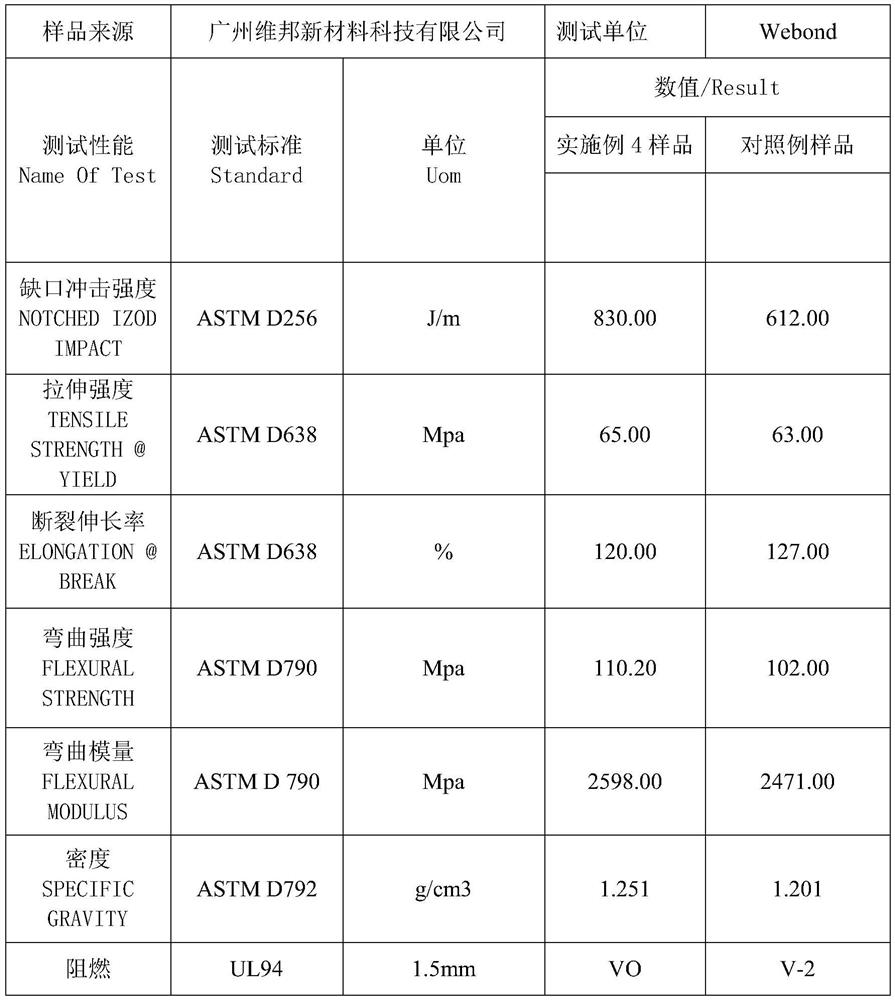

Self-isolation fireproof flame-retardant PC and PBT composite material

A composite material, fire-resistant and flame-retardant technology, applied in the direction of flame-retardant fibers, conjugated synthetic polymer artificial filaments, fiber treatment, etc., can solve the problems of acid-base corrosion resistance, aging resistance, degradation, etc., to achieve Effect of Improving Notched Impact Strength Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation from Isolated Flashing Layers

[0028] In the present embodiment, since the isolating flame retardant material is a powdery material, 700 g of ordinary PC resin, 100GPBT resin, main flame retardant 30g, hydraulic flame retardant 2g, sodium carbonate 10g, silica 10g, magnesium oxide 30g Mixed, placed in a ball mill and pulverizing a blended part.

Embodiment 2

[0029] Example 2 Preparation of PC, PBT alloy fiber cloth

[0030] PC resin 300g, PBT resin 600g, toughen 20g, main anti-oxygen 3g, auxiliary antioxidant 4g, inner lubricant 20g, outer lubricant 4g, anti-dripper 10g, extruded fiber, textile Sub-shaped material.

Embodiment 3

[0031] Example 3 Preparation of a low PBT content of PC, PBT alloy filled powder

[0032] PC resin 800g, PBT resin 100g, toughen 10g, main anterior oxygen 3g, an auxiliary antioxidant 4g, inner lubricant 3g, outer lubricant 20g, anti-dripper 10g is placed in a ball mill The PC of the low PBT content is obtained, and the PBT alloy is filled with powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com