Method for preparing high-voltage electrophoresis reagent acetone

A high-voltage electrophoresis and acetone technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems that the technical indicators and performance cannot meet the glass passivation process requirements of CMOS silicon rectifier devices, and achieve apparent conductance and electrophoretic flow. The effect of easy adjustment of degree, stable reverse electrical performance and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

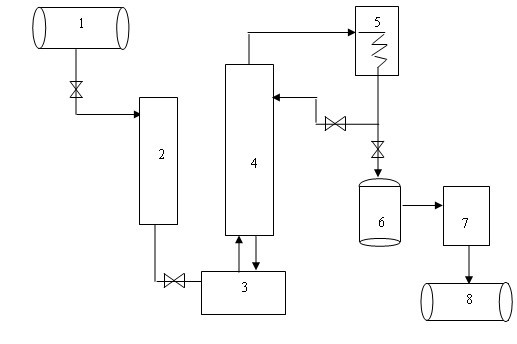

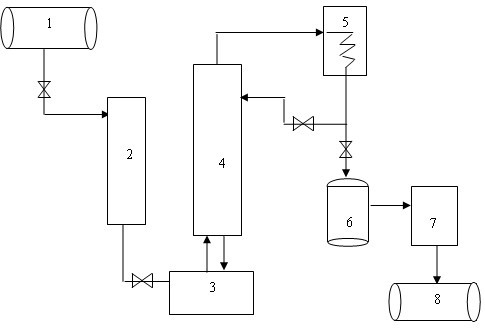

[0013] Embodiment: (1) The raw material acetone in the raw material storage tank is passed through a dry glass chromatography column for adsorption treatment, the upper section of the chromatography column is equipped with activated 3A molecular sieve, and the middle section is equipped with anhydrous potassium carbonate (analytical pure), The lower section contains activated 3A molecular sieves. The height ratio of the three sections is approximately equal. (The column capacity and 3A molecular sieve particle size are determined according to the processing requirements). Collect the effluent acetone from the chromatography column for G.C analysis and chemical analysis. Moisture content ≤0.3%, acidity or alkalinity ≤0.05mmol / 100g.

[0014] (2) Take 2500ml of acetone that has passed the above inspection and transfer it into a 3000ml dry still, and add about 200g of activated 3A molecular sieve. Install the packed distillation column, and connect the condenser of the packed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com