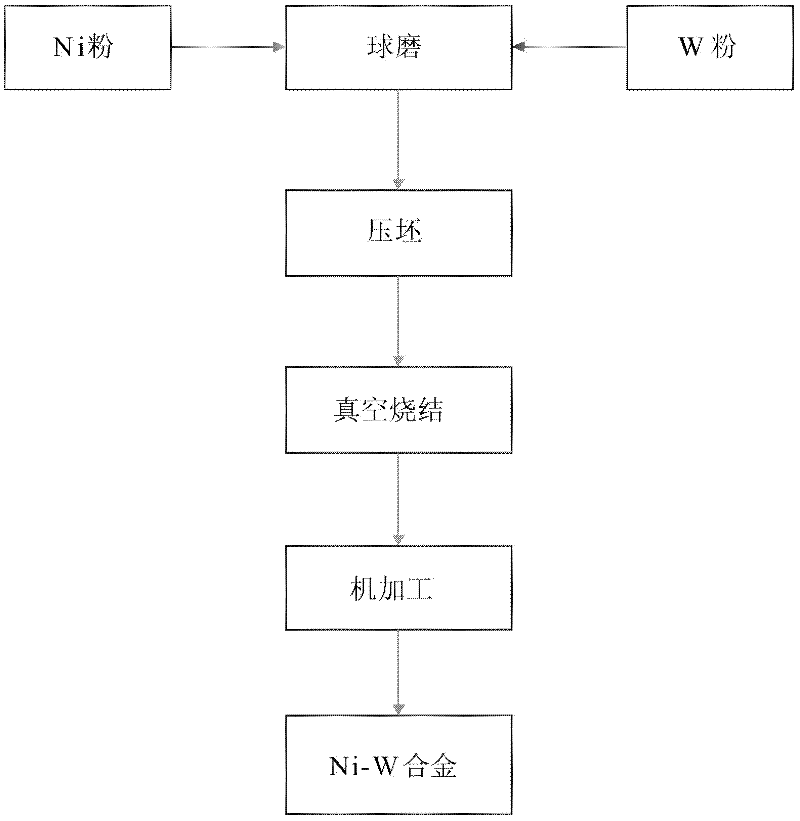

Method for preparing Ni-W alloy by vacuum sintering

A vacuum sintering and alloying technology, which is applied in the field of vacuum sintering to prepare Ni-W alloys, can solve the problems of high cost and low density of Ni-W alloys, and achieve the effects of easy implementation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

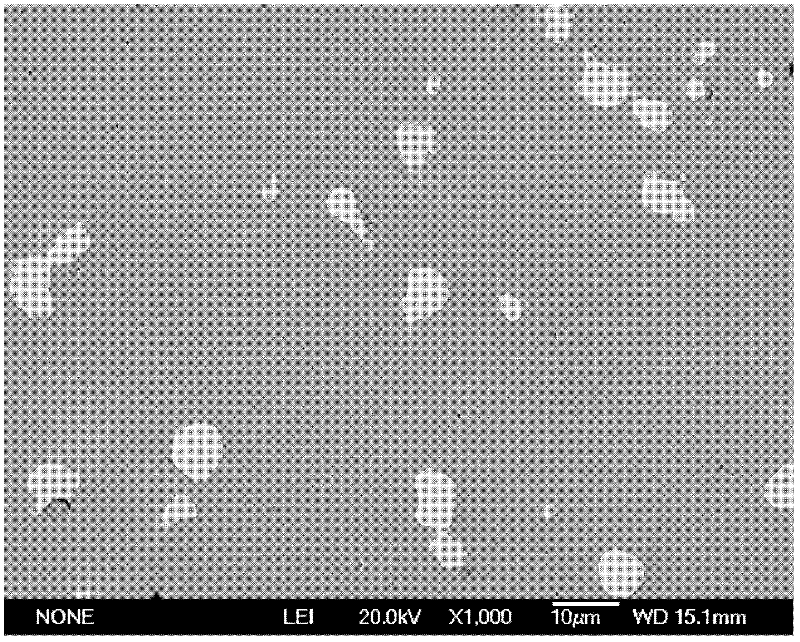

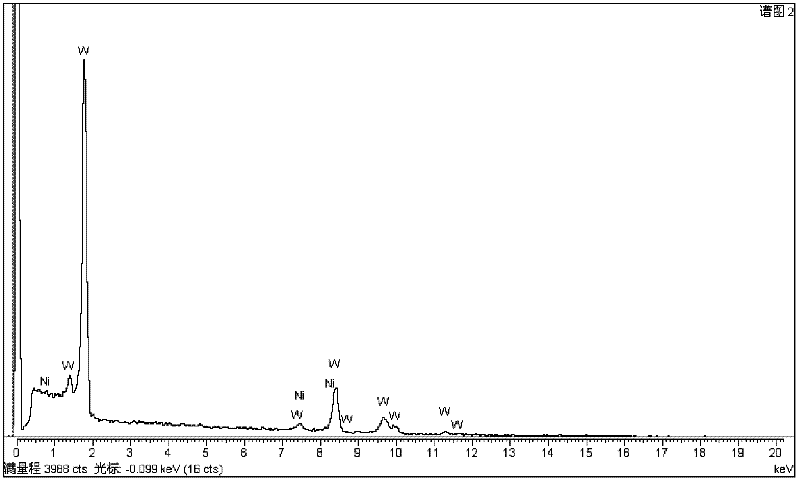

Embodiment 1

[0037] According to the Ni-W alloy chemical composition mass percentage Ni: W=70%: 30%, take by weighing the Ni powder and the particle diameter of 40~50 μ m, purity not less than 99.9%, oxygen content being 800~1000ppm respectively. 6~10μm, purity not less than 99.9%, W powder with oxygen content of 500~800ppm; mix the weighed Ni powder and W powder and put them into the ball mill tank, in order to balance the cold welding and fracture of the powder in the ball mill , add 4% dehydrated alcohol of the total mass of mixed powder in the ball mill as a process control agent, select WC balls as grinding balls, select the ball-milling ratio as 15:1, and then seal the ball milling tank for ball milling; the ball milling time is 24 hours , the speed of the ball milling tank is 200r / min; the mixed powder of nickel powder and tungsten powder after ball milling is molded, the pressure is 80MPa, and the pressure is kept for 15s; then the pressed billet is placed in the vacuum sintering fu...

Embodiment 2

[0039] According to the ratio of Ni-W alloy chemical composition mass percentage Ni: W=75%: 25%, take the Ni powder and particle diameter of 40~50 μ m, purity not less than 99.9%, and oxygen content to be 800~1000ppm respectively in particle diameter: 6~10μm, purity not less than 99.9%, W powder with oxygen content of 500~800ppm; mix the weighed Ni powder and W powder and put them into the ball mill tank, in order to balance the cold welding and fracture of the powder in the ball mill In the ball mill, add 5% dehydrated alcohol of the total mass of the mixed powder as a process control agent, select WC balls as the grinding balls, select the ball-milling ratio as 20:1, and then seal the ball milling tank for ball milling; the ball milling time is 48 hours , the speed of the ball milling tank is 200r / min; the mixed powder of nickel powder and tungsten powder after ball milling is molded, the pressure is 60MPa, and the pressure is kept for 20s; then the pressed billet is placed i...

Embodiment 3

[0041] According to the ratio of Ni-W alloy chemical composition mass percentage Ni: W=80%: 20%, take by weighing the Ni powder and particle diameter of 40~50 μ m, purity not less than 99.9%, oxygen content being 800~1000ppm respectively. 6~10μm, purity not less than 99.9%, W powder with oxygen content of 500~800ppm; mix the weighed Ni powder and W powder and put them into the ball mill tank, in order to balance the cold welding and fracture of the powder in the ball mill , add 2% dehydrated alcohol of the total mass of mixed powder in the ball mill as a process control agent, select WC balls as grinding balls, select the ball-milling ratio as 10:1, and then seal the ball milling tank for ball milling; the ball milling time is 72 hours , the speed of the ball milling tank is 200r / min; the mixed powder of nickel powder and tungsten powder after ball milling is molded, the pressure is 70MPa, and the pressure is kept for 10s; then the pressed billet is placed in the vacuum sinteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com