An optimized scheme for the comprehensive utilization of milk thistle

An optimization scheme and technology of silymarin, which is applied to the protein composition, application, and digestive system of vegetable seeds, can solve the problems of large amount of organic solvent, poor quality of silymarin, and long extraction cycle, so as to simplify production steps and reduce equipment, the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

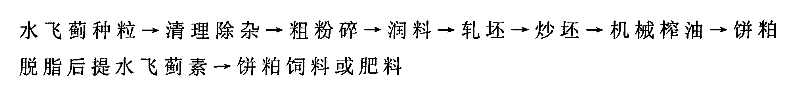

Method used

Image

Examples

Embodiment 1

[0040] Add 250Kg of milk thistle seeds, add 2000L of 75% edible ethanol, extract by heating and reflux for 2hr., and filter. Add 2000L and 1300L to the filter residue, and then reflux and extract twice, each time for 1.5hr. Combine the ethanol extracts. After the residue is de-alcoholized and dried, the oil is pressed, and the cake is used for preparing protein or processing feed.

[0041] The ethanol extract is decompressed to recover an appropriate amount of solvent, and flows through 300Kg polar adsorption resin HPD-600 at a speed of 1.5-2BV / hr. After washing with deionized water to remove impurities, then press 1-1.5BV with 5-6BV70% ethanol The target substance is eluted at a speed of / hr. The eluate is concentrated under reduced pressure until it has no alcohol smell, centrifugally filtered, and the centrifuge is dried and crushed under reduced pressure at 60°C to obtain 4.25Kg of silymarin, which is detected by HPLC. and B) 33%.

Embodiment 2

[0043] Add 300Kg of milk thistle seeds, add 2400L of 75% edible ethanol, extract by heating and reflux for 2hr., and filter. Add 1800L and 1800L to the filter residue, and then reflux and extract twice, each time for 1.5hr. Combine the ethanol extracts. After the residue is de-alcoholized and dried, the oil is pressed, and the cake is used for preparing protein or processing feed.

[0044] The ethanol extract was decompressed to recover the solvent to an appropriate amount, and flowed through 300Kg polar adsorption resin ADS-7 at a speed of 1.5-2BV / hr. The target substance was eluted at a speed of BV / hr. The eluate was concentrated under reduced pressure until it had no alcohol smell, and was centrifugally filtered. The centrifuge was dried and crushed under reduced pressure at 60°C to obtain 5.75Kg of silymarin, which was detected by HPLC ( A and B) 31%.

Embodiment 3

[0046] Add 250Kg of milk thistle seeds, add 2000L of 80% edible ethanol, extract by heating and reflux for 2hr., and filter. Add 1500L and 1500L to the filter residue, and then reflux and extract twice, each time for 1.5hr. Combine the ethanol extracts. After the residue is de-alcoholized and dried, the oil is pressed, and the cake is used for preparing protein or processing feed.

[0047] The ethanol extract is decompressed to recover the solvent to an appropriate amount, and flows through 250Kg polar adsorption resin LSA-7 at a speed of 1.5-2BV / hr. The target substance was eluted at a speed of BV / hr. The eluate was concentrated under reduced pressure until it had no alcohol smell, and was centrifugally filtered. The centrifuge was dried and crushed under reduced pressure at 60°C to obtain 4.31Kg of silymarin, which was detected by HPLC ( A and B) 31.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com