Oil-resistant high-temperature compression fatigue-resistant chloroprene rubber composition

A technology of neoprene and composition, applied to springs made of plastic materials, mechanical equipment, low internal friction springs, etc., can solve the problems of natural rubber such as narrow high temperature resistance range, poor oil resistance, and limited shock absorber applications , to achieve the effects of easy procurement, excellent fatigue resistance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

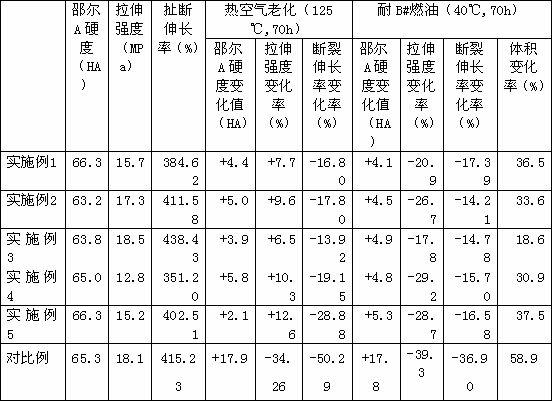

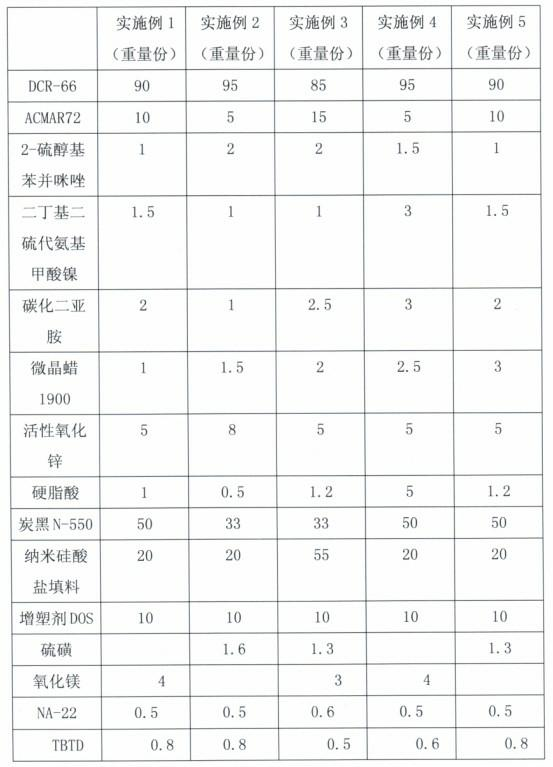

[0023] A neoprene rubber composition composed of the raw materials listed in the following table:

[0024]

[0025] The preparation method of the above-mentioned chloroprene rubber composition made into the shock-absorbing material used on the shock absorber of the automobile engine is: putting the chloroprene rubber and the acrylic rubber into an internal mixer at the same time, adding 2-mercaptobenzimidazole, two Nickel butyl dithiocarbamate, carbodiimide, microcrystalline wax 1900, activated zinc oxide, stearic acid, carbon black N-550, nano silicate filler, plasticizer DOS, open the internal mixer to mix Mix for 5 minutes, and ensure the temperature is below 65 degrees. Put the mixed rubber on a 6-inch open mill and make two triangle bags, then put it in the cold machine of the internal mixer, add sulfur, magnesium oxide, NA Keep the temperature of -22 and TBTD above 45 degrees and below 65 degrees. The mixing time is 3 minutes, and then take the two thin-thin triangle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com