Method and device for remediating polluted soil and treating solid waste by using electric energy

A technology for solid waste and polluted soil, applied in the field of remediation of polluted soil and treatment of solid waste, can solve the problems of economic feasibility not as good as steam extraction and microbial remediation technology, not suitable for organic polluted soil, low hydrogen production rate, etc. The uniformity of temperature distribution is high, the repair effect is improved, and the repair time is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

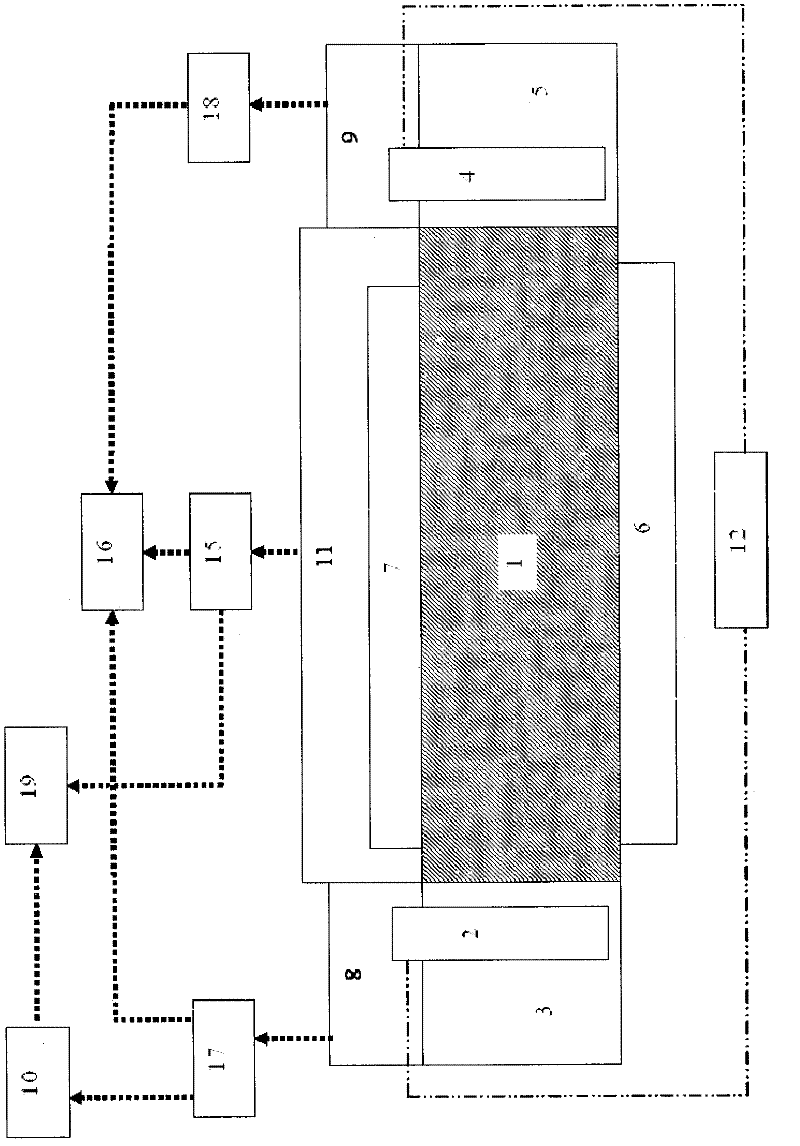

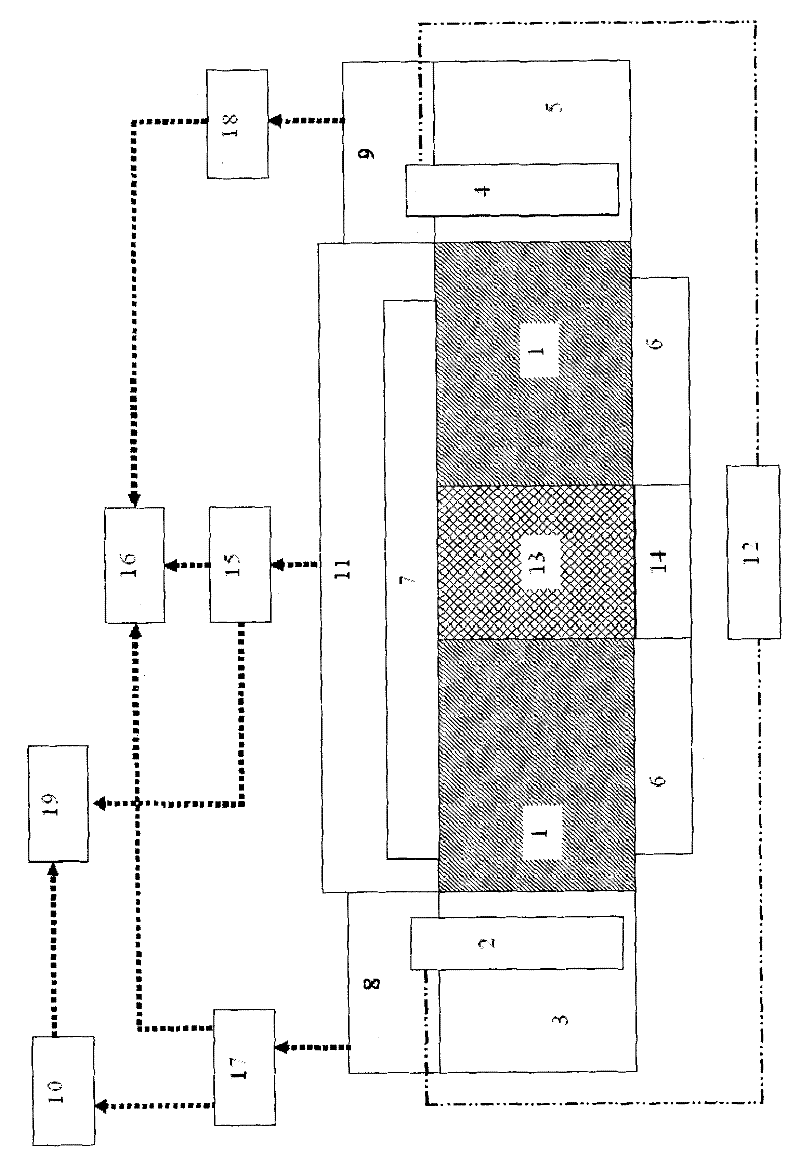

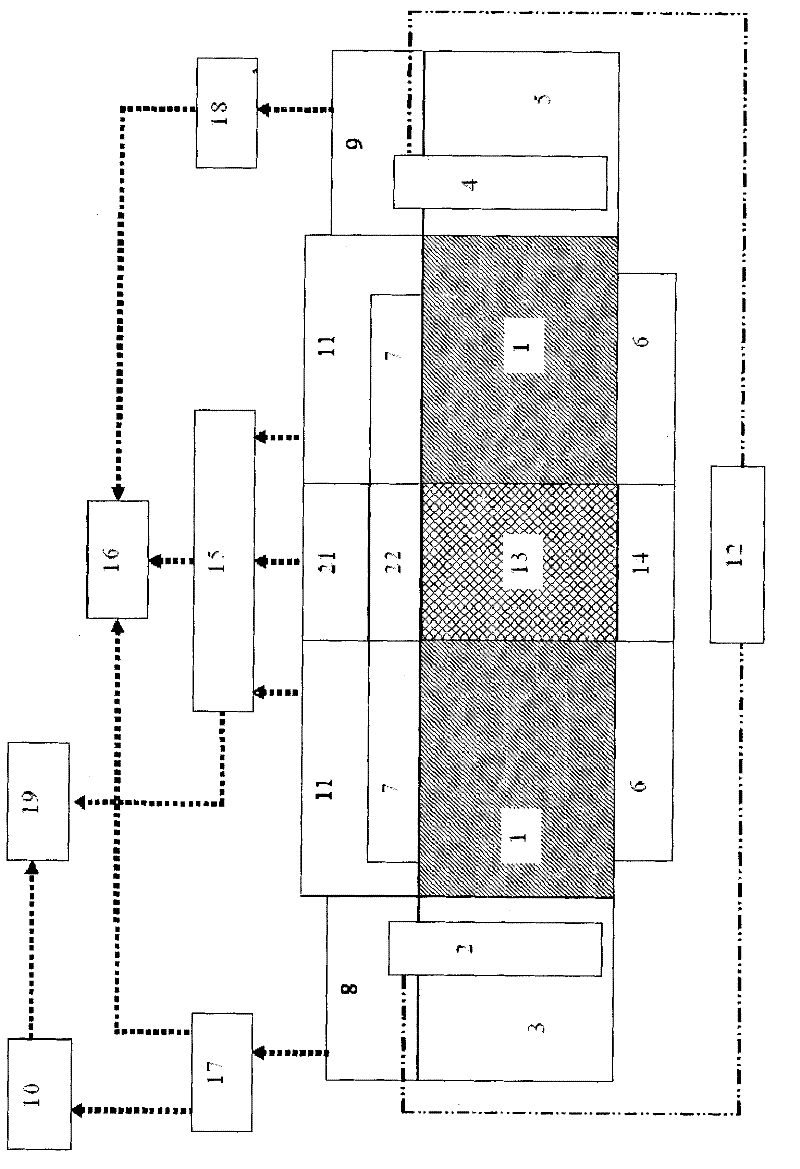

[0022] (1) According to Figure 1 to Figure 4 As shown, the equipment is assembled at the repair site;

[0023] (2) Use manual or equipment to turn and mix the soil / solid waste to make it loose and uniform, and remove large stones, tree roots and metal objects at the same time. If the soil / solid waste has poor water permeability, it can be mixed with sand, Sawdust or other solid wastes that can increase water permeability (such as phosphogypsum, etc.); if salt, acid, complexing agent and other chemicals need to be added in advance, they should also be added at this time and mixed evenly;

[0024] (3) Put the above-mentioned pretreated soil / solid waste into the device, and the thickness generally does not exceed 1m (for volatile organic pollutants, the thinner the soil / solid waste layer, the better. In the model, the thickness of the soil / solid waste can be less than 0.1m), and do not compact, the top is repaired and leveled, and the collection layer 7 is laid (if the pollutan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com