Preparation method of CdTe/CdS/SiO2 composite fluorescent nanoparticle

A technology of nanoparticles and composite fluorescence, which is applied in the field of composite fluorescent nanoparticles, can solve the problems of interfering with the quantum yield of quantum dots, the decrease of quantum yield, and the destruction of crystal structure, etc., and achieve the advantages of convenient operation, small particle size, and high quantum yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]45 mg of tellurium powder and 120 mg of sodium borohydride were added to the syringe, and then 3 mL of ultrapure water was added thereto. After reacting at low temperature for 12 hours, the black tellurium powder disappeared and white sodium borate crystals were produced. Clear NaHTe solution.

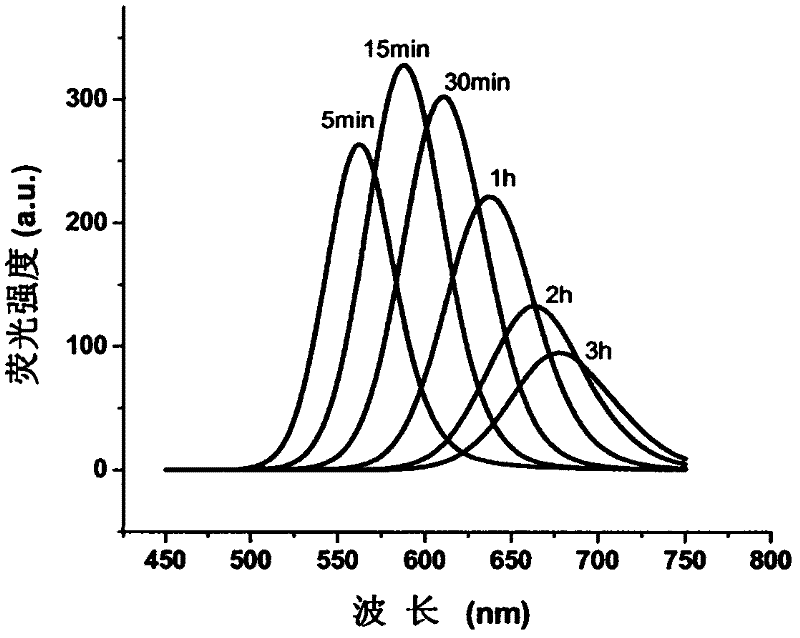

[0029] Weigh 0.4567g 2CdCl 2 ·5H 2 Dissolve O in 250mL ultrapure water, add 251μL mercaptopropionic acid (MPA), use 1M NaOH solution to adjust its pH value to 10.0, and pass N under vigorous stirring. 2 Deoxygenation was performed for 30 min, and then the newly prepared NaHTe solution was quickly added to obtain the precursor solution. The precursor solution was boiled and refluxed at 100° C. for 30 minutes to prepare the CdTe precursor. After cooling to room temperature, adjust its pH value to 10.0 after 0.5M thiourea solution, wherein thiourea and Cd 2+ The molar ratio of the CdTe / CdS core / shell quantum dots with different particle sizes is obtained by controlling the refl...

Embodiment 2

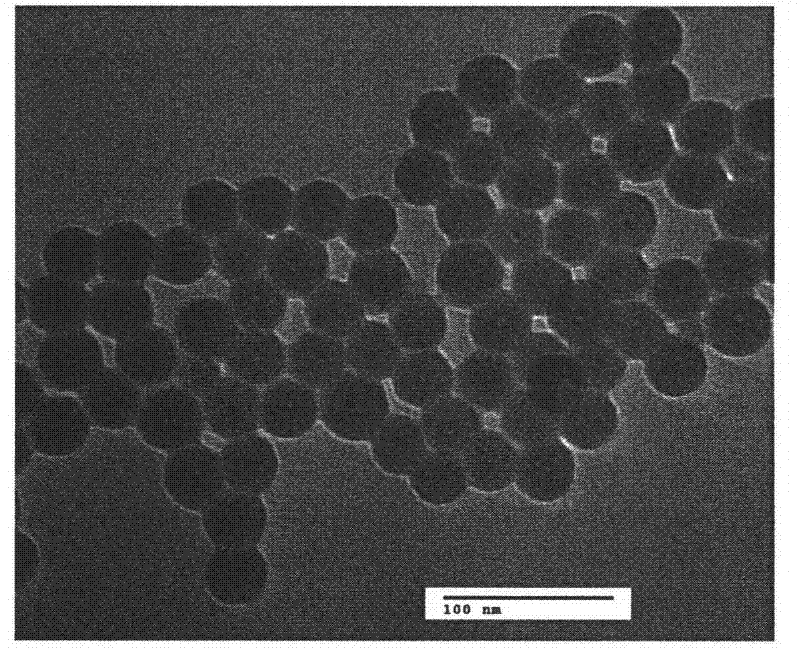

[0032] Take 500 μL of LCdTe / CdS core / shell quantum dots of Example 1, 1.8939 g of OP-5, 1.77 mL of cyclohexane, and 1.8 mL of n-hexanol in an autoclave, and quickly add 25 wt% 250 μL of ammonia water under stirring, and add after half an hour 100 μL tetraethyl orthosilicate (TEOS), replace the air with nitrogen three times, raise the system pressure to 0.8 atmospheres, and react at a low temperature of 0°C for 5 days; after the reaction, add acetone to the obtained mixed solution to precipitate the obtained fluorescence Nanoparticles, purified by low-temperature ultracentrifugation and washed with acetone ethanol to obtain CdTe / CdS / SiO with a particle size of about 20nm 2 Composite fluorescent nanoparticles with a quantum yield of 31%.

Embodiment 3

[0034] Take 500 μL of LCdTe / CdS core / shell quantum dots of Example 1, 1.8939 g of OP-5, 1.77 mL of cyclohexane, and 1.8 mL of n-hexanol in an autoclave, and quickly add 25 wt% 250 μL of ammonia water under stirring, and add after half an hour 100 μL tetraethyl orthosilicate (TEOS), replace the air with nitrogen three times, raise the system pressure to 1 atmosphere, and react at a low temperature of 0°C for 5 days; after the reaction, add acetone to the obtained mixed solution to precipitate the obtained fluorescence Nanoparticles, purified by low-temperature ultracentrifugation and washed with acetone ethanol to obtain CdTe / CdS / SiO with a particle size of about 22nm 2 Composite fluorescent nanoparticles with a quantum yield of 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com