Gel polymer electrolyte membrane for lithium ion secondary battery and preparation method of gel polymer electrolyte membrane

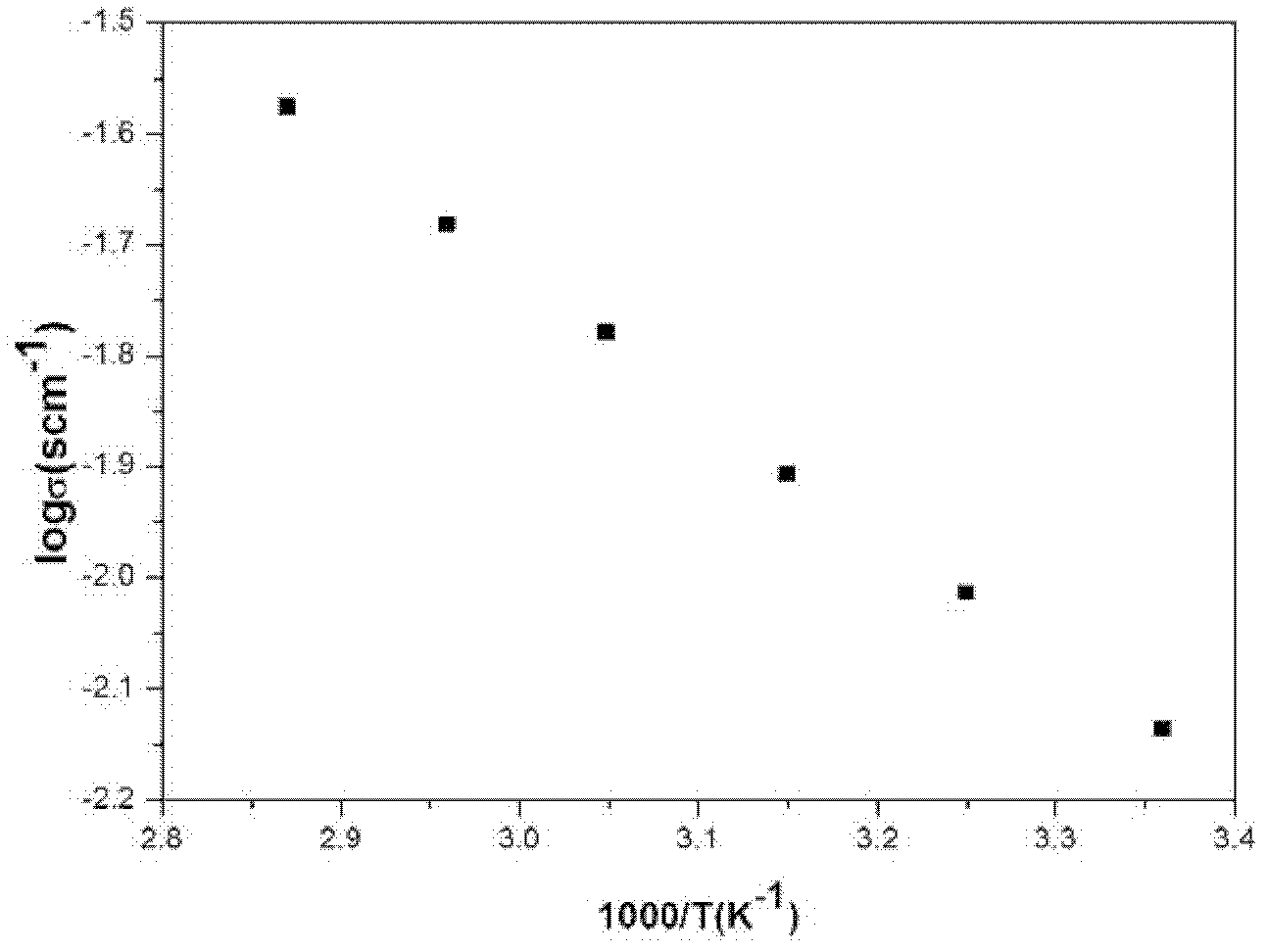

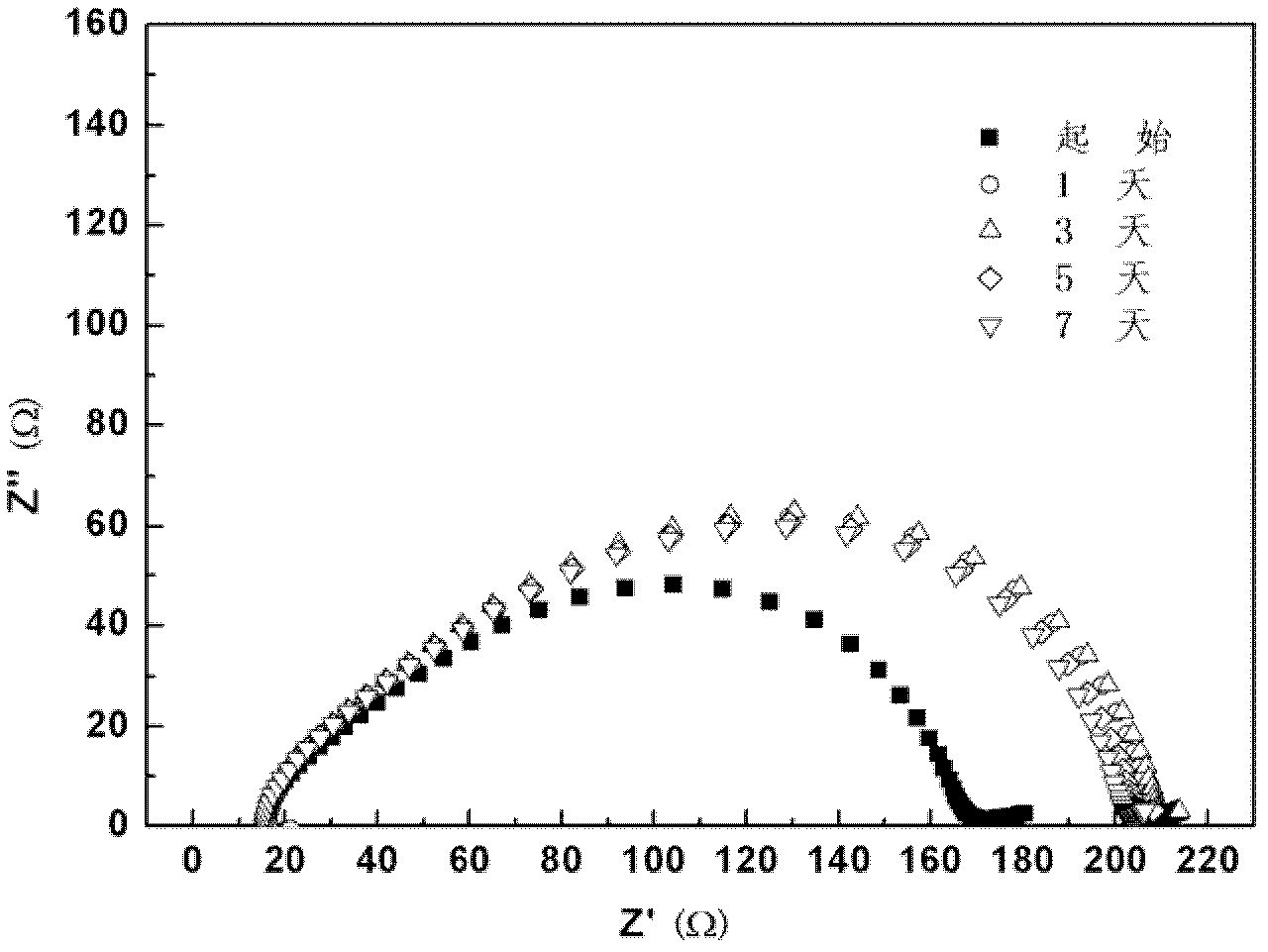

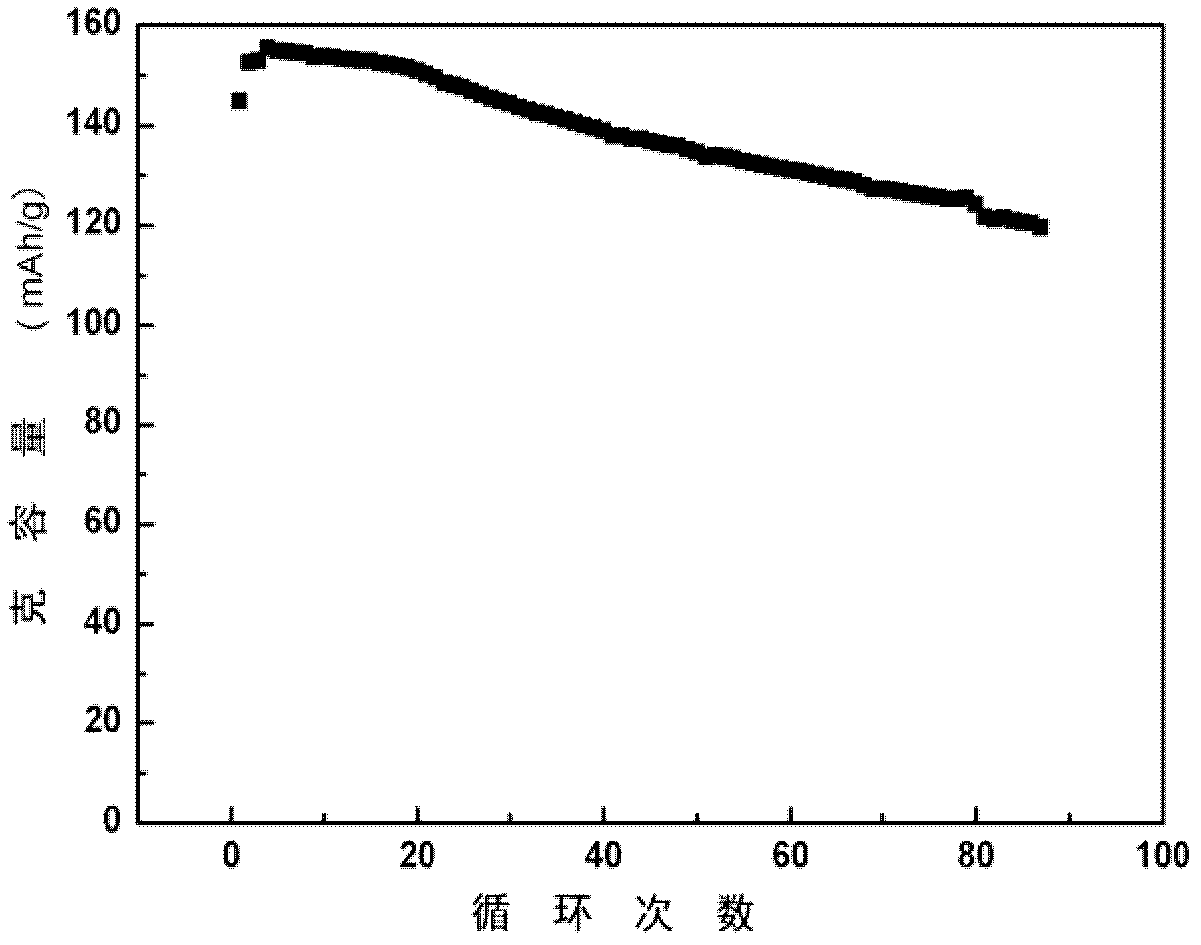

A technology of gel polymer and electrolyte membrane, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of large interface resistance, poor affinity of electrolyte, and easy leakage of electrolyte, so as to reduce production costs, The effect of high ionic conductivity and excellent interfacial stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Fluoropolymer solution (Shandong Dongyue Group, ion exchange capacity is 1.18mmol / g, number average molecular weight is 150,000, solvent N, the mass fraction of N-dimethylformamide is 70%), in The polymer electrolyte membrane is prepared by solution casting at 100°C. Wherein the chemical structural formula of the fluoropolymer is as follows:

[0039]

[0040] Wherein m and n are respectively integers of 1 to 10000; and m / (m+n)=55% to 90%;

[0041] (2) Heat the polymer electrolyte membrane with 5% hydrogen peroxide at a temperature of 80°C for 1 hour, then heat it with deionized water at a temperature of 80°C for 1 hour, and then heat it with 2mol / L sulfuric acid solution at 80°C heating at low temperature for 1 hour, and finally heating with deionized water at a temperature of 80° C. for 1 hour to obtain a pretreated polymer electrolyte membrane.

[0042](3) Immerse the pretreated polymer electrolyte membrane in a 2mol / L lithium hydroxide solution, heat and ref...

Embodiment 2

[0050] (1) Fluoropolymer solution (Shandong Dongyue Group, ion exchange capacity is 0.91mmol / g, number average molecular weight is 80,000, solvent N, the mass fraction of N-dimethylacetamide is 70%), in A polymer electrolyte membrane is prepared by solution casting at 160°C. Wherein the chemical structural formula of the fluoropolymer is as follows:

[0051]

[0052] Wherein m and n are integers of 1 to 10000 respectively, and m / (m+n)=55% to 90%;

[0053] (2) Heat the polymer electrolyte membrane with 1% hydrogen peroxide at a temperature of 100°C for 0.5 hours, then heat it with deionized water at a temperature of 100°C for 0.5 hours, and then heat it with 1mol / L sulfuric acid solution at 100°C heating at low temperature for 0.5 hours, and finally heating with deionized water at a temperature of 100°C for 0.5 hours to obtain a pretreated polymer electrolyte membrane.

[0054] (3) Immerse the pretreated polymer electrolyte membrane in a 1mol / L lithium hydroxide solution, ...

Embodiment 3

[0061] (1) Fluorine-containing polymer solution (Shandong Dongyue Group, ion exchange capacity is 0.98mmol / g, number average molecular weight is 170,000, and the mass fraction of solvent dimethyl sulfoxide is 60%) is passed through at 100°C The method of solution casting to form a membrane is prepared into a polymer electrolyte membrane. Wherein the chemical structural formula of the fluoropolymer is as follows:

[0062]

[0063] Wherein m and n are integers of 1 to 10000 respectively, and m / (m+n)=55% to 90%;

[0064] (2) Heat the polymer electrolyte membrane with 5% hydrogen peroxide at 60°C for 1 hour, then heat it with deionized water at 60°C for 1.5 hours, and then heat it with 2mol / L sulfuric acid solution at 60°C heating at low temperature for 1.5 hours, and finally heating with deionized water at 60° C. for 1.5 hours to obtain a pretreated polymer electrolyte membrane.

[0065] (3) Immerse the pretreated polymer electrolyte membrane in a 2mol / L lithium hydroxide so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com