickness of 15nm.

[0043] 3. Grow non-doped GaN with a thickness of 1 μm at 900°C.

[0044] 4. Grow n-type GaN with a thickness of 1 μm at 900°C.

[0045] 5. An n-type GaN defect blocking layer is grown for one cycle at 900°C. This layer structure from bottom to top is as follows:

[0046] The first layer: a thickness of 350nm, is an n-type GaN layer doped with Si, and the doping concentration of Si is 1×10 16 cm -3 ;

[0047] The second layer: a thickness of 350nm, is an n-type GaN layer doped with Si, and the doping concentration of Si is 3×10 18 cm -3 ;

[0048] The third layer...

Embodiment 2

[0056] Embodiment 2 uses the MOCVD method to grow sequentially from bottom to top:

[0057] Except step 5, other steps are as shown in embodiment 1

[0058] 5. N-type Al grown for one cycle at 900°C x Ga 1-x N defect blocking layer, where x=0.15. This layer structure from bottom to top is as follows:

[0059] The first layer: 350nm thick, n-type Al doped with Si 0.15 Ga 0.85 N layer, the doping concentration of Si is 1×10 16 cm -3 ;

[0060] Second layer: 350nm thick, n-type Al doped with Si 0.15 Ga 0.85 N layer, the doping concentration of Si is 3×10 18 cm -3 ;

[0061] The third layer: 350nm thick, n-type Al doped with Si 0.15 Ga 0.85 N layer, the doping concentration of Si is 1×10 16 cm -3 .

[0062] The epitaxial wafer obtained in this embodiment is made into 300×300 μm according to the standard chip process 2 A chip with ITO as the transparent electrode. After testing, its 4000V (Human Body Model) ESD reached 95%, and its brightness reached 16mW.

Embodiment 3

[0063] Embodiment 3 uses the MOCVD method to grow sequentially from bottom to top:

[0064] 1. Put the sapphire substrate with (0001) crystal orientation into the reaction chamber, and then 2 Heating to 900° C. under atmosphere and baking for 20 minutes to purify the substrate at high temperature.

[0065] 2. Lower the temperature to 600°C to grow a low-temperature GaN buffer layer with a thickness of 40nm.

[0066] 3. Grow non-doped GaN with a thickness of 3 μm at 1200°C.

[0067] 4. Grow n-type GaN with a thickness of 3 μm at 1200°C.

[0068] 5. Grow the n-type GaN defect blocking layer at 1200° C. for 20 cycles. This layer structure from bottom to top is as follows:

[0069] The first layer: with a thickness of 3nm, it is an n-type GaN layer doped with Si, and the doping concentration of Si is 5×10 18 cm -3 ;

[0070] The second layer: with a thickness of 3nm, it is an n-type GaN layer doped with Si, and the doping concentration of Si is 2×10 20 cm -3 ;

[0071] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com