Method for preparing surface functionalized polymer microspheres

A technology of polymer microspheres and surface functionalization, which is applied in the field of preparation of polymer microspheres, can solve the problems of strong radiation, large heat release, inconvenient operation, etc., and achieves the effects of safe operation, simple equipment and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing surface-functionalized polymer microspheres, comprising the following steps:

[0026] 1) Add the azo compound initiator and dispersant to the mixed solvent with a volume ratio of ethanol and water of 1:1-1.5, and disperse fully by ultrasonic to obtain a solution;

[0027] 2) Add functional monomers to the solution obtained in step 1), and disperse fully by ultrasonic to obtain a solution;

[0028] 3) The solution obtained in step 2) was irradiated with an 8W ultraviolet lamp for 24-36 hours to initiate the reaction. After the reaction, the emulsion product was centrifuged, poured off the supernatant, added deionized water, and blown the bottom white precipitate with a dropper. Disperse, make it redisperse, centrifuge and wash again, pour off the supernatant. The washing process is repeated for 5-6 times, and the washed microspheres are redispersed in deionized water and stored in the form of a suspension to obtain surface-functionalized polymer m...

Embodiment 1

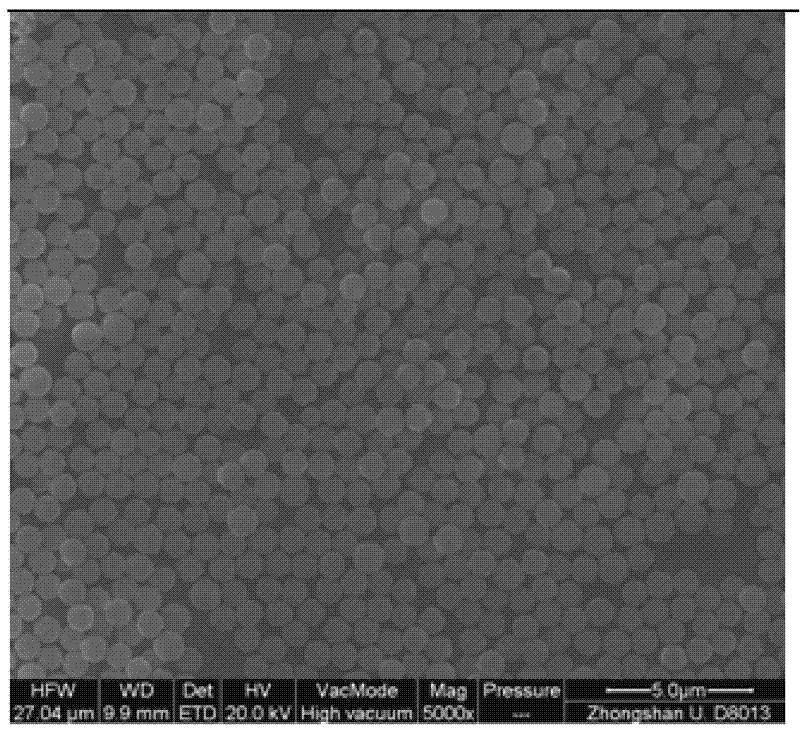

[0032] Take 0.2g of azobisisobutyronitrile and 1.05g of polyvinylpyrrolidone in a 150mL Erlenmeyer flask, add 25mL of absolute ethanol and 25mL of deionized water, and ultrasonically oscillate for 12min to obtain a homogeneous solution, then add 5mL of methacrylic acid methyl ester and 0.5 g of acrylamide, and then continue to sonicate for 15 min, and finally seal the Erlenmeyer flask, and irradiate it with an 8W ultraviolet lamp for 24 h under the action of magnetic stirring. After the reaction, the emulsion product was centrifuged at a speed of 3500 rpm for 15 minutes. After pouring off the supernatant, deionized water was added and the bottom white precipitate was blown away with a dropper to redisperse it, and then centrifugally washed. Pour off the supernatant. Repeat the washing process, wash 6 times, redisperse the washed microspheres in deionized water, and store them in the form of suspension, so that the P(MMA-co-AM) microspheres with amide groups on the surface are ...

Embodiment 2

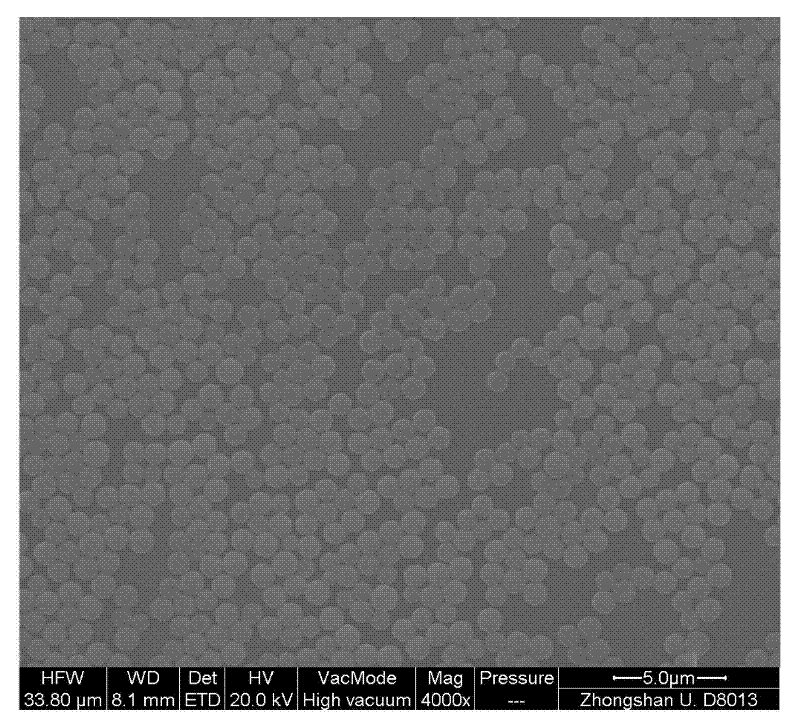

[0034] Weigh 0.2067g of azobisisobutyronitrile and 1.03g of polyvinylpyrrolidone into a 150mL Erlenmeyer flask, add 20mL of absolute ethanol and 30mL of deionized water, and ultrasonically oscillate for 20min to obtain a homogeneous solution, then add 1.25mL of formazan methyl acrylate and 0.106 mL of methacrylic acid, and then continue to sonicate for 5 minutes, and finally seal the conical flask, and irradiate it with an 8W ultraviolet lamp for 24 hours under the action of magnetic stirring. After the reaction, the emulsion product was centrifuged at a speed of 3000 rpm for 15 minutes. After pouring off the supernatant, deionized water was added and the white precipitate at the bottom was blown away with a dropper to redisperse it, and then washed by centrifugation. Pour off the supernatant. The washing process was repeated for 5 times, and the washed microspheres were redispersed in deionized water and stored in the form of a suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com