Application of an electrocatalyst in the anode of proton exchange membrane fuel cell

A technology of proton exchange membrane and electrocatalyst, which is applied in battery electrodes, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of commercial application gap and achieve fast reduction, Excellent hydrogen oxidation activity, narrow distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: get 67.8mL Pd content and be the PdCl of 2.36mg / mL 2 Add hydrochloric acid solution in the three-necked flask, add 300mL ethylene glycol, then add 5mL 37wt% concentrated ammonia water, stir for 5 minutes, the solution becomes colorless, then add 10.1mL Pt content of 3.94mg / mL H 2 PtCl 6 Aqueous solution, then add 800mg Vulcan XC-72R carbon powder, disperse evenly, add 200mL NaBH drop by drop 4 10mg / mL NaBH 4 Aqueous solution, stirred for 3 hours, settled for 40 hours, centrifuged, washed, and dried in a vacuum oven at 60°C for 12 hours to obtain the catalyst 20% Pd 16 Pt 4 / XC-72.

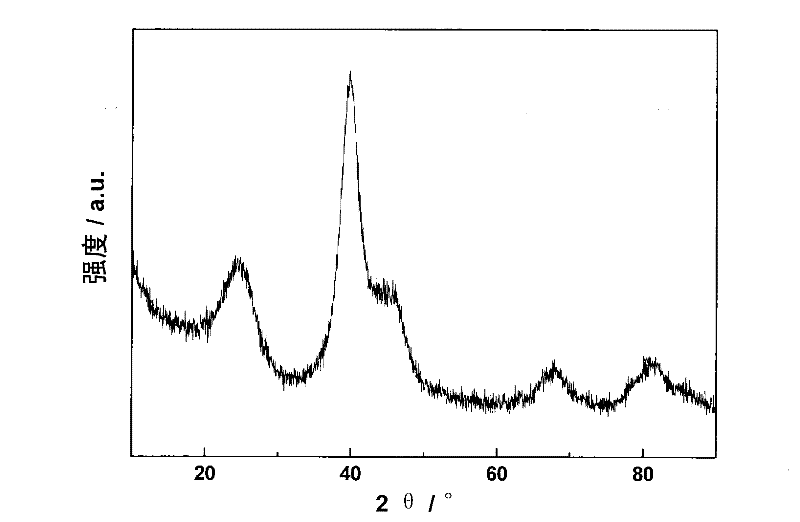

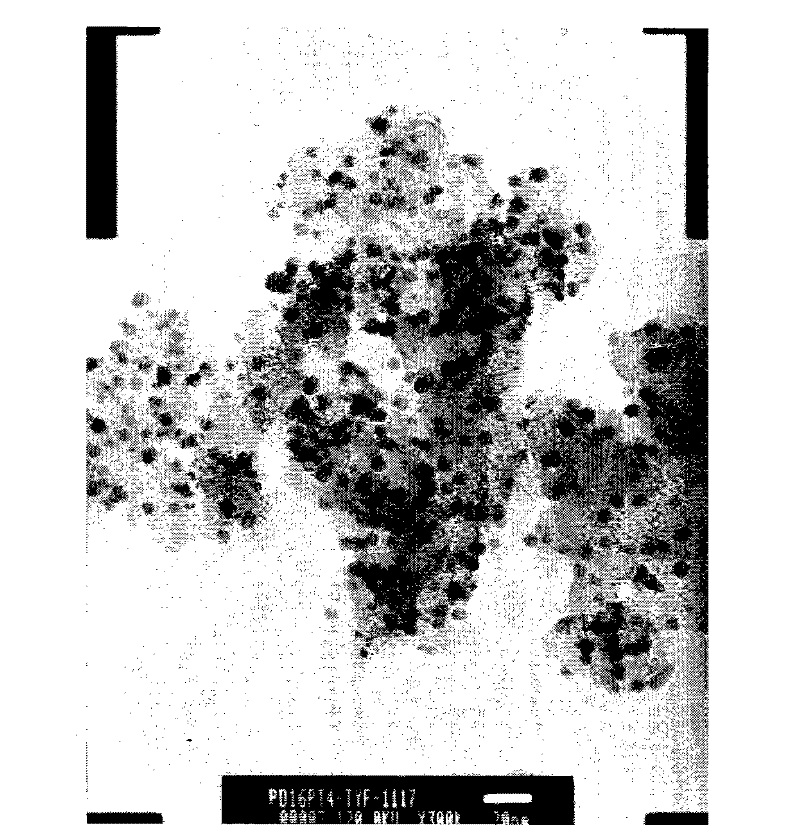

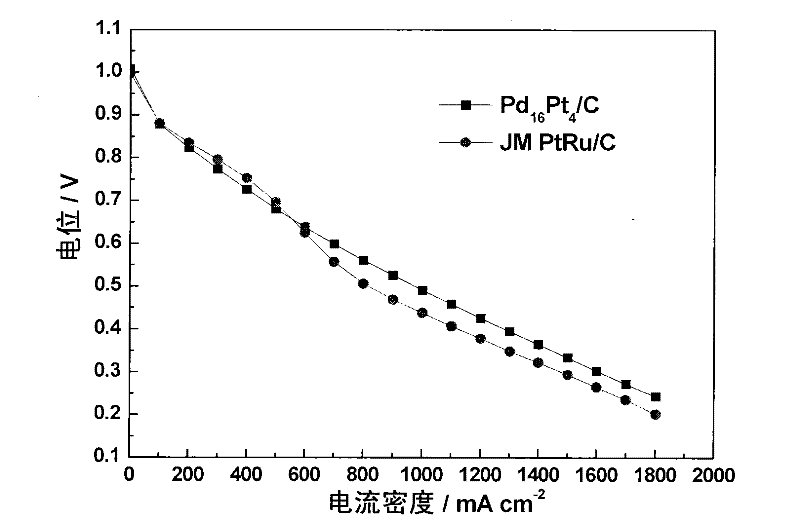

[0039] Depend on figure 1 It can be seen from the XRD that the alloy exists in a face-centered cubic (fcc) structure, without diffraction peaks of oxides, and the grain size calculated by Scherrer's formula is 2.8nm. Depend on figure 2 It can be seen from the TEM that the metal particles of the obtained catalyst are small, and the average particle diameter obtained by s...

Embodiment 2

[0040] Embodiment 2: get 67.8mL Pd content and be the PdCl of 2.36mg / mL 2 Add the hydrochloric acid solution into the three-necked flask, add 300mL of ethylene glycol and 5mL of concentrated ammonia water, stir for 5 minutes, the solution becomes colorless, then add 7.6mL of H2O with a Pt content of 3.94mg / mL 2 PtCl 6 aqueous solution, then add 3.4 mL of RuCl with a Ru content of 2.94 mg / mL 3 Aqueous solution, then add 800mg Vulcan XC-72R carbon powder, disperse evenly, add 200mL NaBH drop by drop 4 10mg / mL NaBH 4 Aqueous solution, stirred for 3 hours, settled for 40 hours, centrifuged, washed, and dried in a vacuum oven at 80°C for 12 hours to obtain the catalyst 20% Pd 16 Pt 3 Ru 1 / XC-72.

Embodiment 3

[0041] Embodiment 3: get 80.5mL Pd content and be the PdCl of 2.36mg / mL 2 Add hydrochloric acid solution into a three-necked flask, add 300mL ethylene glycol, then add 5mL concentrated ammonia water, stir for 5 minutes, the solution becomes colorless, then add 2.5mL H2O with a Pt content of 3.94mg / mL 2 PtCl 6 Aqueous solution, then add 300mg Vulcan XC-72R carbon powder, disperse evenly, add 300mL NaBH drop by drop 4 KBH at 8mg / mL 4 Aqueous solution, stirred for 3 hours, settled for 40 hours, centrifuged, washed, and dried in a vacuum oven at 100°C for 24 hours to obtain the catalyst 40% Pd 19 Pt 1 / XC-72.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com