Curing agent for salinized sludge to achieve soil hardening and applications thereof

A technology of curing agent and saline soil, applied in the field of high-efficiency soil curing agent, can solve the problems of low economic benefit, high cost, unsatisfactory effect, etc., and achieve simple production process, convenient construction, reduced floor space and environmental impact. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the curing agent for saline silt soil hardening, comprises the following steps:

[0030] Weigh each raw material according to the following parts by mass: 0.8-1.2 parts of high alumina cement, 0.3-0.4 parts of calcium carbonate, 0.2-0.3 parts of talcum powder, 0.1-0.2 parts of water reducing agent, 6-7 parts of lime, sulfur-containing mixture 0.2 to 0.3 parts, 0 to 0.1 parts of β-naphthalenesulfonic acid formaldehyde sodium salt condensate, and mix the above-mentioned raw materials that have been weighed to obtain a curing agent for hardening saline silt soil.

[0031] The above sulfur-containing mixture is preferably a mixture of calcium sulfide, calcium sulfate and magnesium sulfate.

[0032] The above-mentioned lime is preferably quicklime powder.

[0033] The method for the hardening treatment of saline silt soil comprises the following steps:

[0034] 1) Mix the above curing agent and saline soil evenly, the mass ratio of curing agen...

Embodiment 1

[0052] Example 1: Preparation method of curing agent for saline silt soil hardening

[0053] Weigh each raw material according to the following parts by mass: 1 part of high alumina cement, 0.34 part of calcium carbonate, 0.28 part of talcum powder, 0.18 part of water reducing agent, 6.8 parts of quicklime powder, sulfur-containing mixture (calcium sulfide, calcium sulfate and magnesium sulfate mixture) 0.24 parts, β-naphthalenesulfonic acid formaldehyde sodium salt condensate 0.1 part, mix the above-mentioned raw materials that have been weighed, and then obtain the curing agent for saline silt soil hardening.

Embodiment 2

[0054] Example 2: Preparation method of curing agent for saline silt soil hardening

[0055] Weigh each raw material according to the following parts by mass: 1 part of high alumina cement, 0.34 part of calcium carbonate, 0.28 part of talcum powder, 0.16 part of water reducing agent, 6.2 parts of quicklime powder, sulfur-containing mixture (calcium sulfide, calcium sulfate and magnesium sulfate mixture) 0.28 parts, β-naphthalenesulfonic acid formaldehyde sodium salt condensate 0.1 part, mix the above-mentioned raw materials that have been weighed, and then obtain the curing agent for saline silt soil hardening.

PUM

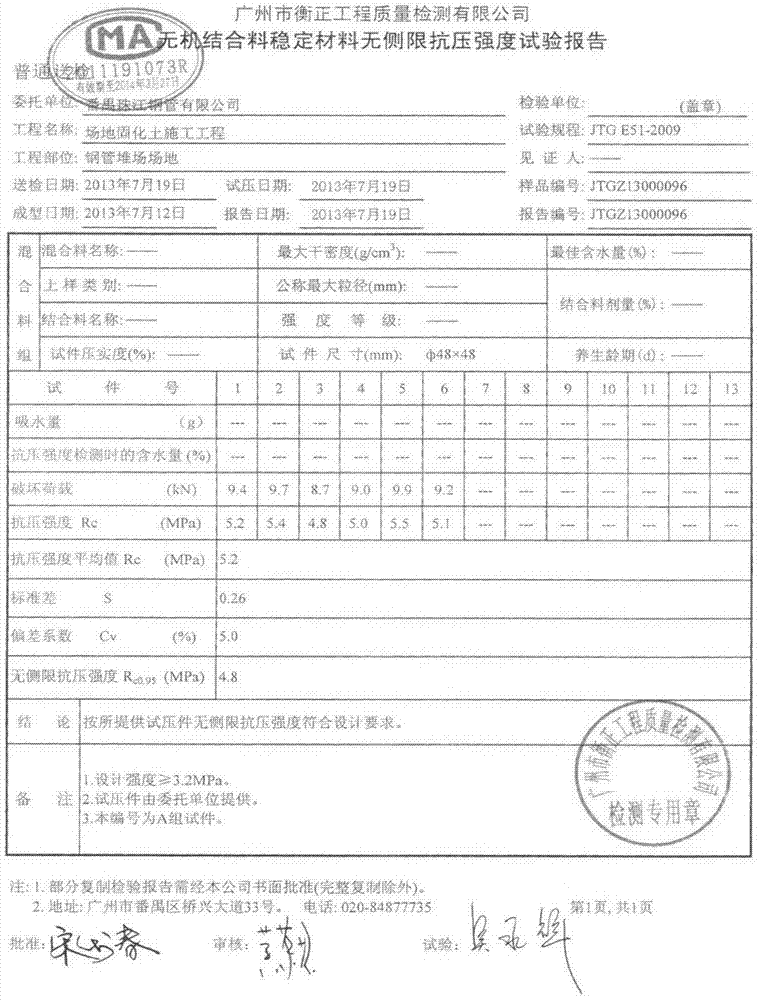

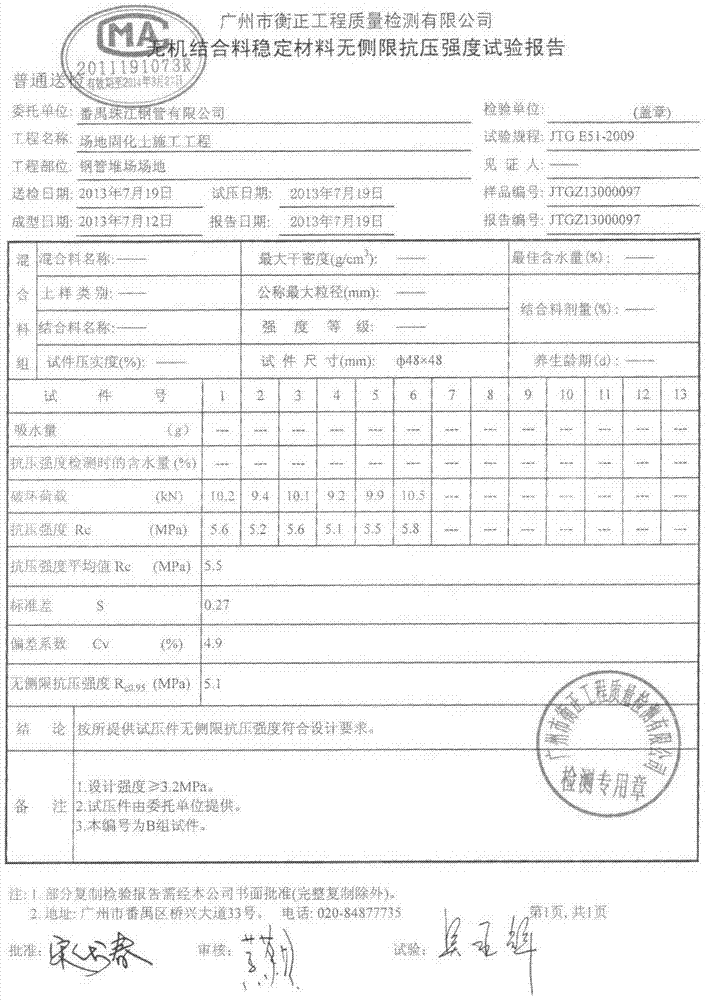

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com